VCT Cable Application

– Mostly used in portable electrical appliances in factories, mines, and farms that use under 0.6/1kV volts or circuits of similar usage.

VCT Cable Standards:

Electrical appliance safety standard

VCT Cable Construction

VCT Cable Construction

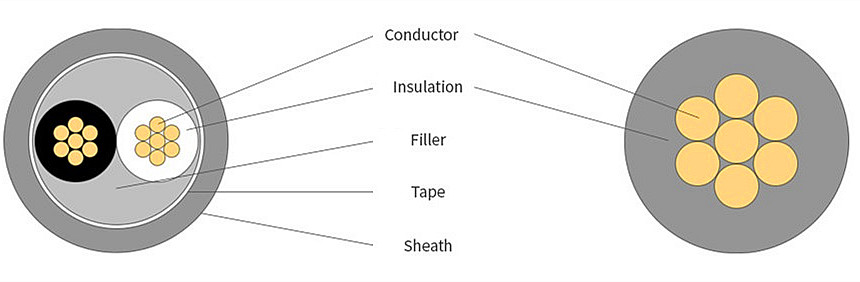

– Conductor : Stranded, composite annealed copper stranded wire (CLASS 5)

– Insulator : PVC

– Sheath : PVC

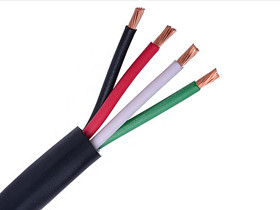

| Number of inner wires | Color |

| 2 inner wires | Black,White |

| 3 inner wires | Black,White,Red or Black,White,Green |

| 4 inner wires | Black,White,Red,Green |