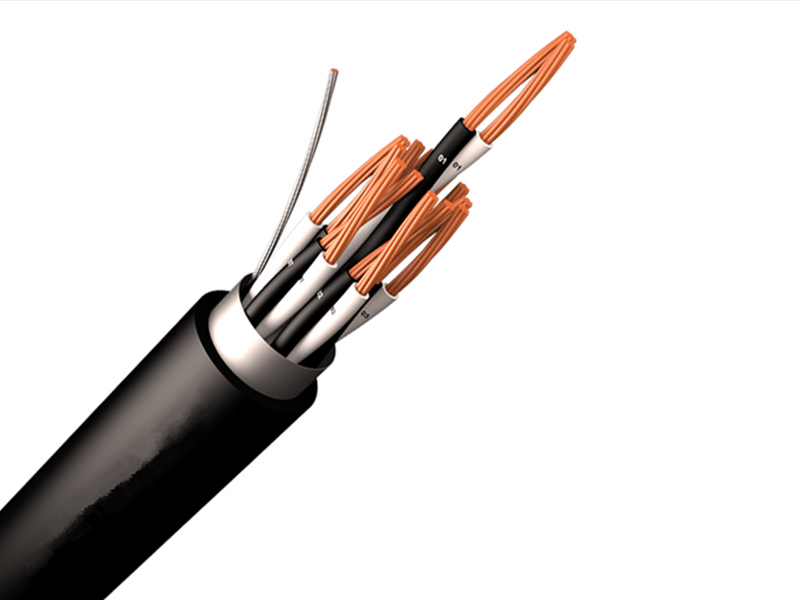

Instrumentation Cable XLPE-OS-LSOH BS5308 Cable Part 1 Type1 Application:

Instrumentation cables are commonly used to transmit analogue or digital signals in measurement and process control for electrical equipment and station control circuits in public networks and industrial plants. These lines provide good mechanical protection for industrial applications.

Instrumentation Cable XLPE-OS-LSOH BS5308 Cable Part 1 Type1 Standard:

Cable design: BS 5308 BS EN 50288-7

Conductor: IEC 60228

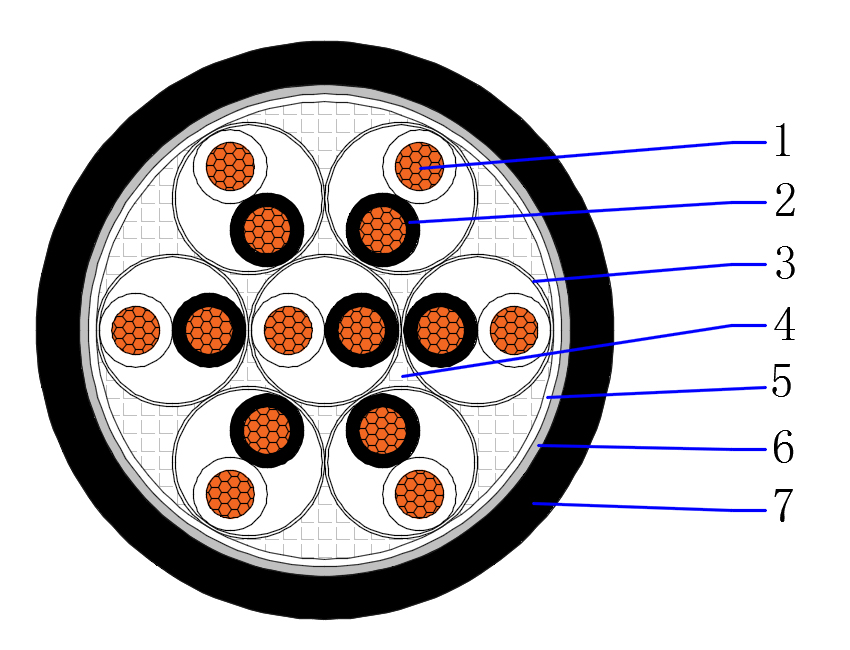

CONSTRUCTION :

Instrumentation Cable XLPE-OS-LSOH BS5308 Cable Part 1 Type1 Construction

Instrumentation Cable XLPE-OS-LSOH BS5308 Cable Part 1 Type1 Construction

Conductor - Plain annealed class 2 stranded or class 5 flexible copper

Insulation - Cross Linked Polyethylene (XLPE)

Binder tape -Polyester tape

Filler - Non-hygroscopic material (if necessary)

Binder tape - Polyester tape

Screen - Al-PET tape with tinned copper drain wire

Outer sheath - Low Smoke Zero Halogen(LSOH)

TECHNICAL :

Instrumentation Cable XLPE-OS-LSOH BS5308 Cable Part 1 Type1 Technical

Conductor operating temperature: -20℃~90℃

Min. installation temperature: 0℃

Minimum bending radius: 5 x overall diameter

|

CONDUCTOR AREA SIZE |

MM 2 |

0.5 |

0.5 |

0.75 |

1.0 |

1.5 |

|

|

CONDUCTOR STRANDING |

NO. X MM |

1 x 0.8 |

16 x 0.2 |

24 x 0.2 |

1 x 1.13 |

7 x 0.53 |

|

|

CONDUCTOR RESISTANCE MAX |

OHM/KM |

36.8 |

39.7 |

26.5 |

18.2 |

12.3 |

|

|

INSULATION RESISTANCE MIN |

GOHM/KM |

5 |

5 |

5 |

5 |

5 |

|

|

CAPACITANCE UNBALANCE AT 1 KHZ(PAIR TO PAIR SCREEN) |

PF/250M |

250 |

|||||

|

MAX. MUTUAL CAPACITANCE @ 1 KHZ FORNON OS OR OS CABLES (EXCEPT ONE-PAIR AND TWO-PAIRS) |

PF/M |

115 |

115 |

115 |

115 |

115 |

|

|

MAX. MUTUAL CAPACITANCE @ 1 KHZ IS/OS CABLES (INCLUDE 1 PAIR AND 2 PAIR) |

PF/M |

75 |

75 |

75 |

75 |

75 |

|

|

MAX. L/R RATIO FOR ADJACENT CORES(INDUCTANCE/RESISTANCE) |

ΜH/OHM |

25 |

25 |

25 |

25 |

40 |

|

|

TEST VOLTAGE |

CORE TO CORE |

V |

1000 |

1000 |

1000 |

1000 |

1000 |

|

CORE TO SCREEN |

V |

1000 |

1000 |

1000 |

1000 |

1000 |

|

|

RATED VOLTAGE MAX |

V |

300/500 |

300/500 |

300/500 |

300/500 |

300/500 |

|