In the vast expanse of the ocean, every voyage a vessel embarks on relies on a stable, efficient, and secure electrical system. Within this system, shipboard cable plays a pivotal role, serving as the 'lifeline' connecting various onboard equipment. Unlike land-based cables, the design and manufacturing of marine cables must meet extremely stringent requirements to withstand the harsh marine environment, including high humidity, salt spray corrosion, oil contamination, vibration, and fire hazards.

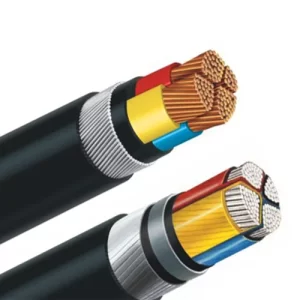

Marine armored cable

Part 1: Core Technology and Classification of Shipboard Cables

1.1 Structure and Materials

The design of a shipboard cable is aimed at providing maximum reliability. The core is typically made of tinned copper to prevent oxidation in humid environments. The choice of insulation and sheathing materials is crucial; they must be resistant to oil, acids, alkalis, and UV radiation.

A key feature is armoring. Marine armored cable adds a protective metal layer, such as steel wire or copper braiding, to the outer sheath. This provides superior mechanical protection, preventing damage from external impact or compression, which is particularly important in confined or vulnerable areas.

1.2 Performance Standards and Ratings

To ensure safety in emergencies, shipboard cables must meet rigorous performance standards. Many marine cables are low smoke zero halogen (LSZH), a material that does not produce toxic smoke or halogen gases when burned, thereby protecting the lives of personnel on board. Additionally, they are rated for different levels of fire resistance to ensure power supply can be maintained during a fire.

1.3 Main Classifications

Based on their function and purpose, shipboard cables can be classified into:

- Power Cables: Responsible for supplying power to the main systems and large equipment on the vessel.

- Control Cables: Used for transmitting control signals, such as shipboard electrical cable.

- Instrumentation Cables: Used for transmitting low-level instrument signals.

- Communication Cables: Used for internal and external communication networks on the ship.

Part 2: Specialized Applications of Shipboard Cables

The application of shipboard cables extends beyond simple power transmission, playing a crucial role in certain specialized uses:

2.1 Submarine Cable Laying Vessels

This is a highly specialized field. A cable ship, also known as a cable layer, is a specialized vessel dedicated to laying communication cables or submarine optical fibers on the seabed. The cables used by these vessels possess extremely high strength and pressure resistance to withstand the deep-sea environment. Understanding the operational principles of a cable laying vessel and its associated cables is key knowledge in the marine engineering field.

2.2 Other Specialized Applications

- Offshore Oil Rigs and Drilling Platforms: Cables on these platforms must have extremely strong resistance to oil and chemical corrosion.

- Naval Vessels: Military-grade shipboard cables must meet additional standards for electromagnetic compatibility (EMC) and shock resistance.

Part 3: Procurement and Maintenance of Shipboard Cables

3.1 Procurement Considerations

When purchasing shipboard cables, it is essential to make selections based on the specific application environment and requirements. Key considerations include: voltage rating, current carrying capacity, conductor cross-sectional area, the need for armoring, and compliance with certification from classification societies (e.g., ABS, DNV GL, LR).

3.2 Installation and Maintenance

Correct installation is crucial for the long-term performance of the cable. This includes proper routing, reliable termination, and preventing the cable from being bent at too tight a radius. Regular inspection and maintenance of cables can effectively extend their service life and help in the early detection of potential safety hazards.

Conclusion: Shipboard Cables - The Unsung Heroes of Maritime Safety

Shipboard cables are the unsung heroes that ensure a vessel's safe and stable navigation in a complex and ever-changing marine environment. From simple shipboard wire to complex armored cables, each type is meticulously designed to meet unique challenges. In the future era of electric and autonomous ships, the importance of shipboard cables will become even more pronounced, as they continue to be the solid foundation for reliable maritime operations.