Armored cables are essential in electrical installations that demand extra protection from mechanical damage, moisture, and environmental stress. Whether you're wiring a building, running underground power lines, or protecting circuits in industrial areas, selecting the right type of armored cable is critical for safety, performance, and compliance.

In this guide, we’ll walk through:

What armored cable is

Main types of armored cable

Key differences between them

Where each type is used

Buying tips

🔍 What Is an Armored Cable?

An armored cable is an electrical cable with an added protective layer—typically made of steel or aluminum—to shield conductors from physical damage. The armor layer can be:

Steel Wire Armour (SWA)

Steel Tape Armour (STA)

Aluminum Wire Armour (AWA)

Interlocked armor (typically used in the US)

Armored cables are commonly used in:

Industrial power distribution

Outdoor or underground installations

Harsh or hazardous environments

Direct burial applications

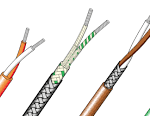

🧱 Main Types of Armored Cable

Here are the most widely used types of armored cables and their features:

1. SWA Cable (Steel Wire Armoured Cable)

Core: Copper or aluminum conductors

Armor: Galvanized steel wire

Sheath: PVC or LSZH

Voltage rating: 600/1000V

Use: Power transmission in fixed installations—often underground or outdoor

🧰 Common in: UK, Europe

📦 Example: 6mm 3 core SWA cable

2. STA Cable (Steel Tape Armored Cable)

Armor: Steel tape (instead of wire)

More flexible, but less resistant to impact compared to SWA

Typically used for indoor installations or ducts

📌 Best for: Low mechanical stress zones

🛡️ Not ideal: Direct burial or high-impact areas

3. AWA Cable (Aluminum Wire Armoured Cable)

Used with single-core cables

Prevents magnetic interference (eddy currents)

Lightweight vs SWA

💡 Typical in: High-voltage single-core systems

⚙️ Standard: IEC 60502-1

4. BX Cable (US Terminology)

Type AC cable (Armored Cable)

Flexible metallic sheath, often used in residential and commercial buildings

Includes bonding strip for grounding

🏠 Used in: Indoor wiring of lighting and power circuits

5. MC Cable (Metal-Clad Cable)

Stronger and safer alternative to BX

Aluminum interlocked armor

Can include multiple conductors and ground

Suitable for wet locations, concealed or exposed

📏 Common standards: UL 1569, NEC Article 330

6. Lead Sheathed Armored Cable

Additional lead layer to resist moisture and chemical corrosion

Often used in underground, oil & gas, or chemical industries

🛢️ Highly resistant to oil, acid, and alkali environments

7. Fire-Resistant Armored Cables

Often include mica tape or mineral insulation

Maintains circuit integrity during fire

Found in emergency systems (e.g., alarms, smoke extractors)

🚨 Standards: IEC 60331, BS 6387

🔄 Comparison Table: SWA vs STA vs MC vs BX

| Feature | SWA | STA | MC (US) | BX (US) |

|---|---|---|---|---|

| Armor Type | Steel wire | Steel tape | Interlocked | Interlocked |

| Rigidity | Rigid | Flexible | Flexible | Semi-flex |

| Indoor/Outdoor | Both | Indoor | Both | Indoor only |

| Direct Burial | Yes | No | Some types | No |

| Grounding Conductor | Separate | Separate | Built-in | Bonding strip |

| Common Voltage Range | 600/1000V | 600V | 600V–5kV | 600V |

🧰 Application Scenarios

SWA Cable: Outdoor lighting, buried power lines, building mains

MC Cable: Commercial buildings, industrial equipment

BX Cable: Home remodels, concealed wall installations

Lead Sheathed Cable: Refineries, chemical plants

Fireproof Armored Cable: Emergency lighting, fire alarms

✅ Tips for Choosing the Right Armored Cable

Check your voltage and current needs

Match armor type to environmental conditions (e.g., corrosion, moisture)

Follow local electrical codes

Consider mechanical protection level needed

Use proper cable glands or termination kits for armored types

📌 Final Thoughts

Understanding the different types of armored cable helps ensure a safe, compliant, and durable electrical system. From SWA to MC, each has its own purpose and application—choosing the right one saves both cost and trouble in the long run.