KVV Control Cable Application

KVV PVC Insulated Cable belongs to the control cable in the cables for electrical installations. It has good high temperature resistance, cold resistance and aging resistance. It is generally used for control and monitoring circuits and protection circuits. In addition, flame-retardant, fire-resistant and low-smoke and halogen-free control cables can be produced according to user requirements. Different types of KVV cables have different characteristics and functions.

KVV Cable Standard

IEC 60227, IEC 60502, GB/T 9330, BS 6500

KVV Control Cable Types

| Model | Name | Main application |

| KVV | Copper conductor PVC insulated PVC sheathed control cable | For laying indoors, in trenches and in ducts, for fixed installation |

| KVVP | Copper conductor PVC insulated PVC sheathed copper braiding screened control cable | For laying indoors, in trenches and in dusts, for fixed installation |

| KVVP2 | Copper conductor PVC insulated and sheathed control cable with steel tape shield | For laying indoors, in trenches and in dusts and in ground, able

to withstand heavier mechanical force, for fixed installation |

| KVV22 | Copper conductor PVC insulated and sheathed control cable with steel tape armour | For laying indoors, in trenches and in dusts and in ground, able

to withstand heavier mechanical force, for fixed installation |

| KVVR | Copper conductor PVC insulated flexible control cable | For laying indoors, movable and flexible |

| ZR-KVVRP | Copper conductor PVC insulated PVC sheathed flame retardant flexible control cable with braided shield | Fixed laying indoors with capability of moving and screening |

| ZR-KVV | Copper conductor PVC insulated and sheathed flame retardant control cable | For laying indoors, in trenches, in ducts and for fixed installation,

the cable should be flame retardant |

| ZR-KVVP2 | Copper conductor PVC insulated and sheathed flame retardant control cable with steel tape shield | For laying indoors, in trenches, in ducts and for fixed installation,

the cable should be flame retardant |

| ZR-KVV22 | Copper conductor PVC insulated and sheathed flame retardant control cable with steel tape armour | For laying indoors, in trenches, in ducts and underground, the

cable should be flame-retardant and able to bear beavier external mechanical force, and for fixed installation |

| ZR-KVVR | Copper conductor PVC insulated and sheathed flame retardant flexible control cable | For laying indoors, and the cable should be flexible and movablea |

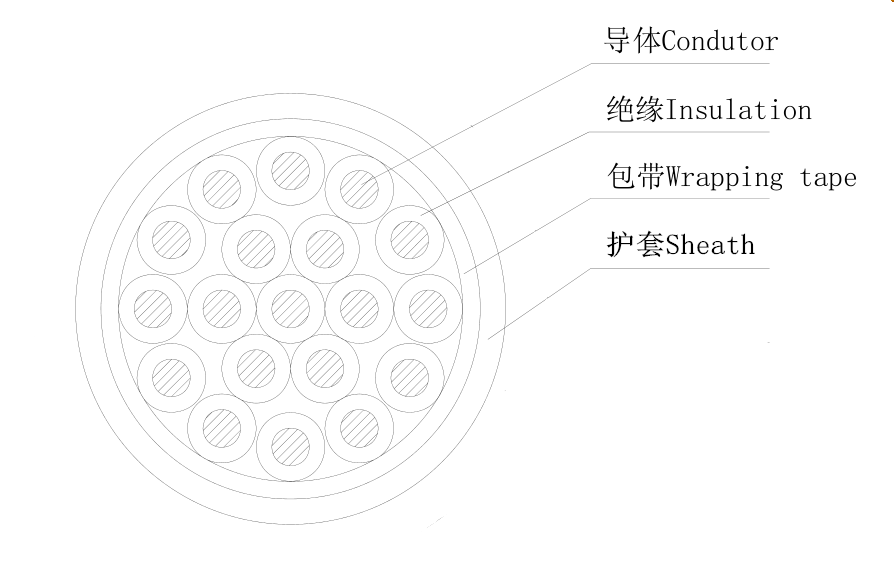

KVV Control Cable Construction