As data centers evolve to support increasingly complex AI accelerator clusters, system architects are facing an unprecedented set of challenges. In the next few years, the expansion of AI computing infrastructure will hinge on three critical goals:

Delivering higher performance to meet exploding bandwidth demand

Scaling computing power while controlling costs

Continuing to improve energy efficiency

These three imperatives keep network operators awake at night — and neither copper nor optical fiber alone can fully address them.

The Terabit Era Is Testing the Limits of Copper and Fiber

Generative AI and large language models (LLMs) are driving data center interconnects far beyond traditional capacities. Network bandwidth requirements have already doubled from 400G to 800G, with 1.6T and even 3.2T speeds on the horizon.

To meet these demands, data centers currently rely on copper cables for short-reach and optical links for long-reach connections. Yet both face serious limitations as data rates approach terabit speeds.

Copper: Reliable but Physically Constrained

Copper has long been the preferred medium for short-distance interconnects due to its low cost, simplicity, and reliability. However, at extremely high frequencies, copper faces fundamental physical barriers.

The skin effect causes severe channel loss at high data rates, which limits reach. To compensate, thicker conductors are required — resulting in cables that are too heavy, rigid, and space-consuming for modern high-density data centers.

Simply put, copper cannot scale efficiently beyond 800G. At 1.6T speeds and above, copper cables become too short and bulky to be practical within server racks or AI clusters.

Fiber Optics: High Speed at a High Cost

To overcome the reach limitations of copper, many hyperscalers have turned to optical interconnects such as Active Optical Cables (AOCs).

AOCs support longer transmission distances — often several kilometers — and their slimmer, lighter form factor simplifies deployment. However, optical links come with their own trade-offs:

Higher complexity due to optical DSPs, transimpedance amplifiers (TIAs), laser drivers, and lasers

Greater power consumption from electro-optical conversion

Thermal sensitivity and long-term reliability concerns

Significant cost premium — up to 5× higher than copper interconnects

In addition, optical DSP electronics introduce latency, undermining performance for latency-sensitive AI workloads. The combination of higher power and cost makes optical technology increasingly unsustainable for large-scale, AI-driven data centers.

The Third Option: e-Tube RF Interconnects

e-Tube RF Interconnects

To break through these limitations, a third interconnect solution has emerged — one that bridges the gap between copper and fiber:

the e-Tube scalable multi-terabit interconnect platform.

Instead of using metal or glass, e-Tube transmits high-speed data through a plastic waveguide using millimeter-wave (mmWave) radio frequency (RF) technology.

How e-Tube Works

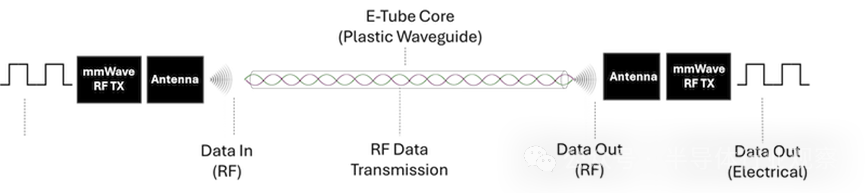

As illustrated in Figure 2, Active RF Cables (ARC) based on e-Tube technology integrate miniature mmWave RF transceivers at each end of the link. These devices upconvert electrical terabit data into RF signals, which propagate through the e-Tube’s low-loss plastic core.

At the receiving end, complementary RF receivers downconvert the signal back to the electrical domain. To the connected systems, this process is entirely transparent — the ARC behaves just like a conventional electrical interconnect.

By replacing metal with plastic as the transmission medium, e-Tube achieves low-cost, low-loss, and high-efficiency data transfer — without the drawbacks of copper or optics.

Technical Advantages of the e-Tube Platform

e-Tube cables are made from low-density polyethylene (LDPE), a cost-effective and widely available plastic that avoids high-frequency loss effects seen in copper.

Combined with ultra-low-power RF transmitter and receiver ICs, the system delivers:

Energy efficiency: 3 pJ/bit — best-in-class

Latency: only a few picoseconds

Data rate scalability: from 56G to 224G and beyond

Performance Comparison

Compared with traditional copper and optical cables, e-Tube interconnects offer:

| Parameter | vs. Copper | vs. Optical Fiber |

|---|---|---|

| Cable reach | 10× longer | Comparable |

| Weight | 5× lighter | 2× lighter |

| Thickness | 2× thinner | Similar |

| Power consumption | 3× lower | 3× lower |

| Latency | 1,000× lower | 100× lower |

| Cost | 3× cheaper | 5× cheaper |

This makes e-Tube the ideal replacement for copper in short- and mid-reach interconnects — particularly for rack-to-rack and intra-rack connections in AI data centers.

Designed for Scalability and Compatibility

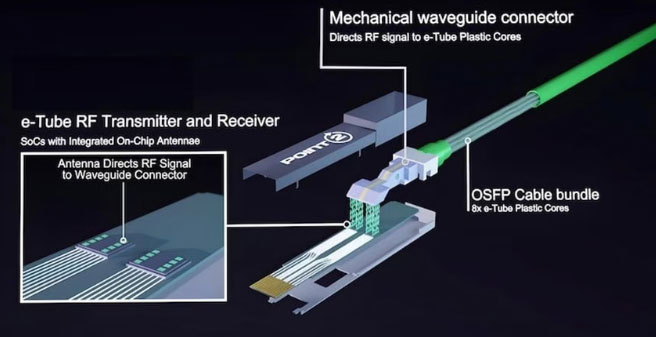

To accelerate adoption, e-Tube RF SoCs are manufactured using standard semiconductor processes and mature IC packaging technologies.

Designed for Scalability and Compatibility

The cable design follows industry-standard MSA (Multi-Source Agreement) form factors such as OSFP and QSFP-DD, ensuring compatibility with existing network infrastructure and flexibility across system designs.

This backward compatibility allows data center operators to integrate e-Tube technology seamlessly into their current ecosystem, without redesigning entire systems.

Powering the Next Generation of AI Infrastructure

As data center hardware rapidly evolves to support LLM and generative AI workloads, the demand for scalable, power-efficient, and cost-effective interconnects is becoming mission-critical.

Neither copper nor fiber alone can meet the combined requirements of bandwidth, energy efficiency, and scalability for future terabit networks.

The e-Tube RF interconnect represents a revolutionary step forward — combining the low cost and simplicity of copper with the speed and reach of optics, all while achieving unprecedented levels of power efficiency and latency performance.

With its unique combination of light weight, scalability, and affordability, e-Tube technology is poised to reshape the future of AI cluster connectivity — enabling next-generation data centers to scale efficiently toward 1.6T, 3.2T, and beyond.

⚡ Conclusion

Copper and fiber have defined data center interconnects for decades, but both are reaching their physical and economic limits in the terabit era.

e-Tube offers a third path — a plastic-based, RF-powered interconnect platform that delivers the bandwidth, efficiency, and scalability required by tomorrow’s AI-driven infrastructure.

For data centers preparing to scale their AI clusters, e-Tube is not just an alternative — it’s the future of high-speed connectivity.