Catenary cable refers to a tensioned cable suspended between two points that supports its own weight and often the weight of other cables or equipment. The name comes from the mathematical curve—“catenary”—that such a hanging cable forms under gravity.

catenary cable

This type of cable is widely used in overhead support systems, aerial cable routing, railway power lines, and architectural tension structures.

🔍 What Is a Catenary Cable?

A catenary cable system typically consists of:

A high-tensile steel wire rope

Anchoring or tensioning components at both ends

Accessories like grippers, hangers, or clamps to suspend secondary elements (like electrical or communication cables)

Catenary cables do not sag like slack lines—instead, they are engineered to maintain shape and stability under tension, forming a predictable curve for support.

⚙️ Common Applications of Catenary Cable

| Application | Purpose |

|---|---|

| 🏗️ Building and Construction | Suspend lighting, ductwork, or signage across open spans |

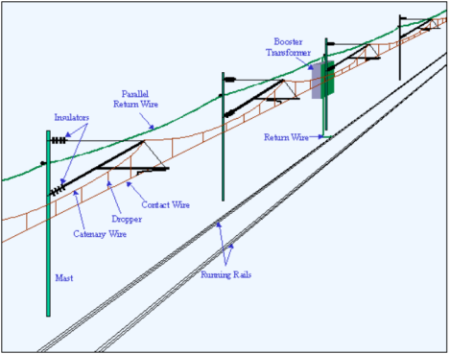

| 🚅 Railways | Overhead catenary wires transmit power to electric trains |

| 📡 Telecom & Power | Support messenger wire for hanging data or power cables |

| 🏟️ Architectural Design | Used in tensioned fabric structures and aesthetic frameworks |

| 💡 Industrial Facilities | Create cable support pathways in large, open areas |

| 🏕️ Outdoor Installations | Secure event tents, string lights, or camera lines |

🔩 Components of a Catenary Cable System

A basic catenary system may include:

Messenger wire (main catenary wire—usually galvanized or stainless steel)

Turnbuckles for adjusting tension

End anchors or eye bolts

Cable clamps

Drop wires or hooks to hang electrical/optical cables

📐 How to Design and Install a Catenary Cable System

Determine Span & Load: How far does the cable span, and how much weight will it carry?

Choose Cable Type: Use steel stranded cable or coated aircraft cable with adequate tensile strength

Anchor Securely: Ensure end-point structures can handle cable tension

Tension Properly: Use turnbuckles or tensioning tools for sag control

Install Cable Drops: Add intermediate hangers for supported cables or lights

Inspect Regularly: Check tension and fittings for wear or corrosion

🧪 Technical Specs of Common Catenary Cables

| Parameter | Typical Value |

|---|---|

| Material | Galvanized or stainless steel |

| Diameter | 3/32', 1/8', 3/16', 1/4' and up |

| Breaking Strength | Varies by gauge (e.g., 1/8' ≈ 2,000 lbs) |

| Coating | PVC, nylon, or bare steel |

| Standards | ASTM A475, A1023, UL, CSA, or ISO |

✅ Benefits of Catenary Cables

🛠️ Flexible installation over long distances

💪 Strong load-bearing capacity

💡 Clean, suspended support for electrical or lighting systems

🌧️ Weather-resistant when using coated steel cable

📏 Customizable length and tensioning

🧱 No need for multiple intermediate supports

📦 TOT Wire & Cable – Your Catenary Cable Supplier

Looking for high-quality catenary cable systems?

TOT Wire & Cable offers:

Galvanized & stainless steel messenger wires

Complete catenary cable kits with anchors, clamps & accessories

Custom cut-to-length cable spools

Tension-rated, corrosion-resistant solutions for indoor and outdoor use

👉 Request a Quote for your overhead cable support project today!