CVV Control Cable Application

For supervisory electrical equipment, station control circuits.Suitable for indoor and outdoor installation in wet or dry locations,in conduit, duct, trench and cable tray.

CVV Control Cable Standard

KS C IEC 60502-1

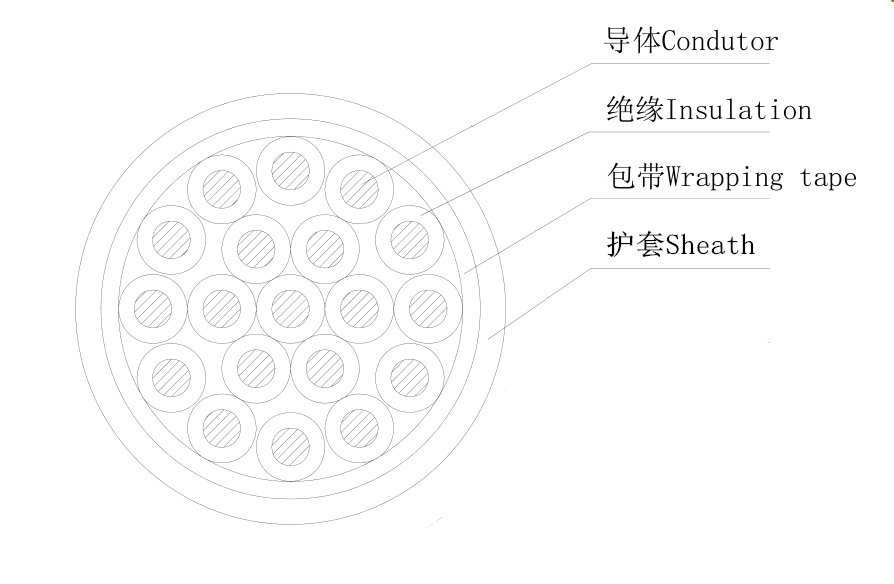

CVV Control Cable Construction

① Conductor: Annealed copper wire for electrical use

② Insulation: PVC or Flame retardant PVC

③ Binder: Polyester Tape

④ Sheath: PVC or Flame retardant PVC

CVV Control Cable Construction

Cable Type

| Symbol | MAX. Operating Temperature of Conductor (°C) |

Insulation Materials | Sheath Materials | Application |

| CVV | 60 | PVC | PVC | General use |

| CEV | 75 | Polyethylene | PVC | |

| CCV | 90 | Crosslinked Polyethylene |

PVC | |

| CEE | 75 | Polyethylene | Polyethylene (Black) | Chemical resistance |

| CCE | 90 | Crosslinked Polyethylene | Polyethylene (Black) |

Shield types and symbols

| Shield Type | Symbol | Remarks |

| Annealed copper tape | -S | Annealed copper tape is wrapped around cores. |

| Aluminum laminated plastic tape | -SLA | Applied for grounding through drain wire. |

| Annealed copper wire braid | -SB | Shield is formed by braided copper wire. |

| Annealed copper tape and steel tape | -SCF | Annealed copper tape and steel tape are wrapped around cores. |