The 18/30kV Three Core Medium Voltage Unarmored Cable is engineered for power transmission and distribution systems in utility networks, industrial facilities, and infrastructure projects operating at a nominal voltage of 30kV.

Thanks to the use of XLPE (Cross-linked Polyethylene) insulation, this cable offers a superior combination of dielectric strength, mechanical durability, thermal stability, and chemical resistance. It is especially suitable for installations where armor protection is not required, but where reliable, long-lasting medium voltage performance is essential.

Whether installed in trays, ducts, or directly underground (where conditions allow), this cable ensures safe and efficient power delivery for medium voltage applications.

Compliance Standards

This cable meets or exceeds the following national and international standards:

IEC 60502-2

IEC 60228

IEC 60332-1

GB/T 12706-2008

BS 5467 / BS 6622

IS 7098 / IS 1554

ICEA S-66-524

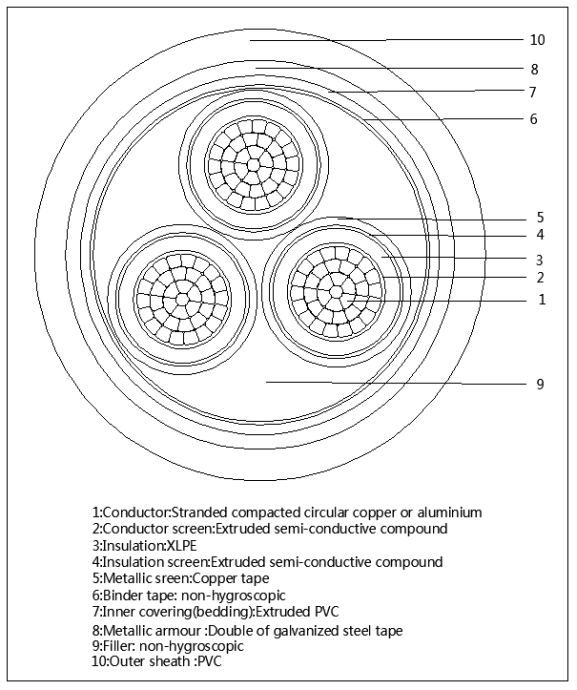

CONSTRUCTION

Three Core Medium Voltage Unarmored Cable Construction

| Component | Description |

|---|---|

| Conductor | Stranded and compacted plain annealed copper or aluminum conductor (IEC 60228 Class 2) |

| Conductor Screen | Extruded layer of semi-conductive compound |

| Insulation | High-quality XLPE (Cross-linked Polyethylene), operating temperature up to 90°C |

| Insulation Screen | Extruded semi-conductive layer over insulation |

| Metallic Screen | Copper tape or concentric copper wires applied to each core |

| Core Identification | Red, Yellow, Blue (identification tapes applied between insulation and screen) (Other color codes available on request) |

| Assembly | Three insulated and screened cores laid up together with optional non-hygroscopic fillers |

| Outer Sheath | Black PVC (Type ST2 per IEC 60502), optional PE or LSZH outer sheath |

Advantages of 18/30kV Unarmored XLPE Cables

Lightweight design simplifies handling and installation

High current-carrying capacity with reduced dielectric losses

Ideal for indoor and outdoor fixed installations in non-armored environments

Excellent resistance to chemical agents, abrasion, and weathering

Available in copper or aluminum conductor options based on project requirements