You're staring at a cable specification sheet. One says 'YJV 3×120+1×70.' Another reads 'THHN 4 AWG.' A third shows 'H07RN-F 5G2.5.' What do these codes actually mean? If you're sourcing cables internationally or trying to find equivalent products across different markets, understanding these designation systems isn't optional—it's critical.

Cable Designation System Decoded

I spent two weeks interviewing cable engineers, comparing standards documents, and decoding hundreds of cable specifications. Here's everything you need to know about cable naming conventions across the world's three major standards systems.

Why Cable Designation Systems Matter

Before we dive into the codes, understand this: cable designation systems exist to compress complex technical specifications into standardized shorthand. A properly decoded cable designation tells you:

- Conductor material and construction

- Insulation type and voltage rating

- Sheath material and protection level

- Number of cores and cross-sectional area

- Special properties (flame retardant, oil resistant, etc.)

- Application environment and installation method

Miss one character in the designation, and you might end up with a cable rated for 300V when you need 600V, or PVC insulation when you need heat-resistant silicone.

Chinese GB Standard (National Standard)

Basic Structure: Type-Insulation-Sheath-Special Features

The Chinese GB (Guobiao) system follows this general pattern:

[Category][Insulation][Sheath][Special Characteristics] + [Core Configuration]

Breaking Down a Real Example: YJV22 3×120+1×70

Let's decode this common power cable specification:

Y = Type: Cross-linked polyethylene (XLPE) insulated power cable J = Conductor material: Copper (if 'L' appears, it's aluminum) V = Sheath material: PVC (Polyvinyl chloride) 22 = Armor: Double steel tape armored 3×120 = Three main conductors, each 120 mm² +1×70 = One additional conductor (typically ground/earth), 70 mm²

Translation: This is a copper conductor, XLPE-insulated, PVC-sheathed, steel-tape-armored power cable with three 120 mm² phase conductors and one 70 mm² ground conductor.

Common GB Designation Letters

Conductor Material:

- (blank) = Copper (default)

- L = Aluminum

- T = Copper (explicit marking, older standard)

Insulation Type:

- V = PVC (Polyvinyl chloride)

- Y = XLPE (Cross-linked polyethylene)

- YJ = XLPE (full designation)

- X = Rubber insulation

- F = Polypropylene

Sheath Material:

- V = PVC sheath

- Y = Polyethylene sheath

- (blank) = No sheath (insulated only)

- F = Chloroprene/neoprene sheath

Armor/Protection:

- 22 = Double steel tape armor

- 23 = Double steel tape armor + outer sheath

- 32 = Steel wire armor

- 33 = Steel wire armor + outer sheath

- 42 = PVC sheath over armor

- 43 = PE sheath over armor

Special Characteristics:

- ZR = Flame retardant (Zu Ran)

- NH = Fire resistant (Nai Huo)

- WDZ = Low smoke zero halogen

- DJ = Computer/instrumentation cable

- KVV = Control cable, PVC insulated and sheathed

Practical GB Examples

KVVP 7×1.5

- K = Control cable

- V = PVC insulated

- V = PVC sheathed

- P = Copper wire braided shield

- 7×1.5 = Seven cores, 1.5 mm² each

- Use case: Industrial control systems, instrumentation

WDZN-YJY 4×25+1×16

- WDZ = Low smoke zero halogen

- N = Fire resistant

- YJ = XLPE insulated

- Y = Polyethylene sheathed

- 4×25+1×16 = Four 25 mm² conductors + one 16 mm² ground

- Use case: High-rise buildings, critical infrastructure

RVV 3×2.5

- R = Flexible conductor

- V = PVC insulated

- V = PVC sheathed

- 3×2.5 = Three cores, 2.5 mm² each

- Use case: Power supply cords, flexible connections

American NEC/UL Standard

Basic Structure: Material-Insulation-Application

The American system (governed by National Electrical Code and UL standards) uses a different logic:

[Conductor Material][Insulation Type][Special Properties] + [Size in AWG/kcmil]

Breaking Down a Real Example: THHN 10 AWG

T = Thermoplastic insulation H = Heat resistant (75°C) H = Heat resistant (90°C) - yes, double H means higher rating N = Nylon jacket over insulation 10 AWG = American Wire Gauge size #10 (5.26 mm²)

Translation: This is a thermoplastic-insulated, heat-resistant (90°C), nylon-jacketed building wire suitable for dry and damp locations, sized at 10 AWG.

Common NEC/UL Designation Letters

Insulation Type:

- T = Thermoplastic (typically PVC)

- R = Rubber or synthetic rubber

- X = Cross-linked synthetic polymer (XLPE)

- SA = Silicone rubber

Heat Resistance:

- H = Heat resistant, 75°C

- HH = Heat resistant, 90°C

- (blank) = Standard 60°C rating

Special Properties:

- W = Wet location rated

- -2 = 90°C rating in dry and damp locations

- N = Nylon jacket

- U = Underground rated

- F = Fixture wire (flexible)

Application/Construction:

- MTW = Machine Tool Wire

- TEW = Thermoplastic Equipment Wire

- USE = Underground Service Entrance

- UF = Underground Feeder

- NM = Non-metallic sheathed cable (Romex)

- MC = Metal-clad cable

- SO/SOOW = Service cord, oil resistant

Wire Size: AWG vs kcmil

American cables use two sizing systems:

AWG (American Wire Gauge): Sizes 0000 (4/0) through 40

- Smaller numbers = larger wire (10 AWG is larger than 14 AWG)

- Common sizes: 14 AWG (2.08 mm²), 12 AWG (3.31 mm²), 10 AWG (5.26 mm²)

kcmil (thousands of circular mils): For conductors larger than 4/0

- 250 kcmil ≈ 127 mm²

- 500 kcmil ≈ 253 mm²

- 1000 kcmil ≈ 507 mm²

Practical NEC Examples

THWN-2 12 AWG

- T = Thermoplastic

- H = Heat resistant 75°C

- W = Wet location rated

- N = Nylon jacket

- -2 = 90°C dry/damp rating

- 12 AWG = 3.31 mm²

- Use case: General building wiring, conduit installation

XHHW-2 4/0 AWG

- X = Cross-linked polyethylene

- H = Heat resistant 75°C

- H = Heat resistant 90°C

- W = Wet location approved

- -2 = Enhanced 90°C rating

- 4/0 = 107 mm²

- Use case: Service entrance, feeder cables

MTW 16 AWG

- M = Machine tool wire

- T = Thermoplastic

- W = Wet location

- 16 AWG = 1.31 mm²

- Use case: Control panels, machine wiring

SOOW 12/3

- S = Service cord, 600V

- OO = Oil resistant (both insulation and jacket)

- W = Weather resistant

- 12/3 = Three conductors of 12 AWG

- Use case: Portable power tools, outdoor equipment

European IEC/HD Standard

Basic Structure: Harmonized Designation Code

European cables follow the harmonized IEC 60227 (flexible cords) and IEC 60245 (rubber cables) or HD (Harmonization Document) system:

[Harmonization Code][Voltage Rating][Construction][Insulation/Sheath][Conductor Count and Size]

Breaking Down a Real Example: H07RN-F 5G2.5

H = Harmonized cable 07 = Voltage rating: 450/750V R = Rubber insulation N = Polychloroprene (neoprene) sheath -F = Flexible conductor 5G = Five cores including green/yellow ground 2.5 = 2.5 mm² cross-sectional area per conductor

Translation: This is a harmonized 450/750V flexible cable with rubber insulation, neoprene sheath, five cores (including ground), each 2.5 mm² in cross-section.

European Voltage Codes

- 03 = 300/300V (light duty)

- 05 = 300/500V (medium duty)

- 07 = 450/750V (heavy duty, most common)

Insulation and Sheath Codes

First Letter (Insulation):

- V = PVC

- R = Rubber (EPR, natural rubber, etc.)

- S = Silicone rubber

- E = Polyethylene (PE)

- X = Cross-linked compounds

Second Letter (Sheath):

- V = PVC

- R = Rubber

- N = Polychloroprene (neoprene)

- J = Glass fiber braid

- (blank) = No sheath

Third Letter (Construction):

- H = Flat separable (like zip cord)

- -F = Flexible (fine wire stranding)

- -U = Rigid (solid or stranded)

- -K = Flexible for fixed installation

Core Configuration Codes

G = With green/yellow ground conductor

- 3G1.5 = Three cores including ground, 1.5 mm² each

- 5G2.5 = Five cores including ground, 2.5 mm² each

X = Without ground, cores with insulation only

- 3X1.5 = Three insulated cores, no ground, 1.5 mm² each

Number only = Cores with common sheath

- 2×1.5 = Two cores in common sheath, 1.5 mm² each

Practical European Examples

H05VV-F 3G1.0

- H = Harmonized

- 05 = 300/500V

- V = PVC insulation

- V = PVC sheath

- -F = Flexible conductor

- 3G1.0 = Three cores including ground, 1.0 mm²

- Use case: Light-duty appliance cords, indoor use

H07RN-F 4G6

- H = Harmonized

- 07 = 450/750V

- R = Rubber insulation

- N = Neoprene sheath

- -F = Flexible

- 4G6 = Four cores including ground, 6 mm²

- Use case: Industrial equipment, outdoor power distribution

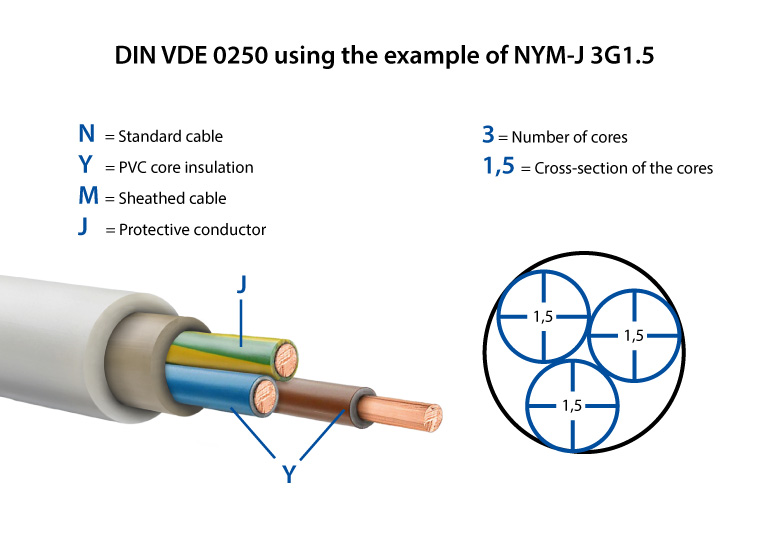

NYM-J 5×1.5

- N = National standard designation (German)

- Y = PVC insulation

- M = Mantel (German for sheath/jacket)

- -J = With green/yellow ground

- 5×1.5 = Five cores, 1.5 mm² each

- Use case: Fixed building installation (very common in Europe)

LIYCY 4×0.25

- LI = Flexible control cable

- Y = PVC insulation

- C = Copper screen (shield)

- Y = PVC outer sheath

- 4×0.25 = Four cores, 0.25 mm² each

- Use case: Signal and control applications

Cross-Reference Guide: Finding Equivalents

One of the biggest challenges in international cable sourcing is finding equivalent products across standards. Here's a practical comparison:

Power Cable Equivalents

| Application | Chinese GB | American NEC | European IEC |

|---|---|---|---|

| Building wire (small) | BV 2.5 | THHN 14 AWG | H07V-U 2.5 |

| Building wire (medium) | BV 6 | THHN 10 AWG | H07V-U 6 |

| Flexible power cord | RVV 3×1.5 | SJOW 16/3 | H05VV-F 3G1.5 |

| Heavy-duty power | YJV 3×25+1×16 | XHHW 3 AWG | NYY-J 4×25 |

| Armored power | YJV22 3×95+1×50 | MC Cable 1/0 | NYY2Y 4×95 |

Control Cable Equivalents

| Application | Chinese GB | American NEC | European IEC |

|---|---|---|---|

| Shielded control | KVVP 7×1.5 | PLTC 16 AWG 7C | LIYCY 7×1.5 |

| Unshielded control | KVV 12×1.0 | MTW 18 AWG 12C | YSLY 12×1.0 |

| Flexible control | RVVP 4×0.5 | SOOW 20/4 | H05VV-F 4G0.75 |

Important Notes on Equivalency

Voltage ratings don't directly convert:

- Chinese 0.6/1kV ≈ American 600V ≈ European 450/750V (for low voltage)

- Always verify actual voltage requirements for your application

Conductor sizing differs:

- American AWG is logarithmic (backwards: smaller number = larger wire)

- Chinese/European mm² is linear and direct

- Use conversion tables—never estimate

Standards have different safety margins:

- UL standards often require derating in certain conditions

- IEC may allow higher current in the same size

- GB standards include specific installation method considerations

Certification doesn't transfer:

- A cable certified to GB standard is NOT automatically UL or CE compliant

- Re-testing and certification required for different markets

Practical Tips for Specifying Cables

When Ordering from Chinese Manufacturers

Always specify:

- Full GB designation (e.g., YJV22 3×120+1×70)

- Voltage rating (0.6/1kV, 8.7/10kV, etc.)

- Installation method if critical

- Required certifications (CCC, UL, CE, etc.)

- Testing standards needed

Common pitfall: Assuming 'copper conductor' means pure copper. Specify if you need oxygen-free copper (OFC) or specific conductivity requirements.

When Ordering to American Standards

Critical specifications:

- Wire type designation (THHN, XHHW, etc.)

- AWG size (don't mix with mm²)

- Voltage rating (300V, 600V, etc.)

- Number of conductors (for multi-conductor cables)

- Jacket color if relevant

Common pitfall: Forgetting to specify -2 suffix. THHN vs THHN-2 has different temperature ratings.

When Ordering to European Standards

Must include:

- Harmonization code (H05, H07, etc.)

- Construction code (complete, e.g., H07RN-F)

- Core configuration with G or X designation

- Cross-sectional area in mm²

- Applicable CE directives if for commercial sale

Common pitfall: Confusing '3G1.5' (three cores including ground) with '3×1.5' (three cores, ground status unclear).

Special Cases and Industry-Specific Designations

Automotive Cables

- German FLRY: Fahrzeug Leitung (vehicle wire), e.g., FLRY-B 1.5 mm²

- Japanese AV/AVS: Automotive Vehicle wire, e.g., AVS 0.5 sq

- SAE Standards: J1128, J1678 in North America

Marine Cables

- IEC 60092: Marine cable standard, e.g., NSHXÖU 3×6 mm²

- UL 1309: Marine shipboard cable, e.g., Type TC-ER

- Chinese CJPF: Ship cable designation

Railway Cables

- EN 50264/50306: Railway rolling stock cables

- TB/T standards: Chinese railway standards

- ASTM: American railway applications

Solar/Photovoltaic Cables

- Chinese: PV1-F 1×4 mm²

- European: H1Z2Z2-K 1×4 mm²

- American: PV Wire, 10 AWG USE-2

Quick Reference Decoder Chart

Chinese GB Quick Reference

| Position | Code | Meaning |

|---|---|---|

| 1st | Y/V/X | Insulation type |

| 2nd | J/L/blank | Conductor material |

| 3rd | V/Y/F | Sheath material |

| 4th+ | 22/32/P | Armor or shield |

| Final | ZR/NH/WDZ | Special properties |

American NEC Quick Reference

| Position | Code | Meaning |

|---|---|---|

| 1st | T/R/X | Insulation base |

| 2nd | H/blank | Heat rating |

| 3rd | H/W/blank | Additional property |

| 4th | N/blank | Jacket material |

| Suffix | -2 | Enhanced rating |

European IEC Quick Reference

| Position | Code | Meaning |

|---|---|---|

| 1st | H/A | Harmonized status |

| 2-3 | 03/05/07 | Voltage rating |

| 4th | V/R/S | Insulation |

| 5th | V/R/N | Sheath |

| 6th | -F/-U/-K | Flexibility |

| Final | G/X | Ground inclusion |

The Bottom Line: Decode Before You Order

Cable designation systems exist for good reason—they prevent costly mistakes and ensure safety compliance. Whether you're sourcing cables from China, specifying products to American standards, or working with European suppliers, taking the time to fully decode and understand cable designations saves money, prevents installation errors, and ensures regulatory compliance.

Before placing any cable order:

- Decode the complete designation character by character

- Verify voltage ratings match your application

- Confirm conductor size meets electrical requirements

- Check that insulation/sheath materials suit the environment

- Ensure required certifications are explicitly specified

The few minutes spent properly decoding a cable specification can prevent weeks of delays, thousands in rejected orders, and potential safety issues.

Pro tip: Keep a reference sheet of common designations in your preferred standard. After decoding 20-30 cables, pattern recognition kicks in and you'll read these codes as fluently as your native language.

Now stop guessing at cable specs—decode them properly, and order with confidence.