Steel Wire Armoured (SWA) cable is one of the most widely used forms of mechanical-protection power cable in industrial, commercial, and outdoor electrical installations. While “armoured cable” is a broad category, SWA cable specifically refers to power cables protected by layers of galvanized steel wires, offering exceptional strength, durability, and impact resistance.

185mm 4 Core Steel Wire Armoured SWA Cable

This guide explains what steel wire armoured cable is, how it is built, where it is used, and how it compares with other types of armoured cables.

1. What Is Steel Wire Armoured Cable?

Steel Wire Armoured cable—commonly known as SWA cable—is a power cable reinforced with galvanized steel wires placed underneath the outer sheath.

Its purpose is to provide high mechanical protection while ensuring reliable power transmission in harsh or exposed environments.

SWA cable is typically manufactured according to standards such as BS5467 (PVC insulation) or BS6724 (LSZH insulation).

In simple terms:

SWA cable = electrical power cable + steel wire armor for mechanical protection.

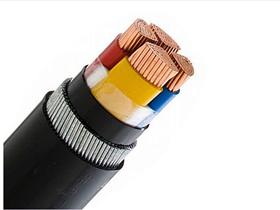

2. Structure of Steel Wire Armoured Cable (SWA Cable)

A typical SWA cable consists of the following layers:

① Copper or Aluminum Conductor

Usually Class 2 stranded copper

Aluminum options available for large power distribution cables

② Insulation

PVC, XLPE, or LSZH

XLPE is the most common due to its high temperature rating (90°C)

③ Inner Sheath / Bedding

Holds the insulated cores in place

Acts as a bedding layer for the armor wires

④ Steel Wire Armour (SWA)

Multiple galvanized steel wires helically wrapped around the bedding

Provides:

Impact resistance

Mechanical strength

Resistance to crushing, digging, and rodent damage

Additional earth fault capability (in some applications)

⑤ Outer Sheath

PVC or LSZH

Offers environmental, UV, moisture, and chemical resistance

3. Key Advantages of Steel Wire Armoured Cable

✅ Excellent Mechanical Protection

Can withstand severe external impact and pressure, making it ideal for underground or exposed use.

✅ High Tensile Strength

Suitable for installations where cables may be pulled over long distances.

✅ Improved Durability

The armor prevents damage from:

Construction activities

Rodents

Vibration

Crushing forces

✅ Versatile Installation Options

Can be laid:

Directly in the ground

In ducts and trays

On building exteriors

On cable ladders

In industrial facilities

✅ Reliable Power Transmission

XLPE insulation ensures better thermal performance and higher current-carrying capacity.

4. Common Applications of SWA Cable

SWA cable is widely used in:

Underground power distribution

Industrial machinery wiring

Outdoor lighting systems

Construction sites

Power to outbuildings (workshops, garages, sheds)

Commercial and public infrastructure

Water treatment plants

Mining and heavy-duty applications

Its rugged design makes it ideal for any environment where the cable may be physically stressed.

5. SWA Cable Voltage Ratings

Standard voltage ratings include:

0.6/1kV (Low Voltage) — most common

3.8/6.6kV — medium voltage variants available

Higher voltages possible depending on specification

6. SWA Cable vs. Other Armoured Cables

To distinguish clearly from your earlier “what is armoured cable” article,以下是重点对比:

🔹 SWA vs. AWA Cable

| Feature | SWA (Steel Wire) | AWA (Aluminum Wire) |

|---|---|---|

| Armour Material | Galvanized steel wires | Aluminum wires |

| Best for | Multi-core cables | Single-core cables |

| Magnetic? | Yes | No |

| Cost | Slightly higher | Lower |

🔹 SWA vs. STA Cable

| Feature | SWA | STA (Steel Tape Armoured) |

|---|---|---|

| Armor Type | Round steel wires | Steel tape |

| Flexibility | Higher | Lower |

| Mechanical Protection | Higher | Moderate |

| Applications | General-purpose LV | Mainly underground low-voltage |

🔹 SWA vs. NYY / Non-armoured Cable

| Feature | SWA Cable | NYY / Non-Armoured |

|---|---|---|

| Mechanical Protection | Very high | Low |

| Underground Use | Ideal | Not recommended unless in conduit |

| Cost | Higher | Lower |

7. Typical Specifications of Steel Wire Armoured Cables

Common SWA cable sizes include:

1.5mm² – 16mm² (lighting, small power circuits)

25mm² – 95mm² (industrial distribution)

120mm² – 300mm² (heavy power systems)

Conductors can be:

Copper (standard for LV power)

Aluminum (cost-effective for long runs)

Available in:

2-core, 3-core, 3.5-core, 4-core, and 5-core configurations

8. How SWA Cables Are Grounded

In many installations, the steel wire armour acts as an earth (ground) conductor.

However, this depends on the cable size and local electrical regulations.

In high-fault-current systems, a separate earth conductor may be required.

9. Conclusion: Why SWA Cable Matters

Steel Wire Armoured cable is a durable, reliable, and versatile solution for low-voltage power distribution in challenging environments. Its combination of mechanical protection, environmental resistance, and stable electrical performance makes it one of the most trusted industrial and outdoor cables worldwide.

Whether used underground, outdoors, or in demanding industrial sites, SWA cable ensures long-lasting and safe power delivery.