Three Core 12/20KV Medium Voltage Steel Tape Armoured Cable Application

XLPE(Cross linked polyethylene) insulated cable functions well for electricity transmission and distribution lines for its excellent electrical and physical properties, including the advantage of simplicity in construction, lightness in weight; convenience in application besides its excellent electrical, thermal, mechanical and anti-chemical corrosion properties.

GB/12706-2008, IEC60502,IEC 60228,IEC60332 BS 5467,BS 6622 , IS 1554 , IS 7098and ICEA S-66-524 etc.

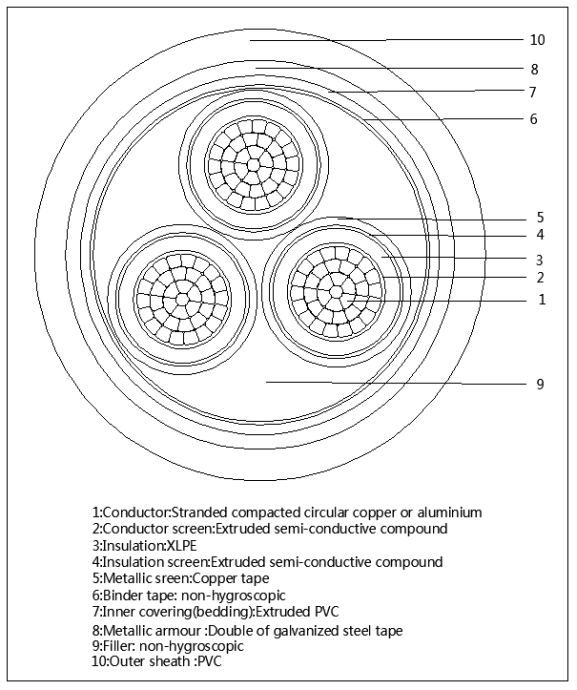

CONSTRUCTION :

Three Core 12/20KV Medium Voltage Steel Tape Armoured Cable Construction

Three Core Medium Voltage Steel Tape Armoured Cable Construction

Conductor: Plain annealed stranded compacted circular copper or aluminium conductor to IEC60228 class 2

Conductor Screen: Extruded semi-conductive compound

Insulation: XLPE (cross-linked polyethylene) rated at 90°C

Insulation Screen: Extruded semi-conductive compound

Metallic Screen: copper tape or a concentric layer of copper wires

Color for core identification: Red, Yellow ,Blue tape shall be applied between insulation screen and metallic screen ( The above identifying can be changed as user requirement)

Assembly : Three screened cores are laid up together ,if necessary filled with non-hygroscopic material compatible with insulation and covered with a layer of PVC sheath

Inner Sheath: Extruded layer of PVC ST2 or PE , LSZH

Armour : Double of galvanized steel tape or galvanized steel wire for three core power cable , Double of aluminium tape or aluminium wire for single power cable ,

Outer Sheath: PVC type ST2 to IEC 60502 or PE ,LSZH