Commercial low voltage wiring encompasses structured cabling systems operating under 50 volts, including data networks, security systems, fire alarms, HVAC controls, and telecommunications infrastructure. These systems require specialized installation techniques, code compliance, and professional-grade components to ensure reliable operation in business environments.

commercial low voltage wiring

What is Commercial Low Voltage Wiring?

Commercial low voltage wiring refers to electrical systems that operate at less than 50 volts and are specifically designed for business applications. Unlike residential systems, commercial installations must meet stricter codes, support higher user densities, and provide enterprise-level reliability.

Common Commercial Low Voltage Systems

Data and Communications:

- Ethernet networks (Cat5e, Cat6, Cat6A)

- Fiber optic backbone systems

- Telephone and VoIP systems

- Wireless access point infrastructure

Security and Life Safety:

- IP security camera systems

- Access control systems

- Fire alarm and detection systems

- Emergency communication systems

Building Automation:

- HVAC control systems

- Lighting control networks

- Energy management systems

- Environmental monitoring

Audio/Visual Systems:

- Conference room AV systems

- Digital signage networks

- Public address systems

- Background music distribution

Code Requirements and Standards

National Electrical Code (NEC) Articles

Article 725: Class 1, 2, and 3 remote control circuits Article 760: Fire alarm systems Article 770: Optical fiber cables Article 800: Communications circuits Article 820: Community antenna television (CATV)

Industry Standards

TIA-568: Commercial building telecommunications cabling TIA-569: Commercial building pathways and spaces NFPA 72: National Fire Alarm and Signaling Code IEEE 802.3: Ethernet networking standards

Local Code Compliance

- Building permits required for most commercial installations

- Inspection requirements vary by jurisdiction

- Fire stopping and pathway requirements

- Accessibility compliance (ADA)

System Design Considerations

Structured Cabling Design

Horizontal Distribution:

- Maximum 90 meters from telecom room to work area

- Minimum Cat6 cable for new installations

- Dedicated pathways for different system types

- Proper cable management and labeling

Backbone Distribution:

- Fiber optic for high-speed data transmission

- Copper for lower-speed control systems

- Redundant pathways for critical systems

- Equipment room environmental controls

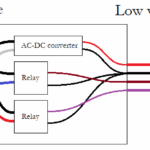

Power Requirements

Power over Ethernet (PoE):

- PoE+ (25.5W) for IP phones and basic devices

- PoE++ (60W-90W) for wireless access points and cameras

- High Power PoE (100W+) for lighting and large displays

Dedicated Low Voltage Power:

- 12V/24V DC systems for security and HVAC

- Uninterruptible power supplies (UPS) for critical systems

- Battery backup for life safety systems

Installation Methods and Materials

Cable Types and Applications

Category Cables:

- Cat5e: Basic data and voice (up to 1 Gigabit)

- Cat6: Enhanced performance (up to 10 Gigabit at 55m)

- Cat6A: Augmented performance (10 Gigabit at 100m)

- Cat8: High-speed data centers (25/40 Gigabit)

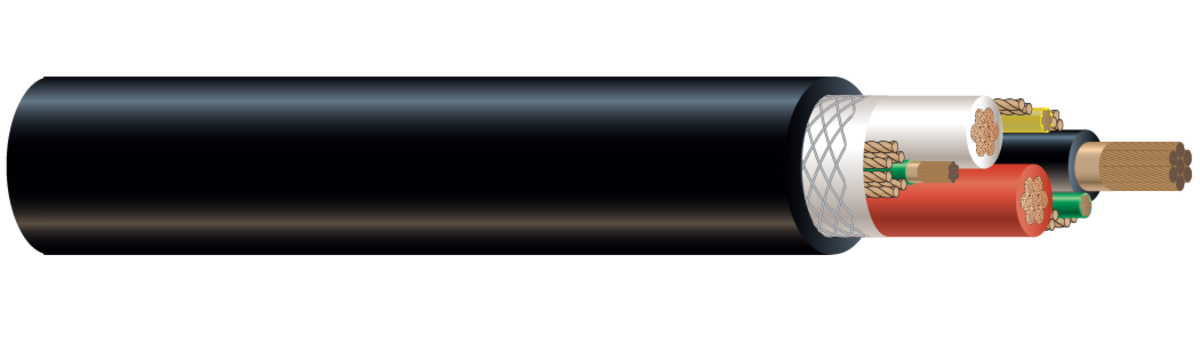

Fiber Optic Cables:

- Multimode: Short to medium distances (up to 550m)

- Singlemode: Long distance backbone (up to 40km)

- Indoor/outdoor rated: Based on installation environment

Specialized Cables:

- Fire alarm cable: FPLR/FPLP rated for life safety

- Security cable: Shielded for camera and access control

- Coaxial cable: Video distribution and broadband

Pathway Systems

Cable Tray Systems:

- Ladder tray for heavy cable loads

- Solid bottom tray for smaller cables

- Wire mesh tray for flexible installations

- Proper separation of power and low voltage

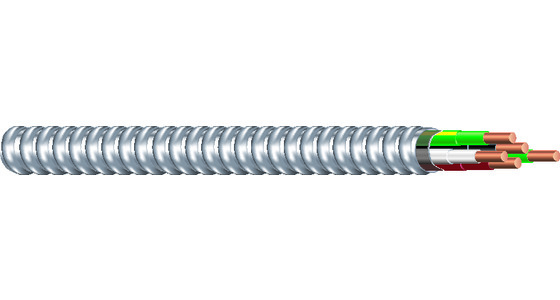

Conduit and Raceway:

- EMT conduit for mechanical protection

- Flexible conduit for short runs and connections

- Surface raceway for retrofit installations

- Plenum-rated pathways for air handling spaces

Termination and Connection Hardware

Network Infrastructure:

- 19-inch equipment racks and cabinets

- Patch panels for organized terminations

- Network switches and routers

- Cable management systems

Connection Components:

- RJ45 connectors and keystone jacks

- Fiber optic connectors (LC, SC, ST types)

- Punch-down blocks for telephone systems

- Coaxial connectors and splitters

Installation Best Practices

Planning and Design Phase

Site Survey Requirements:

- Existing infrastructure assessment

- Pathway availability analysis

- Power and HVAC considerations

- Future expansion planning

Documentation Standards:

- As-built drawings and cable schedules

- Testing and certification records

- Warranty and maintenance documentation

- User training materials

Installation Execution

Cable Installation:

- Proper cable pulling techniques to avoid damage

- Minimum bend radius requirements (4x cable diameter)

- Separation from power cables (minimum 2 inches)

- Fire stopping at floor and wall penetrations

Termination Quality:

- Professional-grade termination tools

- Consistent termination techniques

- Proper strain relief and cable support

- Testing each connection before final acceptance

Testing and Certification

Performance Testing:

- TIA-568 compliance testing for data cables

- Optical power testing for fiber installations

- Continuity and resistance testing for control systems

- Documentation of all test results

System Integration Testing:

- End-to-end system functionality

- Load testing for PoE systems

- Security system alarm verification

- Fire alarm system acceptance testing

Common Applications by Industry

Office Buildings

- Structured cabling for workstations

- Conference room AV systems

- Building access control

- HVAC and lighting controls

Healthcare Facilities

- Nurse call systems

- Medical equipment networks

- Security and monitoring systems

- Fire alarm and mass notification

Educational Institutions

- Classroom technology systems

- Campus-wide networking

- Security and access control

- Emergency communication systems

Retail Environments

- Point-of-sale networks

- Security camera systems

- Digital signage displays

- Background music systems

Manufacturing Facilities

- Industrial control networks

- Machine monitoring systems

- Safety and alarm systems

- Environmental controls

Maintenance and Troubleshooting

Preventive Maintenance

Regular Inspections:

- Visual inspection of connections and pathways

- Environmental monitoring of equipment rooms

- Battery testing for backup systems

- Software updates and security patches

Performance Monitoring:

- Network performance analysis

- Power consumption monitoring

- System error log review

- Capacity planning assessments

Common Issues and Solutions

Connectivity Problems:

- Cable damage from construction activities

- Loose connections due to vibration

- Environmental factors (moisture, temperature)

- Equipment failures and compatibility issues

Performance Degradation:

- Network congestion and bandwidth limitations

- Aging cable infrastructure

- Improper installation practices

- Electromagnetic interference

Cost Considerations

Initial Installation Costs

Material Costs:

- Cable and connectivity hardware (30-40%)

- Labor and installation services (40-50%)

- Testing and certification (5-10%)

- Documentation and training (5-10%)

Factors Affecting Cost:

- Building size and complexity

- Cable types and performance requirements

- Pathway availability and access

- Local labor rates and permit fees

Long-term Value

Total Cost of Ownership:

- Reduced maintenance with quality installation

- Scalability for future technology upgrades

- Energy efficiency with modern systems

- Improved productivity and reliability

Working with Contractors

Selecting Qualified Contractors

Required Certifications:

- BICSI certification for structured cabling

- Manufacturer certifications for specific systems

- State electrical contractor licenses

- Insurance and bonding requirements

Evaluation Criteria:

- Experience with similar projects

- Quality of previous installations

- Testing and documentation capabilities

- Ongoing support and maintenance services

Project Management

Contract Requirements:

- Detailed scope of work and specifications

- Testing and performance standards

- Warranty terms and conditions

- Project timeline and milestones

Quality Control:

- Regular progress inspections

- Material approval processes

- Testing verification procedures

- Final acceptance criteria

Future Considerations

Technology Trends

Emerging Standards:

- Wi-Fi 6E and 7 infrastructure requirements

- IoT device integration and management

- Power over Ethernet advancements

- Cybersecurity integration

Infrastructure Adaptability:

- Flexible pathway systems for future changes

- Scalable equipment room designs

- Convergence of building systems

- Cloud-based management platforms

Conclusion

Commercial low voltage wiring forms the backbone of modern business operations, requiring careful planning, professional installation, and ongoing maintenance. Success depends on understanding code requirements, selecting appropriate materials, and working with qualified contractors. Proper investment in low voltage infrastructure provides the foundation for reliable communications, security, and building automation systems that support business productivity and growth.

Whether upgrading existing facilities or planning new construction, prioritize quality components, professional installation, and comprehensive documentation to ensure your commercial low voltage systems meet current needs and support future technology evolution.