Proper grounding is critical in electrical systems—for both safety and performance. Two of the most commonly used materials for grounding are braided ground straps and ground wires (typically solid or stranded copper). Though both serve the same function—establishing a reliable electrical path to ground—they differ in construction, flexibility, conductivity, and ideal use cases.

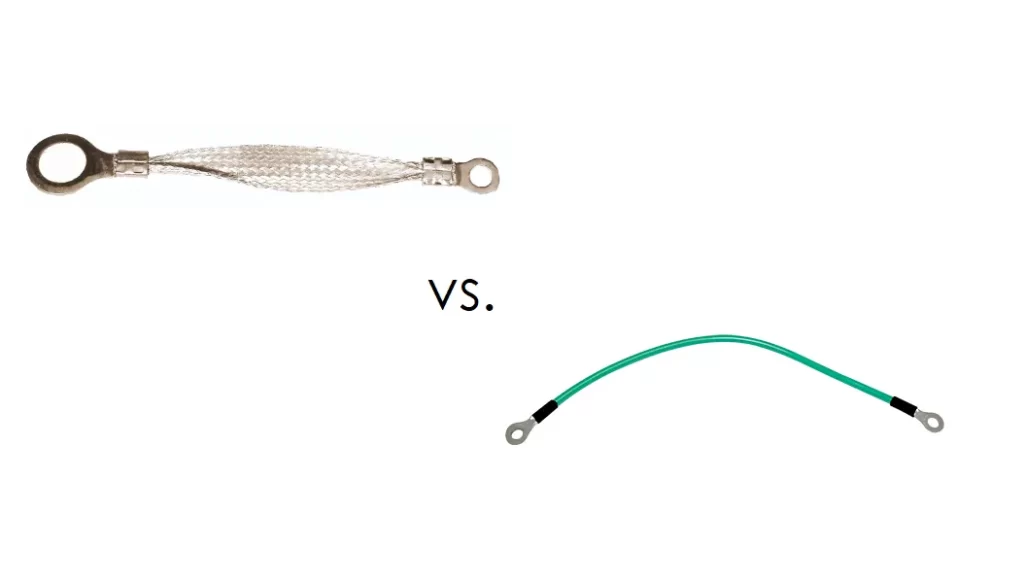

braided ground strap vs wire

In this article, we’ll compare braided ground straps vs. traditional wire in terms of structure, applications, pros and cons, and how to choose the right one for your project.

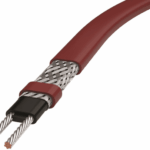

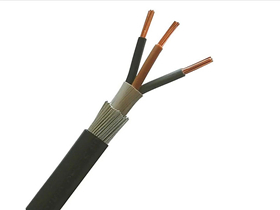

🔧 What Is a Braided Ground Strap?

A braided ground strap is made from tightly woven strands of tinned or bare copper. It’s typically flat, flexible, and highly conductive, often used to connect two metallic surfaces (such as a chassis and frame) while allowing movement or vibration.

These are commonly seen in:

-

Vehicle or aircraft bonding

-

Electrical cabinets

-

Battery grounding

-

High-vibration environments

-

RF and EMI shielding

Key features:

-

Flat, woven design

-

High surface area

-

Excellent flexibility and vibration resistance

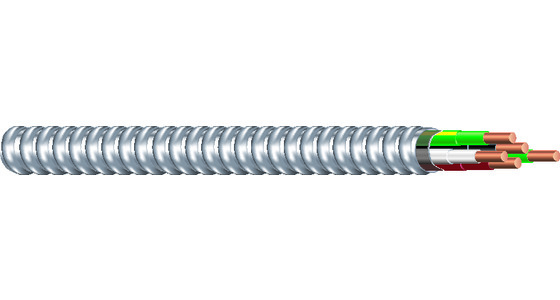

🔌 What Is a Ground Wire?

A ground wire is a single conductor—either solid or stranded—that provides a direct path to earth ground. It’s usually round, available in a variety of gauges, and insulated or bare depending on the application.

Ground wires are used in:

-

Residential and commercial wiring

-

Electrical panels

-

Power distribution

-

General equipment grounding

Key features:

-

Circular profile

-

Available in solid or stranded form

-

Typically less flexible than braided straps (especially in larger gauges)

🔍 Comparison Table: Braided Ground Strap vs Wire

| Feature | Braided Ground Strap | Ground Wire |

|---|---|---|

| Flexibility | Extremely flexible, ideal for movement | Less flexible (especially solid wire) |

| Vibration Resistance | Excellent | Moderate (depends on strand count) |

| Installation | Easily conforms to irregular surfaces | More rigid, harder to bend in tight spots |

| Current Carrying Capacity | High surface area, better for high frequency (skin effect) | Good for DC and low-frequency AC |

| Size & Space Efficiency | Flat profile, saves space | Round profile, takes more space |

| EMI/RFI Shielding | Provides some shielding capabilities | Minimal |

| Durability | Tolerates repeated flexing | Prone to fatigue if flexed often |

| Cost | Slightly more expensive | Generally cheaper per foot |

🧰 When to Use a Braided Ground Strap

-

Vibrating environments: Cars, trains, aircraft, and industrial equipment where movement is constant.

-

EMI shielding needs: Helps with radio frequency interference in sensitive electronics.

-

Space constraints: The flat shape can fit under panels or in tight control boxes.

-

Bonding across hinges or joints: Keeps continuity between moving parts.

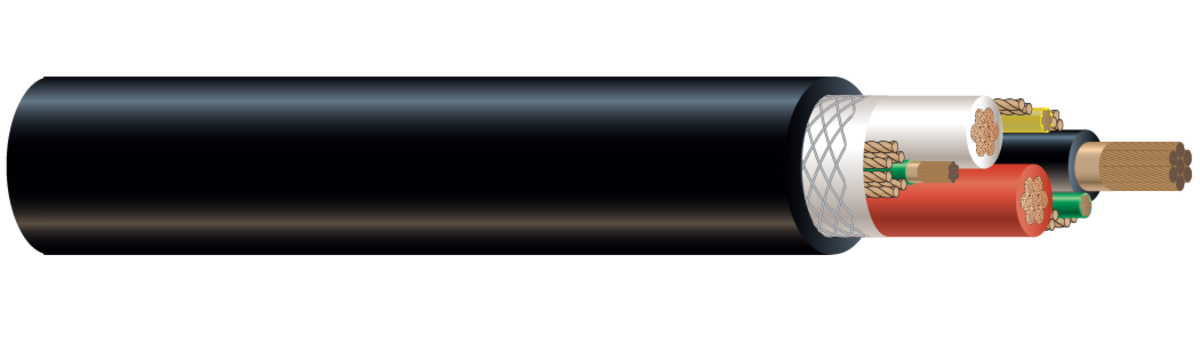

🔌 When to Use Ground Wire

-

General electrical grounding: Homes, offices, commercial buildings.

-

Low-frequency or DC circuits: Efficient for standard ground paths.

-

Static installations: Ideal when no flex or movement is expected.

-

Longer cable runs: Often cheaper and easier to route in conduit.

⚡ Electrical Performance: Which Grounds Better?

In low-frequency AC and DC systems, both wire and braid are effective for grounding. However, at higher frequencies, such as in RF or lightning protection systems, braided straps tend to perform better due to the skin effect, where current travels along the surface. The larger surface area of a braided strap offers less impedance under these conditions.

🌍 Real-World Examples

-

Automotive Grounding: Braided straps connect engine blocks to the chassis because they resist vibration and handle high current.

-

Electrical Panels: Wires are used for system grounding inside switchboards and circuit panels.

-

Data Centers: Braided straps are used to ground racks and shielded enclosures to reduce EMI.

✅ Summary: Which Should You Use?

| Need | Recommended Option |

|---|---|

| Flexibility and vibration | Braided ground strap |

| Basic grounding in a panel | Ground wire |

| EMI or RF shielding | Braided strap |

| Cost-sensitive project | Ground wire |

| Compact installation space | Braided strap |

| Long, static wire runs | Ground wire |

Final Thoughts

Both braided ground straps and ground wires are essential tools in electrical grounding—but the right choice depends on your specific application. If your system involves motion, vibration, or high-frequency signals, braided straps are often the better option. For static, standard electrical installations, a simple ground wire may be more practical and cost-effective.

Before deciding, consider the environment, electrical load, mechanical stresses, and long-term reliability needs.