The 6 AWG Peachbell All Aluminum Stranded Conductor (AAC) is a cost-effective, lightweight, and highly efficient solution designed for various low and medium voltage overhead power transmission and distribution applications. Composed entirely of aluminum, this conductor boasts excellent electrical conductivity and inherent corrosion resistance, making it a reliable choice for diverse environments, including those prone to harsh conditions.

Applications:

The AAC Peachbell conductor is versatile and ideal for a wide range of low and medium voltage overhead lines, especially where mechanical strength is not the primary limiting factor for the conductor itself:

- Urban Overhead Lines: Commonly deployed in urban areas, it efficiently carries significant voltages over shorter distances, supporting the robust power grids of cities and towns.

- Coastal Areas: Its long-lasting and corrosion-resistant properties make it an excellent choice for installations in humid, salty coastal environments where other materials might quickly deteriorate.

- Railway and Subway Industries: Benefits from the conductor's durability and resistance to environmental factors typically encountered in railway and subway systems, ensuring reliable operation.

- Shipyards and Offshore Construction Sites: Perfectly suited for providing power in demanding marine environments where durability and resistance to corrosion are paramount.

- Primary and Secondary Distribution: Serves as a dependable conductor for both primary and secondary power distribution applications, ensuring consistent supply to end-users.

Standards:

Our AAC Peachbell Conductor is manufactured and rigorously tested in strict accordance with the following industry standards, guaranteeing high quality and performance:

- ASTM B-230: Aluminum 1350-H19 wire for electrical purposes.

- ASTM B-231: Concentric Lay Stranded Aluminum 1350 Conductors.

Construction:

The AAC Peachbell Conductor features a precise construction designed for optimal performance:

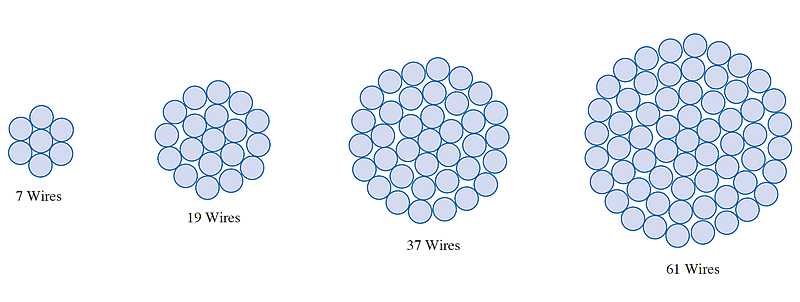

- Conductor: Composed of Aluminum alloy 1350 wires that are concentrically lay-stranded. The wires are helically wrapped around a central wire, forming a compact and efficient conductor.

- Stranding: Each successive layer in the stranding process has six more wires than the previous underlying layer, creating a uniform and stable cable.

- Lay Direction: The outer layer is laid in a right-hand direction, with the lay direction reversed in successive layers, contributing to the conductor's structural integrity and preventing unraveling.

All Aluminum Conductor AAC Construction