All Aluminum Alloy Conductors (AAAC), manufactured in strict adherence to DIN 48201, are highly efficient and reliable bare conductors primarily used in overhead power transmission and distribution lines. These conductors are made from high-strength aluminum-magnesium-silicon alloys, offering superior mechanical and electrical properties compared to traditional aluminum conductors (AAC) and a favorable alternative to Aluminum Conductor Steel Reinforced (ACSR) conductors in specific applications.

Key Features

- Shape of Conductor: Stranded circular construction ensures optimal mechanical flexibility and consistent electrical performance.

- Sectional Area Range: Available in a wide range of sizes from 16 mm² to 1000 mm², catering to diverse power transmission requirements.

- Insulation: N/A (Bare Conductor) – designed for overhead applications where air acts as the primary insulation.

- High Strength-to-Weight Ratio: The aluminum alloy composition provides excellent mechanical strength with a relatively low weight, allowing for longer spans and reduced structural loads on towers.

- Superior Corrosion Resistance: Inherently resistant to corrosion, particularly beneficial in coastal or polluted environments, reducing maintenance and extending service life.

- Good Electrical Conductivity: Offers efficient power transmission with minimal losses.

- Improved Sag Characteristics: Exhibits favorable sag performance under various loading conditions, contributing to stable overhead line design.

- Durability and Longevity: The robust alloy construction ensures a long service life with high reliability.

Application

AAAC conductors conforming to DIN 48201 are primarily utilized as bare overhead conductors in:

- Overhead Power Transmission Lines: For high and medium voltage transmission, particularly where light weight and high strength are advantageous.

- Overhead Power Distribution Networks: Ideal for primary and secondary distribution lines in both urban and rural settings.

- Coastal and Industrial Areas: Preferred in environments with high salinity or pollution due to their excellent corrosion resistance.

- Areas Requiring Longer Spans: Their superior mechanical properties enable longer distances between support structures, reducing infrastructure costs.

Standard

Our AAAC - All Aluminum Alloy Conductors are meticulously manufactured and tested to comply with:

- DIN 48201: This German industrial standard specifies the requirements for bare aluminum alloy stranded conductors for overhead lines.

Construction

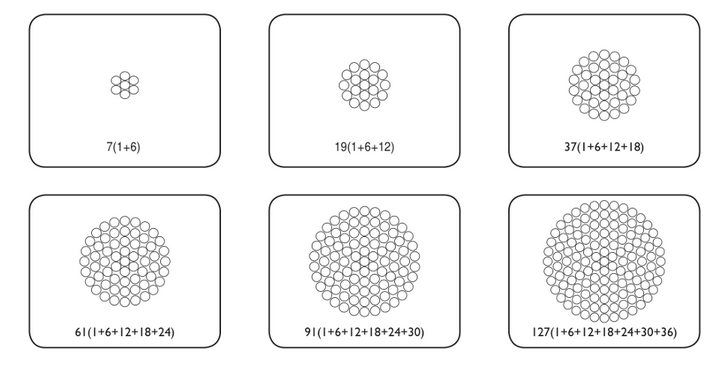

AAAC conductors are formed by concentrically stranding wires made from aluminum-magnesium-silicon alloy. The specific number of wires and their arrangement depend on the nominal sectional area, ensuring the conductor meets the mechanical and electrical performance criteria outlined in DIN 48201. The stranded circular shape optimizes both handling during installation and aerodynamic performance in service.

Quality and Certification

We are committed to delivering high-quality AAAC conductors that meet rigorous industry standards. Our manufacturing processes and products are often supported by certifications such as:

- ISO9001: Quality Management System

- CCC: China Compulsory Certificate

- Other relevant international certifications (e.g., SGS, BV), ensuring adherence to global quality and safety benchmarks.

Advantages

Choosing our AAAC - All Aluminum Alloy Conductors to DIN 48201 standard offers several key advantages:

- High Quality: Guaranteed manufacturing to strict DIN standards.

- Competitive Price: Providing a cost-effective solution for overhead line projects.

- Excellent Service: Dedicated customer support from inquiry through to delivery.

- Reliable Performance: Engineered for long-term stability and minimal maintenance.

For detailed technical specifications, specific sectional area requirements, or to request a quote, please contact us.