ACS (Aluminum Clad Steel Wire), also known as Alumoweld wire, is a bimetallic conductor that combines the high tensile strength of steel with the superior conductivity and corrosion resistance of aluminum. Manufactured in accordance with IEC 61232 international standard, ACS wire is widely used in overhead transmission systems, especially in environments where durability and corrosion resistance are critical.

Applications

ACS wire is suitable for a broad range of overhead line and utility applications, including:

Core wire for ACSR/AW (Aluminum Conductor Steel Reinforced with Aluminum Clad Steel Core)

Overhead ground wire (OHGW)

Extra high voltage overhead conductors

OPGW (Optical Ground Wire)

Messenger wire and guy wire

Self-damping conductor lines

Fencing, grounding systems, and even barbed wire

Ideal for coastal, island, humid, salt-fog, and industrially polluted regions

Standards

Manufactured to meet or exceed the following standards:

IEC 61232 – International standard for aluminum-clad steel wires for overhead lines

ASTM B416 / B415 / B502

DIN 48201

AS 1222.2

Other regional or customer-specific standards on request

Features

Corrosion Resistance: Aluminum cladding offers excellent resistance to atmospheric and chemical corrosion, far superior to galvanized steel.

High Strength: The steel core provides superior tensile strength, suitable for long spans and high tension installations.

Thermal Stability: Maintains structural integrity at elevated operating temperatures.

Excellent Bonding: Metallurgically bonded aluminum layer will not flake or separate, even under mechanical stress or thermal cycling.

Lightweight with High Conductivity: Offers an excellent balance between electrical performance and mechanical durability.

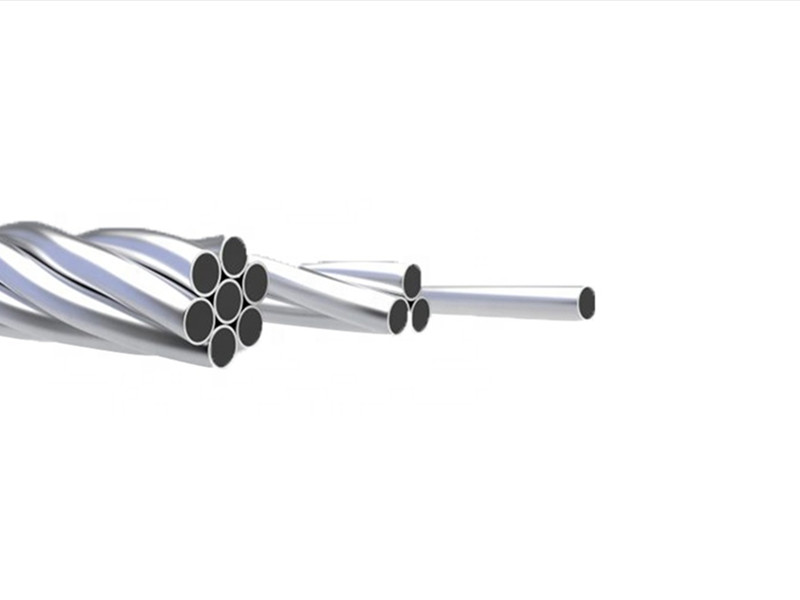

Construction

Core: High-tensile galvanized steel

Cladding: Aluminum layer bonded to the steel core through a metallurgical process

Aluminum Content: Typically ~25% of total cross-sectional area (other ratios available on request)

Finish: Smooth surface, bright finish, optional lubrication or anti-corrosive treatment available