Cable H07Z-R Application

In pipes or ducts and internal wiring of appliances with maximum operating temperatures of 90°C, and generally in areas (such as public and government buildings) where smoke and toxic fumes may cause a threat to life and equipment. The cables produce no corrosive gases when burnt which is particularly important where electronic equipment is installed.

Cable H07Z-R Standards:

HD 22.9 S2, VDE-0282 Part-9, BS 7211, IEC 60754-2, EN 50267, VDE 0482-267,

CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant

CONSTRUCTION :

Cable H07Z-R Construction

Cable H07Z-R Construction

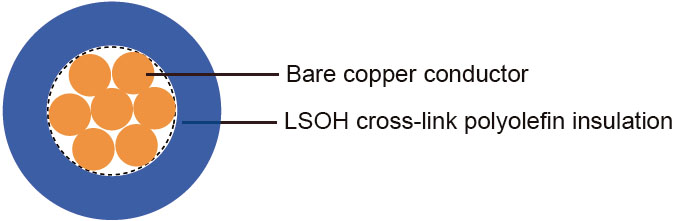

- Fine bare copper strands

- Strands to VDE-0295 Class-2, IEC 60228

- Insulation

- Cross-link polyolefin EI5 core insulation

- LSOH- low smoke, zero halogen,Type EI5 thermosetting insulation according to BS EN 50363-5.

TECHNICAL :

Cable H07Z-R Technical Data

- Working voltage: 450/750

- Test voltage: 2500 volts

- Flexing bending radius: 8 x Ø

- Static bending radius: 8 x Ø

- Flexing temperature: -15º C to +90º C

- Static temperature: -40º C to +90º C

- Flame retardant: IEC 60332.1

- Insulation resistance: 10 M x km

- Smoke density acc. to EN 50268 / IEC 61034

- Corrosiveness of combustion gases acc. to EN 50267-2-2, IEC 60754-2

- Flame test: flame-retardant acc. to EN 50265-2-1, IEC 60332.1