ACAR (Aluminum Conductor Alloy Reinforced) conductors, manufactured in full compliance with IEC 61089, represent a sophisticated solution for overhead power transmission and distribution lines. These conductors ingeniously combine a high-strength aluminum alloy core with layers of conductive aluminum wires, delivering an optimal balance of robust mechanical strength and excellent electrical conductivity. The 'A1/A2' designation within this standard refers to the specific types of high-performance aluminum alloys used, tailored to meet demanding application requirements.

Key Aspects and Features of ACAR Conductors (IEC 61089)

Construction: ACAR conductors feature a unique composite design:

- A central core is made from a high-strength aluminum alloy (commonly 6201-T81). This alloy core provides the necessary mechanical integrity and tensile strength.

- One or more layers of high-purity aluminum wires (typically 1350-H19) are concentrically stranded around the alloy core. These outer layers ensure excellent electrical conductivity.

Materials (A1/A2 Designation): The 'A1/A2' in the context of IEC 61089 specifically refers to the types of aluminum alloys used:

- A1: Typically denotes aluminum alloy 6201, known for its superior mechanical properties.

- A2: Refers to a different type of aluminum alloy or a specific temper of aluminum, providing varied mechanical and electrical characteristics to suit particular application demands. This allows for customization based on strength, conductivity, and sag requirements.

Advantages:

- Good Strength-to-Weight Ratio: The combination of alloy core and aluminum strands results in a conductor that is strong enough for long spans and demanding conditions, yet light enough to reduce structural load on towers.

- Higher Ampacity: Compared to conductors of similar weight, ACAR often provides a higher current carrying capacity (ampacity), making it more efficient for power transmission.

- Balanced Properties: Offers an excellent equilibrium between mechanical strength and electrical conductivity, leading to reliable and efficient power delivery.

- Corrosion Resistance: Aluminum alloys inherently possess good corrosion resistance, contributing to the conductor's longevity in various environments.

Applications: ACAR conductors are a popular choice for a wide array of overhead power line applications:

- Power Transmission Lines: Used in both high-voltage and medium-voltage networks.

- Power Distribution Lines: Essential for reliable power delivery to communities and industries.

- Long-Span Crossings: Particularly suitable for challenging terrains such as river crossings, valleys, or other areas requiring extended distances between support structures, due to their impressive strength and sag characteristics.

IEC 61089 Standard Compliance: This crucial international standard specifies the requirements for round wire concentric lay overhead electrical stranded conductors, of which ACAR conductors are a key type. Adherence to IEC 61089 ensures that our ACAR conductors meet global benchmarks for design, materials, construction, testing, and performance.

Construction

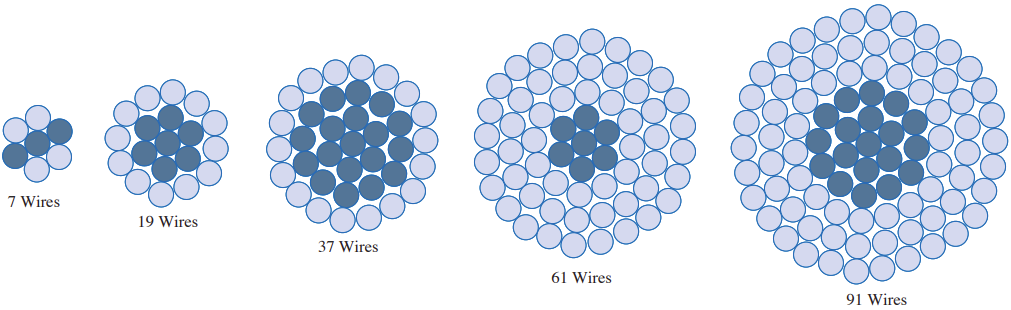

Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR) is a concentric-lay-stranded conductor consisting of stranded aluminum alloy central core with one or more layers of hard drawn stranded aluminum wires. The diameters of all wires are the same. Aluminum and aluminum-alloy wires can be mixed in the same layer.

ACAR Conductor construction

ACAR conductors, especially those meticulously manufactured to IEC 61089 standards (A1/A2 Conductors), are a premier choice for modern overhead power line infrastructure. Their carefully balanced mechanical and electrical properties, combined with their ability to perform reliably under various environmental conditions, make them an efficient, durable, and cost-effective solution for utilities worldwide.

For detailed technical specifications, custom configurations, or to discuss how our IEC 61089 compliant ACAR conductors can meet your project requirements, please contact our sales team.