emc cable

What is an EMC Cable?

An EMC cable (Electromagnetic Compatibility cable) is a specially designed shielded cable engineered to prevent electromagnetic interference (EMI) and ensure electromagnetic compatibility in electronic systems. These cables feature advanced shielding techniques that protect sensitive signals from external electromagnetic disturbances while preventing stronger signals from leaking out and interfering with surrounding electronics.

EMC Shielding is any method used to protect a sensitive signal from external electromagnetic signals, or preventing a stronger signal from leaking out and interfering with surrounding electronics. EMC cables play a critical role in maintaining signal integrity and regulatory compliance across industrial, automotive, aerospace, and telecommunications applications.

Understanding EMC and EMI in Cable Applications

What is Electromagnetic Compatibility?

EMC is the ability of electrical or electronic devices to function properly in their intended electromagnetic environment, without introducing unwanted electromagnetic disturbance. In cable applications, this means ensuring that data transmission occurs without interference from external sources or creating interference for other systems.

The Role of EMI Shielding

The term EMC shielding refers to a variety of methods used to protect electronic devices from electromagnetic interference (EMI). Electromagnetic interference is unwanted, undesirable noise in an electrical circuit that's linked to an external source. EMC cables address this challenge through sophisticated shielding designs that contain and control electromagnetic fields.

Types of EMC Cable Shielding

Braided Shield Construction

The copper shielding braid is laid out all around (over a large area) and without gaps at the transition into the enclosure. The cable gland is connected to the metallic enclosure wall with low impedance. This comprehensive coverage provides excellent protection against electromagnetic interference.

Advanced Shielding Materials

EMC cables utilize various shielding materials including:

Copper Braided Shields: Provide excellent conductivity and flexibility for dynamic applications. The braided construction offers superior coverage while maintaining cable flexibility.

Aluminum Foil Shields: Offer complete coverage and are cost-effective for many applications. These provide excellent protection against high-frequency interference.

Combination Shields: Feature both braided and foil layers for maximum protection. This dual-layer approach combines the benefits of both shielding types.

Metalized Fabric Shields: Provide flexibility and conformability for complex routing requirements while maintaining effective EMI protection.

EMC Cable Performance Specifications

Coupling Resistance and Screening Attenuation

EMC protection is measured and stated using coupling resistance [mΩ/m] and/or screening attenuation [dB]. The coupling resistance of cables and wires is normally specified at a defined frequency of 30 MHz. By contrast, screening attenuation is used for high frequencies from 50 MHz.

These measurements help engineers select appropriate cables for specific electromagnetic environments and frequency ranges.

Frequency Response Characteristics

EMC cables are designed to handle various frequency ranges:

Low Frequency (30 MHz and below): Measured primarily by coupling resistance, these applications include power distribution and control systems.

High Frequency (50 MHz and above): Evaluated using screening attenuation measurements, covering data communications and RF applications.

Broadband Applications: Modern EMC cables often need to perform across wide frequency ranges to accommodate multiple signal types.

Industrial Applications of EMC Cables

Manufacturing and Automation

Industrial environments present unique EMC challenges due to:

- High-power machinery generating electromagnetic fields

- Variable frequency drives (VFDs) creating electrical noise

- Proximity of control and power cables

- Harsh environmental conditions requiring robust protection

Our flame retardant EMC cable type is CBPJP86/SC and fire resistant EMC cable type is CBPJP86/NC. Both types are produced by low smoke and halogen free thermosetting compound, so they feature low smoke, halogen free and flame retardant.

Marine and Offshore Applications

Marine environments require specialized EMC cables that provide:

- Corrosion resistance for saltwater exposure

- Fire resistance for safety compliance

- Low smoke and halogen-free materials

- Reliable performance in extreme conditions

Telecommunications Infrastructure

EMC cables in telecommunications must:

- Maintain signal integrity over long distances

- Prevent crosstalk between adjacent circuits

- Meet stringent regulatory requirements

- Provide consistent performance across temperature ranges

EMC Cable Installation Best Practices

Proper Grounding Techniques

To be effective, the shielding should be bonded over 360°. For computer equipment and digital links, the shielding should be connected at each end of the cable. Connection of the shielding is very important for EMC.

Effective grounding requires:

- 360-degree shield termination at connection points

- Low-impedance ground paths

- Proper cable gland selection and installation

- Consistent grounding practices throughout the system

Cable Routing Considerations

Proper cable routing enhances EMC performance:

Separation from Interference Sources: Maintain adequate distance from power cables, motors, and switching equipment.

Avoid Loop Formation: Route cables to minimize the enclosed area that could act as an antenna for electromagnetic interference.

Use Dedicated Cable Trays: Separate EMC cables from potential interference sources using dedicated routing paths.

Shield Continuity: Ensure shield integrity throughout the cable run, including at junction boxes and connection points.

EMC Standards and Compliance

International Standards Framework

EMC cables must comply with various international standards:

IEC 61000 Series: Comprehensive electromagnetic compatibility standards covering emissions and immunity requirements.

EN 50147: European standards for railway applications requiring specific EMC performance.

DO-160: Aviation industry standard for electronic equipment including cable requirements.

MIL-STD-461: Military standard for EMC requirements in defense applications.

Testing and Certification

EMC cable testing typically includes:

- Screening effectiveness measurements

- Transfer impedance testing

- Coupling attenuation verification

- Environmental performance validation

Cable Length Considerations in EMC Design

Many EMC standards refer to cable length to decide how a product should be tested. Is it less than 3 meters or will it run around the factory floor and out through the wall? The length, type and function of product cabling directly dictates the test coupling mechanism an EMC lab will use.

Length considerations include:

- Short cables (under 3 meters) for localized applications

- Long runs requiring additional EMC measures

- Resonance effects at specific frequencies

- Signal degradation over distance

Advanced EMC Cable Technologies

Multi-Layer Shielding Systems

Modern EMC cables often incorporate multiple shielding layers:

- Inner foil for complete coverage

- Braided shield for mechanical protection

- Outer jacket for environmental protection

- Drain wires for improved grounding

Flexible Braided Solutions

Flexible braids absorb elongation and shortening due to heat. These designs accommodate:

- Dynamic applications with cable movement

- Temperature cycling in industrial environments

- Vibration resistance in mobile applications

- Long-term reliability in challenging conditions

Selecting the Right EMC Cable

Application Assessment

Consider these factors when selecting EMC cables:

Environmental Conditions: Temperature range, chemical exposure, moisture levels, and UV exposure requirements.

Mechanical Requirements: Flexibility needs, bend radius limitations, tensile strength, and crush resistance.

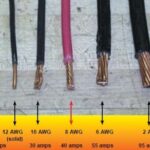

Electrical Specifications: Voltage rating, current capacity, impedance matching, and frequency response.

EMC Performance: Required shielding effectiveness, coupling resistance, and screening attenuation specifications.

Cost-Benefit Analysis

EMC cable selection involves balancing:

- Initial cable cost versus system protection value

- Installation complexity and labor costs

- Long-term reliability and maintenance requirements

- Regulatory compliance and certification costs

Installation and Maintenance

Professional Installation Requirements

Proper EMC cable installation requires:

- Trained technicians familiar with EMC principles

- Appropriate tools for shield termination

- Testing equipment to verify performance

- Documentation of installation practices

Ongoing Maintenance

Regular maintenance should include:

- Visual inspection of cable integrity

- Shield continuity testing

- Performance verification in critical applications

- Environmental monitoring for degradation factors

Troubleshooting EMC Issues

Common EMC Problems

Typical issues include:

- Inadequate shield termination

- Shield discontinuity at connections

- Improper cable routing

- Ground loop formation

Diagnostic Approaches

EMC troubleshooting involves:

- Systematic signal integrity testing

- Electromagnetic field measurements

- Shield effectiveness verification

- Ground impedance testing

Future Developments in EMC Cable Technology

Emerging Technologies

The EMC cable industry continues evolving with:

- Advanced composite shielding materials

- Smart cables with integrated monitoring

- Nanotechnology-enhanced conductors

- Environmentally sustainable materials

Industry 4.0 Integration

Modern manufacturing requires EMC cables that support:

- Industrial Internet of Things (IIoT) connectivity

- High-speed data transmission

- Predictive maintenance capabilities

- Integration with smart factory systems

Economic Considerations

Total Cost of Ownership

EMC cable investment should consider:

- Prevention of costly EMI-related failures

- Reduced downtime from interference issues

- Regulatory compliance cost avoidance

- Enhanced system reliability and performance

Return on Investment

Quality EMC cables provide value through:

- Improved system uptime and reliability

- Reduced troubleshooting and maintenance costs

- Enhanced product performance and quality

- Protection of valuable electronic equipment

Conclusion

EMC cables represent a critical component in modern electronic systems, providing essential protection against electromagnetic interference while ensuring regulatory compliance. Their sophisticated shielding designs, diverse material options, and specialized construction techniques make them indispensable for applications ranging from industrial automation to aerospace systems.

The selection and implementation of appropriate EMC cables requires careful consideration of environmental conditions, performance requirements, and installation practices. By understanding the principles of electromagnetic compatibility and following established best practices, engineers can ensure reliable system operation in increasingly complex electromagnetic environments.

As technology continues to advance and electromagnetic environments become more challenging, EMC cables will remain essential for maintaining signal integrity, protecting sensitive electronics, and ensuring compliance with evolving regulatory standards. Investment in quality EMC cables and proper installation practices provides long-term value through enhanced system reliability, reduced maintenance costs, and protection of critical electronic assets.

The future of EMC cable technology promises continued innovation in materials, design, and integration capabilities, supporting the evolving needs of modern electronic systems while maintaining the fundamental goal of electromagnetic compatibility.