Single core medium voltage unarmoured cables are engineered for reliable electrical power distribution in demanding industrial and utility applications. Designed for nominal voltages ranging from 3.8/6.6KV to 19/33KV at 50Hz frequency, these cables deliver superior performance across diverse installation environments while maintaining excellent electrical and mechanical properties.

Technical Specifications

- Voltage Rating: 8.7/15KV (Uo/U)

- Frequency: 50Hz

- Voltage Range: 3.8/6.6KV to 19/33KV

- Configuration: Single core unarmoured construction

- Standards Compliance: BS 6622, IEC 60502-2, BS 7835 (LSZH Version)

Applications & Installation Environments

Primary Applications

- Power supply stations: Main distribution and feeder circuits

- Industrial facilities: Heavy-duty power distribution for manufacturing plants

- Switchboards: High-voltage switching and control installations

- Substations: Transformer connections and distribution panels

Installation Environments

- Indoor installations: Controlled environment applications in substations and industrial buildings

- Cable ducts: Protected underground routing systems

- Outdoor installations: Weather-resistant applications with appropriate protection

- Underground direct burial: Suitable for buried installations with proper protection

- Submerged applications: Water-resistant construction for underwater crossings

- Cable trays: Industrial rack-mounted installations

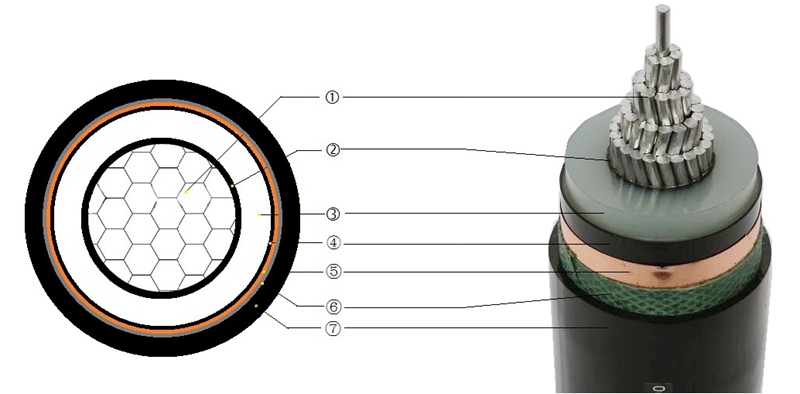

Cable Construction

Conductor

- Material Options:

- Plain annealed copper wire (high conductivity)

- Aluminium wire (lightweight, cost-effective)

- Construction:

- Copper conductors: Stranded Class 2 configuration per IEC standards

- Aluminium conductors: Solid or stranded Class 2 configuration

- Benefits: Optimized for current carrying capacity and mechanical flexibility

Conductor Screen

- Material: Semi-conducting cross-linkable compound

- Application: Extruded layer directly over conductor

- Function: Ensures uniform electric field distribution and reduces electrical stress

Insulation System

- Primary Options:

- XLPE (Cross-Linked Polyethylene): Superior thermal and electrical properties

- EPR (Ethylene Propylene Rubber): Enhanced flexibility and temperature resistance

- Performance: Excellent dielectric strength and long-term stability

- Temperature Rating: High continuous operating temperature capability

Insulation Screen

- Construction: Extruded semi-conducting cross-linkable compound

- Application: Applied directly over primary insulation

- Function: Controls electric field at insulation/metallic layer interface

Metallic Layer (Fault Protection)

- Configuration Options:

- Copper tape wrapping

- Concentric copper wire layer

- Combination of copper tapes and wires

- Function: Fault current path and electromagnetic shielding

Over Sheath (Outer Protection)

- Standard Options:

- PVC: Cost-effective, good chemical resistance

- MDPE: Enhanced mechanical properties and environmental resistance

- Premium Option:

- LSZH (Low Smoke Zero Halogen): Fire-safe applications with reduced toxic emissions

Key Performance Features

Electrical Performance

- High dielectric strength for reliable insulation

- Low power losses with optimized conductor design

- Excellent impulse voltage withstand capability

- Superior partial discharge resistance

Mechanical Properties

- Robust construction for demanding installation conditions

- Excellent tensile strength and flexibility

- Resistance to mechanical damage during installation

- Long-term stability under operational stresses

Environmental Resistance

- UV resistance for outdoor applications

- Chemical resistance to industrial environments

- Moisture resistance for underground and submerged installations

- Temperature stability across wide operating range

Safety Features

- LSZH option available for fire-sensitive applications

- Metallic screening provides fault protection

- Complies with international safety standards

- Low flame propagation characteristics

Installation Advantages

- Versatile mounting: Suitable for multiple installation methods

- Reduced installation time: Single core design simplifies routing and termination

- Flexible configuration: Adaptable to various system layouts

- Standard termination: Compatible with industry-standard accessories

Quality Assurance & Standards

- International Compliance: BS 6622, IEC 60502-2 standards

- Fire Performance: BS 7835 compliance for LSZH variants

- Quality Testing: Comprehensive electrical, mechanical, and environmental testing

- Certification: Third-party testing and certification available

Selection Guide

| Application | Recommended Construction | Key Benefits |

|---|---|---|

| Indoor Substations | XLPE/PVC or XLPE/LSZH | Fire safety, space efficiency |

| Industrial Plants | XLPE/PVC, Copper conductor | High current capacity, durability |

| Underground Installation | XLPE/MDPE | Moisture resistance, longevity |

| Water Crossings | EPR/MDPE | Enhanced water resistance |

| Cable Tray Systems | XLPE/LSZH | Fire safety, easy installation |

Technical Support

Our engineering team provides comprehensive support for:

- Cable selection and sizing calculations

- Installation method recommendations

- Accessories and termination guidance

- Custom specifications for specialized applications