The N2XBY cable represents a robust power transmission solution engineered for demanding industrial environments. This steel wire armoured cable delivers reliable electrical performance in challenging conditions where mechanical protection is paramount.

Key Features & Benefits

Superior Mechanical Protection

The double galvanized steel tape armoring provides exceptional resistance to mechanical damage, making N2XBY cables ideal for harsh industrial environments and underground installations.

Reliable XLPE Insulation

Cross-linked polyethylene (XLPE) insulation ensures excellent electrical properties, thermal stability, and long-term performance under varying load conditions.

Versatile Installation Options

Designed for both fixed and flexible installations, these cables adapt to various industrial power distribution requirements while maintaining structural integrity.

Technical Specifications

Electrical Characteristics

| Parameter | Specification |

|---|---|

| Primary Voltage Rating | 0.6/1kV (Uo/U) |

| Maximum System Voltage | 1.2kV (Um) |

| DC Test Voltage | 1.8kV (core-earth/core-core) |

| AC Test Voltage | 4kV |

| Frequency Rating | 50Hz AC systems |

Temperature Performance

| Operating Condition | Temperature Range |

|---|---|

| Flexible Installation | +5°C to +90°C |

| Fixed Installation | -35°C to +90°C |

| Short Circuit Maximum | +250°C (5 seconds max) |

Installation Parameters

| Cable Type | Minimum Bend Radius |

|---|---|

| Single Core Configuration | 15 × overall diameter |

| Multi Core Configuration | 12 × overall diameter |

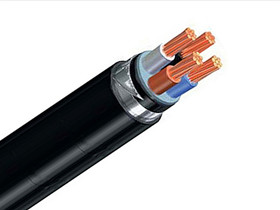

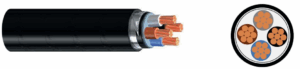

Cable Architecture

N2XBY Cable Construction

Layer-by-Layer Construction

- Core Conductor: High-quality copper construction

- Class 1: Solid conductor option

- Class 2: Stranded conductor option

- Primary Insulation: Cross-linked polyethylene (XLPE) for superior electrical performance

- Cable Core Assembly:

- Non-hygroscopic filler material

- Non-hygroscopic binder tape system

- Inner Protection: Polyvinyl chloride (PVC) inner sheath

- Mechanical Armor: Double galvanized steel tape providing robust protection

- Outer Protection: Durable PVC outer sheath for environmental resistance

Industrial Applications

Primary Use Cases

- Industrial Power Distribution: Main power feeds for manufacturing facilities

- Underground Infrastructure: Tunnel installations and buried power lines

- Fixed Industrial Equipment: Permanent power connections for heavy machinery

- Harsh Environment Power: Applications requiring superior mechanical protection

Installation Environments

- Underground cable tunnels and ducts

- Industrial facilities with mechanical hazards

- Direct burial applications

- Cable tray installations in industrial settings

- Areas requiring rodent and impact protection

Compliance & Standards

International Standards Adherence

- IEC 60228: Conductor specifications and requirements

- IEC 60502-1: Power cable standards for 1kV-30kV applications, specifically covering 1kV and 3kV rated cables with extruded insulation systems

Design Advantages

Structural Benefits

The rigid construction with large bending radius ensures long-term mechanical stability while the steel wire armor provides unmatched protection against external forces.

Electrical Performance

XLPE insulation technology delivers excellent dielectric properties, low power losses, and superior thermal characteristics for consistent power transmission.

Environmental Resistance

The dual PVC sheath system provides excellent protection against moisture, chemicals, and environmental contaminants commonly found in industrial settings.

Installation Considerations

Handling Requirements

Due to the rigid nature and armored construction, proper installation equipment and techniques are essential to maintain cable integrity and performance.

System Integration

N2XBY cables integrate seamlessly with standard industrial electrical systems and distribution equipment designed for 0.6/1kV applications.