AAAC-All Aluminum Alloy Conductors IS 398 PART 4 Application

Used as bare overhead conductor for primary and secondary distribution. Designed for utilizing a high-strength aluminum-alloy to achieve a high strength-to-weight ratio; affords good sag characteristics.

(1)AAAC conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.

(2)The aluminum alloy conductors are used in replace of single-layer ACSR conductors to reduce power loss in overhead distribution and transmission lines,when replacing the aluminum conductor steel reinforced , the AAAC can save 5-8% of the construction cost.

(3)AAAC referred to have higher strength but lower conductivity than pure aluminum. Being lighter, alloy conductors can sometimes be used to replace the conventional ACSR.

Standards:

IS 398 PART 4 Standard

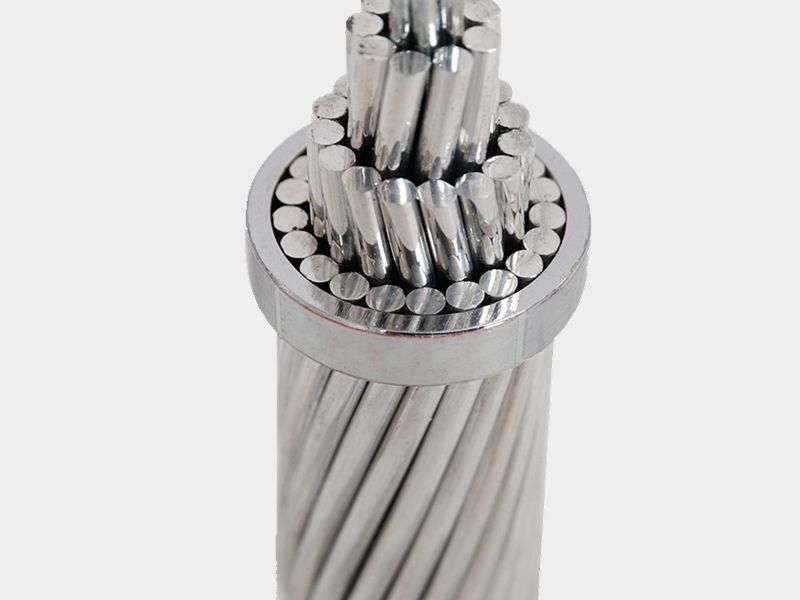

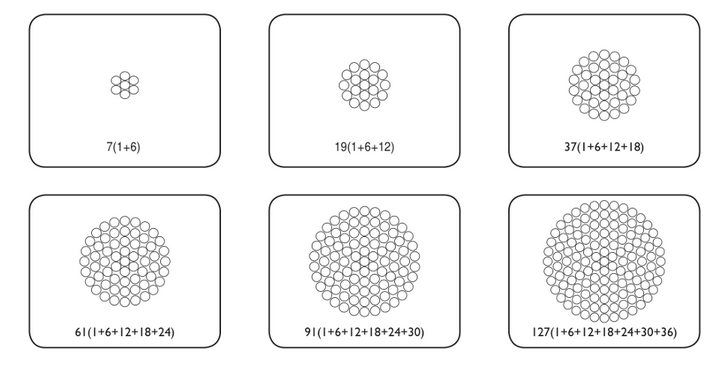

Construction

All Aluminum Alloy construction