ACAR (Aluminum Conductor Alloy Reinforced) is a high-performance overhead conductor designed for power transmission and distribution lines. It combines the high conductivity of Aluminum 1350 with the superior mechanical strength of an Aluminum-Magnesium-Silicon alloy (AlMgSi) core, resulting in an excellent strength-to-weight ratio—often superior to traditional ACSR conductors.

ACAR is ideal for installations where reduced line sag, high current carrying capacity, and improved mechanical performance are critical.

Key Features

High strength-to-weight ratio compared to ACSR

Better corrosion resistance due to all-aluminum construction

Reduced line sag under load and temperature stress

Suitable for long-span and high-load applications

Excellent conductivity and mechanical strength

Complies with ASTM B524 standard for concentric-lay-stranded ACAR

Applications

ACAR conductors are widely used as bare overhead transmission and distribution lines, particularly in:

Long-span transmission lines

Coastal and corrosive environments

Heavily loaded conductors requiring low sag

Power grid upgrades or capacity expansions

Replacement for ACSR in harsh environments

Construction

ACAR Conductor construction

| Component | Description |

|---|---|

| Core | Central strand or strands of high-strength aluminum alloy (AlMgSi) |

| Outer Layers | One or more concentric layers of hard-drawn Aluminum 1350 wires |

| Stranding | Concentric-lay stranding; in some designs, alloy strands may be distributed throughout |

All wires—both aluminum and alloy—are of equal diameter, and stranding combinations may vary based on mechanical and electrical performance requirements.

Standard

ASTM B524 – Standard Specification for Concentric-Lay-Stranded Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR)

Other applicable: ASTM B398 (AlMgSi alloy wires), ASTM B232 (Aluminum wires)

Advantages Over ACSR

| Feature | ACAR | ACSR |

|---|---|---|

| Corrosion Resistance | Higher (all-aluminum) | Lower (steel core) |

| Weight | Lighter | Heavier |

| Sag Performance | Better | Moderate |

| Strength-to-Weight | Superior | Lower |

| Thermal Expansion | Lower | Higher |

| Magnetic Properties | Non-magnetic | Magnetic (steel) |

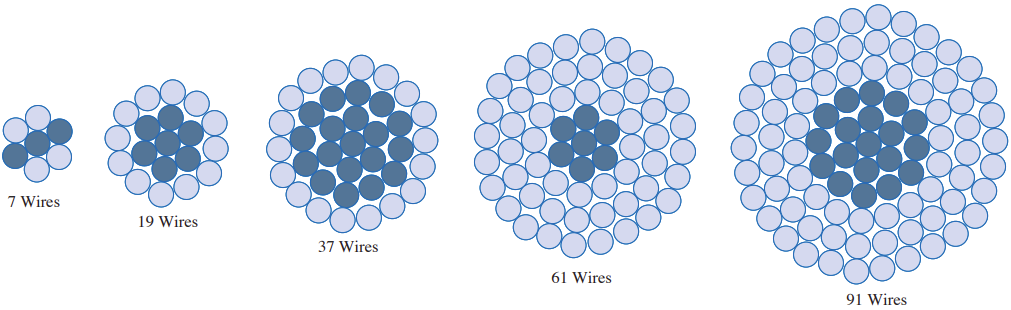

Available Configurations

ACAR conductors are available in multiple strand designs (e.g., 18/19, 26/7, 30/7, 48/7) based on application requirements. TOT Wire & Cable supplies ACAR in a wide range of sizes and constructions per ASTM B524.

Technical Specifications (Sample)

| Parameter | Value |

|---|---|

| Standard | ASTM B524 |

| Rated Voltage | Up to 500 kV |

| Conductor Material | Aluminum 1350 + AlMgSi alloy |

| Stranding | Concentric lay, multi-strand |

| Temperature Rating | Up to 90°C (continuous), 150°C (emergency) |

| Tensile Strength | Customizable based on alloy core design |

| Corrosion Resistance | Excellent (no galvanic reaction with aluminum components) |

Why Choose TOT ACAR Conductors?

Strict ASTM compliance (B524, B398, etc.)

Custom design available for optimized performance

Ideal for utility upgrades and transmission expansion

Fast delivery and competitive pricing

Contact Us

Need help selecting the right ACAR conductor size or stranding configuration? Contact TOT Wire & Cable for expert advice, technical datasheets, and competitive pricing tailored to your project needs.