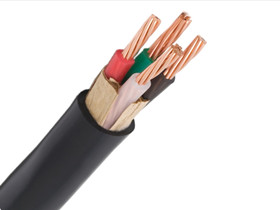

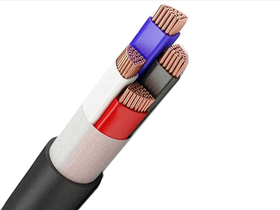

VVG is a power cable with copper conductors, and PVC plastic insulation, as well as with an outer sheath of PVC plastic. It is used for transmission and distribution of the electric power, for internal and external installation.

VVG Cable Application :

Cables are designed for transmission and distribution of electrical energy in stationary conditions for a rated alternating voltage of up to 1000V with a frequency of 50Hz.

It is laid in the ground (trenches), in the premises (tunnels), channels, collectors, industrial premises, on cable overpasses, on bridges, if the cable is not subjected to tensile forces during operation, in the environment of any degree of corrosive activity.

VVG Cable CONSTRUCTION :

Conductive copper conductor, single-wire round or multi-wire round, 1 or 2 classes of flexibility.

In a four-core cable, they lived with a cross section of 70-240 mm2 and can be sector-shaped.

Insulation and sheath – PVC compound.

Core insulation marking is color (solid or stripe) or digital.

Cables are produced with blue zero conductor. Insulated conductors of multicore cables are twisted into a core.

VVG Cable TECHNICAL :

1. Limit operating ambient temperatures from -50 to +50.

2. Relative air humidity up to 98% at a temperature of 35 ° C.

3. The nominal alternating voltage is 1 kV at a frequency of 50 Hz.

4. The test voltage is AC, 50Hz, 3500V for 10 minutes.

5. The insulation resistance is not less than 0.005 mOhm per kilometer.

6. The minimum bend radius is approximately 15 cable diameters.

7. Nominal cross-section:

copper single-wire core - from 1.5 to 10 mm2;

copper stranded wire - from 16 to 1000 mm2;

8. Cables are manufactured single-, double-, three-core, four-core and five-core.

Four-core cables are manufactured with single-section or single-core conductors.

PARAMETER :

| Number and nominal cross-section of current-carrying conductors | Outer cable diameter | Permissible current loads at alternating current | Operating temperature range | Minimum bending radius when laying | Phase insulation thickness | Cable weight | |

| mm | air | soil | °C | mm | mm | kg/km | |

| 1×1,5 | 7 | 22 | 30 | – 50 + 50 | 70 | 0,8 | 50 |

| 1×2,5 | 7 | 30 | 39 | – 50 + 50 | 70 | 0,8 | 60 |

| 1×4 | 8 | 39 | 50 | – 50 + 50 | 80 | 1 | 80 |

| 1х6 | 9 | 50 | 62 | – 50 + 50 | 90 | 1 | 100 |

| 1х10 | 9 | 68 | 83 | – 50 + 50 | 90 | 1 | 150 |

| 1х16 | 11 | 89 | 107 | – 50 + 50 | 110 | 1 | 220 |

| 1х25 | 12 | 121 | 137 | – 50 + 50 | 120 | 1,2 | 320 |

| 1х35 | 13 | 147 | 163 | – 50 + 50 | 130 | 1,2 | 420 |

| 1х50 | 15 | 179 | 194 | – 50 + 50 | 150 | 1,4 | 550 |