The AAC conductor, also known as aluminum stranded conductor, is a bare overhead conductor used in power transmission. It is specifically designed for applications in urban areas with short spans and where high conductivity is a key requirement. Its excellent corrosion resistance also makes it a suitable choice for coastal regions.

Key Specifications & Construction

- Standard: IEC 61089 (Round wire concentric lay overhead electrical stranded conductors).

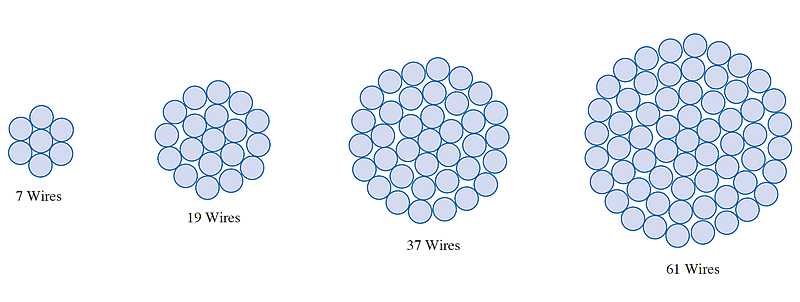

- Conductor Material: The conductors are made from concentrically stranded wires of electrolytically refined aluminum, with a minimum purity of 99.7% and a hard-drawn 1350 aluminum alloy.

- Conductor Shape: Available in circular and sectional shapes.

- Cross-Sectional Area: The standard covers a wide range of sizes, from mm² to mm².

- Insulation: None; this is a bare conductor.

Application

AAC conductors are widely used for overhead power lines in low, medium, and high voltage applications. They are a common sight in urban environments and are favored for their high conductivity and corrosion resistance. While they can be connected to copper conductors, it is often preferred to use aluminum conductors for service connections to maintain a consistent material system.

Parameter Table

*Note: The current rating values are based on a wind velocity of 0.6 m/s, solar radiation of 1200 W/m², an ambient temperature of C, and a conductor temperature of C.