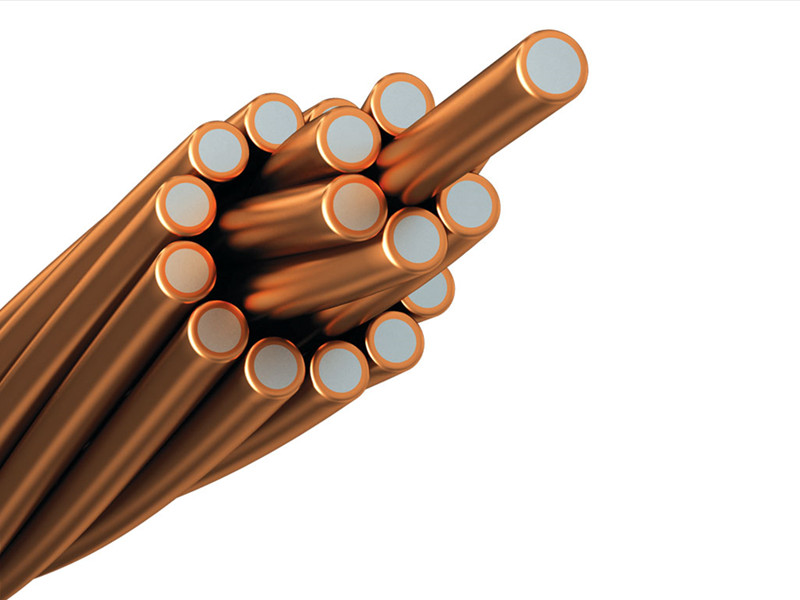

Copper Clad Steel (CCS) conductors combine the high conductivity of copper with the high tensile strength and durability of steel, offering a reliable solution for grounding, overhead support, and anti-theft applications. Manufactured to meet multiple ASTM standards, CCS wire is engineered for performance in harsh electrical and environmental conditions.

Applications

CCS wire and strand are widely used in:

Buried Ground Grid Systems

Overhead Ground Wire (Shield Wire)

Messenger Wire

Lightning Protection

Guy Wire and Structural Reinforcement

Antenna Wire and Transmission Lines

Its unique composition allows CCS conductors to withstand mechanical stress and electrical fault conditions, making them ideal for critical infrastructure.

Key Features

Dual-Metal Performance

The steel core provides excellent mechanical strength, while the outer copper layer offers stable conductivity and corrosion resistance.Theft Deterrent

With minimal scrap value and high cutting resistance, CCS wire helps reduce the risk of cable theft in vulnerable installations.Fault Current Performance

Capable of withstanding high short-circuit currents without significant degradation.Corrosion Resistance

The copper cladding protects the steel core from oxidation, ensuring long service life in harsh or underground environments.

Construction

Copper Clad Steel conductors are manufactured by bonding a continuous layer of high-purity copper onto a high-strength steel core using a metallurgical process. This ensures:

Excellent adhesion between copper and steel

Uniform conductivity along the surface

Flexibility and durability across temperature variations

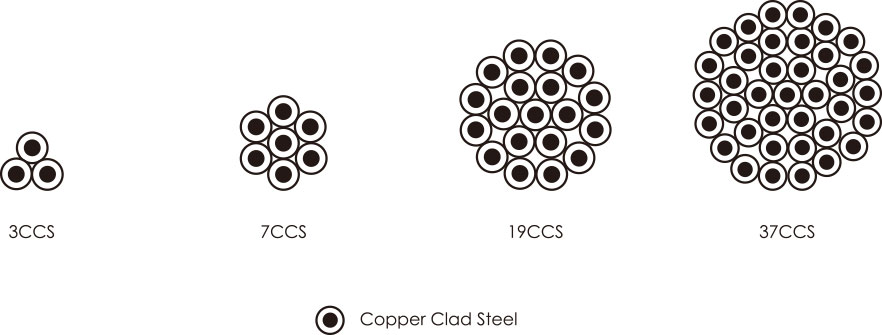

Available in solid or concentric-lay-stranded constructions, depending on application requirements.

Applicable Standards

ASTM B227 – Hard-Drawn Copperclad Steel Wire

ASTM B228 – Concentric-Lay-Stranded Copperclad Steel Conductors

ASTM B910 – Annealed Copperclad Steel Wire

ASTM B193 – Resistivity Testing for Electrical Conductors

ASTM B258 – AWG Size and Cross-Sectional Area Specifications

Benefits at a Glance

| Feature | Benefit |

|---|---|

| Copper-Clad Design | Combines conductivity and tensile strength |

| ASTM-Compliant | Ensures international quality and dimensional standards |

| Anti-Theft Properties | Low scrap value and cutting difficulty deter vandalism |

| Long Service Life | Resistant to corrosion and harsh environments |

| Versatile Construction | Available in solid or stranded designs for varied use |