ACAR (Aluminum Conductor Alloy Reinforced) conductors, meticulously engineered to comply with IEC 61089, represent a sophisticated and highly efficient solution for overhead power transmission and distribution lines. This advanced conductor type uniquely combines the robust mechanical strength of an aluminum alloy core with the excellent electrical conductivity of aluminum wires. The designation 'A1/A3' within this standard refers to the specific types of aluminum and aluminum alloy materials utilized, optimized to deliver a superior balance of performance for diverse overhead line applications.

Key Features of ACAR Conductors (IEC 61089 - A1/A3)

Construction: ACAR conductors are designed with a composite structure to maximize both electrical and mechanical properties:

- A central core is made from a high-strength aluminum alloy, typically 6201-T81. This alloy core provides the conductor's primary tensile strength and mechanical resilience.

- Surrounding the alloy core are one or more concentric layers of hard-drawn aluminum wires, commonly 1350-H19. These outer aluminum strands ensure excellent electrical conductivity.

Material Standards (A1/A3 Designation): The 'A1/A3' nomenclature specifically identifies the material types and their respective standards:

- A1 Conductors: Refer to the hard-drawn aluminum wires (typically 1350-H19) used in the outer layers, which are specified in IEC 60889. These wires are known for their high conductivity.

- A3 Conductors: Refer to the aluminum alloy core, often 6201-T81, which is specified in IEC 60104. This alloy provides the high mechanical strength. This precise combination is what defines the ACAR A1/A3 construction.

Advantages:

- Optimized Strength-to-Weight Ratio: ACAR conductors offer a superior strength-to-weight ratio compared to many other conductor types, including ACSR. This allows for longer spans between support structures, reducing overall infrastructure costs.

- Higher Current Capacity (Ampacity): For a given weight, ACAR conductors can often carry a higher current (ampacity) than ACSR conductors, leading to more efficient power transmission.

- Balanced Performance: They provide an excellent equilibrium between high mechanical strength and efficient electrical conductivity, ensuring reliable and stable power delivery.

- Good Corrosion Resistance: Both aluminum and aluminum alloys inherently offer good resistance to corrosion, contributing to the conductor's longevity in various environmental conditions.

Applications: ACAR conductors are extensively utilized in overhead power transmission and distribution lines, particularly suitable for:

- Long-Span Applications: Where robust mechanical strength is required to bridge significant distances between towers.

- Regions with High Wind or Ice Loading: Capable of withstanding substantial environmental stresses.

- High-Efficiency Transmission: Offering improved current carrying capacity for efficient power transfer.

- Both High-Voltage (HV) and Medium-Voltage (MV) Lines: Providing reliable performance across different voltage levels.

Standard Compliance: Our ACAR conductors are manufactured and tested in strict adherence to IEC 61089. This international standard governs the construction and testing of round wire concentric lay overhead electrical stranded conductors, ensuring that our products meet global benchmarks for quality, safety, and performance.

Construction

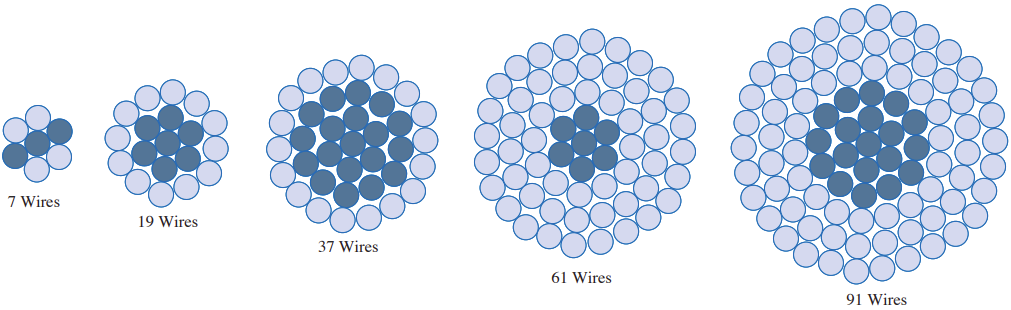

Aluminum Conductors, Aluminum-Alloy Reinforced (ACAR) is a concentric-lay-stranded conductor consisting of stranded aluminum alloy central core with one or more layers of hard drawn stranded aluminum wires. The diameters of all wires are the same. Aluminum and aluminum-alloy wires can be mixed in the same layer.

ACAR Conductor construction

ACAR A1/A3 conductors, engineered to meet the exacting specifications of IEC 61089, represent a cutting-edge solution for overhead power infrastructure. By skillfully combining the properties of high-conductivity aluminum (A1) and high-strength aluminum alloy (A3), these conductors achieve an optimal balance of mechanical integrity and electrical efficiency. This makes them a preferred choice for utilities seeking durable, high-capacity, and cost-effective solutions for power transmission and distribution across diverse geographical and environmental conditions.

For detailed technical specifications, custom configurations, or to discuss how our IEC 61089 compliant ACAR A1/A3 conductors can meet your project requirements, please contact our sales team.