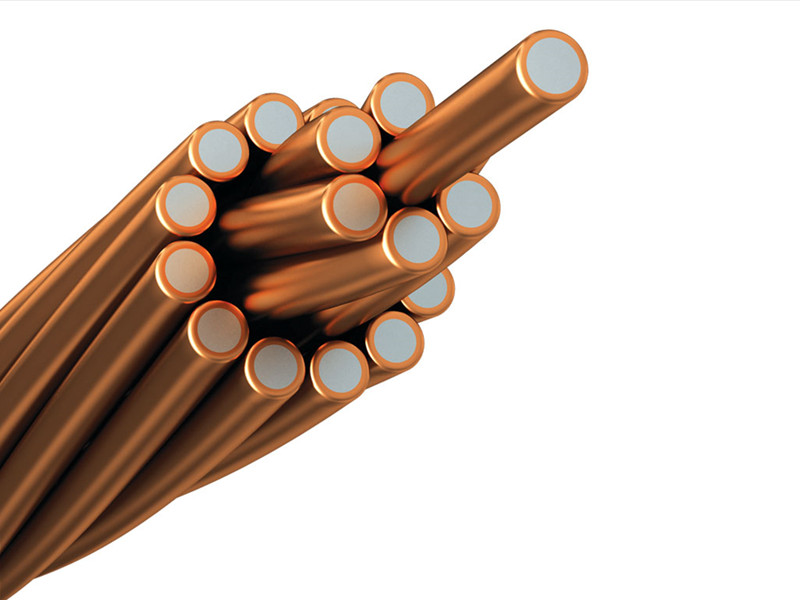

Copper Clad Steel (CCS) wire, manufactured to meet stringent IEC standards, represents an innovative conductor solution that synergizes the high electrical conductivity of copper with the superior mechanical strength of steel. This unique composite material is ideally suited for applications demanding both excellent electrical performance and robust structural integrity.

Key Features and Benefits

- Composite Construction: CCS wire is expertly engineered with a high-strength steel core that is meticulously bonded with a concentric layer of copper on its surface. This bimetallic design is central to its exceptional performance.

- Balanced Performance: It effectively combines the best attributes of both metals, offering high conductivity (attributable to the copper layer) and high tensile strength (derived from the steel core).

- Cost-Effective Alternative: In many applications where both conductivity and strength are critical, CCS wire provides a cost-effective alternative to using solid copper conductors, which may offer similar conductivity but lack the inherent strength of steel.

- Corrosion Resistance: The copper cladding provides enhanced corrosion resistance, protecting the steel core and extending the service life of the conductor in various environments.

- Durability: The robust nature of the steel core contributes to the overall durability and resistance to mechanical stress, making CCS wire a reliable choice for long-term installations.

Applications

The unique combination of properties in CCS wire makes it highly versatile and suitable for a diverse range of electrical and telecommunication applications, including:

- Overhead Power Transmission Lines: Used as messenger wires, ground wires, or phase conductors where strength is crucial for long spans and resistance to environmental forces.

- Earthing and Grounding Systems: Provides a strong, conductive, and corrosion-resistant solution for critical safety grounding in electrical installations and substations.

- Catenary Wires for Electrified Railways: Its high tensile strength is essential for supporting overhead contact lines in railway electrification systems.

- Coaxial Cables for Cable TV: The steel core provides necessary strength, while the copper cladding ensures excellent signal transmission in broadband communication.

- Telephone and Communication Lines: Used in various communication infrastructures where both mechanical support and reliable signal transfer are needed.

- Lightning Conductors: Offers a strong and conductive path for lightning currents, protecting structures and equipment.

Standards Compliance

While the core reference for this product is IEC (International Electrotechnical Commission) standards, CCS wire can also be manufactured to comply with other significant international specifications, such as ASTM.

- IEC Standards for CCS Wire: Although there isn't one single IEC standard exclusively dedicated to Copper Clad Steel wire, our CCS conductors are designed and produced to meet the relevant sections and performance criteria within the broader IEC framework for electrical and electronic products. This ensures compliance with international benchmarks for materials, performance, and safety relevant to the intended application of the CCS wire. When specifying IEC standards, it is crucial to refer to the particular section or related standard applicable to the specific use case of the CCS wire (e.g., within IEC 61089 for overhead conductors or relevant communication cable standards).

- ASTM B228: Standard Specification for Concentric-Lay-Stranded Copper-Clad Steel Conductors. This standard specifically covers copper-clad steel wire for electrical purposes, addressing its construction and properties.

- ASTM B452: Standard Specification for Copper-Clad Steel Wire Strand for Electrical Use. This standard focuses on the stranded form of copper-clad steel wire used in various electrical applications.

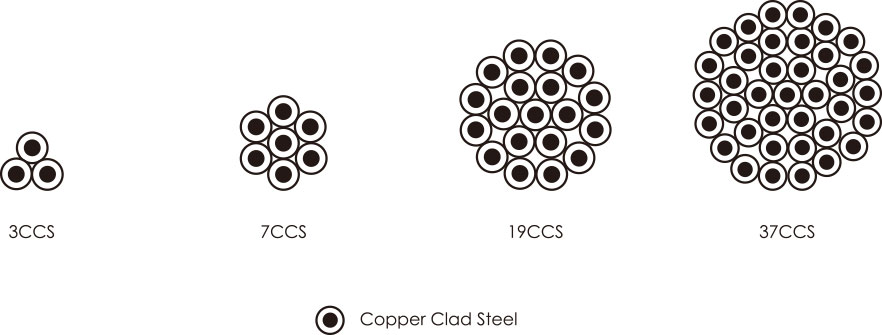

Construction

Copper Clad Steel Wire

Generally, the Copper Clad Steel conductor is formed by the following construction:

Copper Clad Steel Wire Construction

Copper Clad Steel (CCS) Conductor Wire, when engineered to meet rigorous IEC and other relevant standards, delivers a compelling solution for applications that demand both superior electrical conductivity and high mechanical strength. Its composite nature provides a robust and cost-effective alternative to pure copper, ensuring reliable performance and extended service life in demanding environments.

For detailed technical specifications, custom requirements, or to inquire about our IEC-compliant CCS wire solutions, please contact our sales team.