Stranded hard drawn copper conductors are engineered for overhead transmission and distribution systems where high mechanical strength, durability, and conductivity are essential. These conductors are composed of multiple hard drawn copper wires stranded in concentric layers, making them ideal for long-span aerial installations, especially in demanding environments.

Standard

Bare stranded hard-drawn copper conductor can be supplied to meet various International Standards as follows:

BS 7884

DIN 48201 / 1

However, Hongda Cables can also supply a range of alternative designs to meet customer-specified requirements.

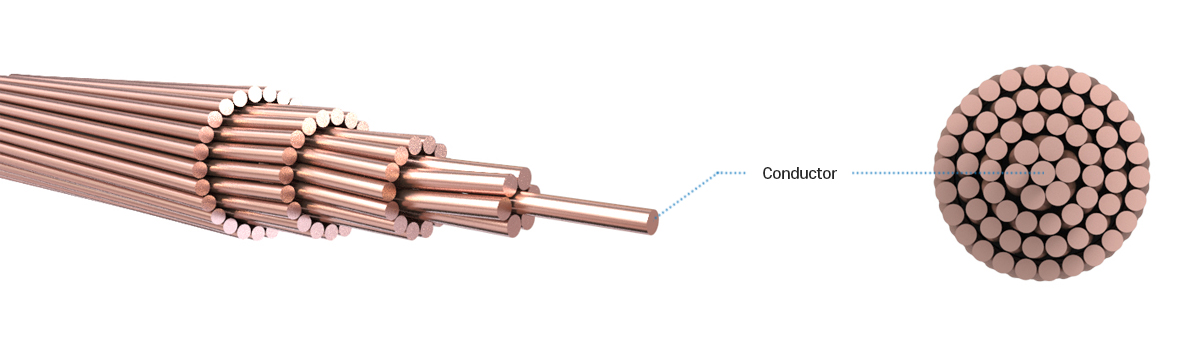

Construction

Conductor Material: Hard drawn copper

Structure: Concentric-lay-stranded construction (e.g., 7, 19, or more wires)

Temper: Hard drawn (non-annealed), offering superior tensile strength compared to annealed copper

Available Sizes: In accordance with applicable standards (BS, DIN, ASTM)

Hard-drawn copper stranded wire Conductor

Key Features

High Tensile Strength

Hard drawn copper offers excellent resistance to mechanical stress, sagging, and breakage—ideal for long-span and overhead applications.Stranded Flexibility

The concentric stranded design increases flexibility, making installation easier and improving resistance to vibration and bending stress.Good Electrical Conductivity

While slightly lower than annealed copper, hard drawn copper still provides efficient power transmission for medium to high-voltage systems.Corrosion Resistance

Bare copper provides natural resistance to corrosion, extending service life in outdoor and urban environments.Low Maintenance

Suitable for applications where long-term durability and minimal maintenance are required.

Applications

Overhead power transmission and distribution lines

Bus lines in power stations

Railway electrification systems (where applicable)

Infrastructure requiring robust aerial copper conductors

Advantages at a Glance

| Feature | Benefit |

|---|---|

| Stranded Construction | Improved flexibility and ease of installation |

| Hard Drawn Copper | Enhanced tensile strength for long-span and overhead tension |

| Standard-Compliant | Compatible with international utility and infrastructure requirements |

| Durable Design | Resists fatigue, vibration, and mechanical stress |

For technical specifications, datasheets, or quotation requests, feel free to contact our sales team.