Understanding automotive wire color codes is crucial for anyone working on vehicle electrical systems. Whether you're a professional mechanic, DIY enthusiast, or automotive technician, knowing these color conventions can save time, prevent costly mistakes, and ensure safe electrical repairs.

automotive wire color code chart

What is an Automotive Wire Color Code Chart?

An automotive wire color code chart is a standardized reference system that identifies the function and purpose of electrical wires in vehicles based on their color. These color codes help technicians quickly identify circuits, trace electrical problems, and perform accurate repairs without extensive testing.

Standard Automotive Wire Color Codes

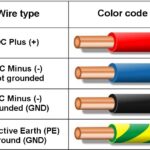

Primary Power and Ground Wires

Red Wires

- Battery positive connections

- Main power feeds

- Ignition switch power

- Starter motor connections

Black Wires

- Ground connections

- Negative battery terminals

- Chassis ground points

- Return circuits

Yellow Wires

- Left turn signals

- Some charging system connections

- Backup lights (in some systems)

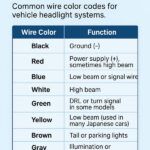

Lighting System Wire Colors

Brown Wires

- Tail lights

- Parking lights

- Dashboard illumination

- License plate lights

Blue Wires

- Headlight high beams

- Some antenna connections

- Electric fan circuits

White Wires

- Right turn signals

- Some backup light circuits

- Ground returns in certain systems

Green Wires

- Right turn signals (alternative)

- Some instrument panel circuits

- Backup lights

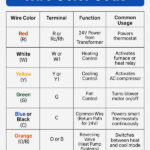

Ignition and Engine Management

Orange Wires

- Ignition system components

- Distributor connections

- Some fuel injection circuits

- Accessory power feeds

Purple/Violet Wires

- Ignition coil connections

- Some brake light circuits

- Accessory circuits

Pink Wires

- Ignition timing circuits

- Some fuel system components

- Electronic control modules

Accessory and Comfort Systems

Gray Wires

- Radio and audio systems

- Some interior lighting

- Accessory circuits

Tan/Beige Wires

- Clock circuits

- Some instrument connections

- Interior accessories

Regional and Manufacturer Variations

European Standards (DIN)

European vehicles often follow DIN (Deutsche Industrie Norm) color coding standards, which may differ from North American conventions. Common European color codes include:

- Brown: Positive power supply

- Blue: Headlight circuits

- Green/Yellow: Ground connections

- Black: General ground and negative connections

Asian Manufacturer Codes

Japanese and other Asian manufacturers may use unique color coding systems:

- Light Green: Often used for turn signals

- Light Blue: Air conditioning circuits

- Orange: Charging system connections

American Domestic Standards

Ford, General Motors, and Chrysler have historically used different color coding conventions:

Ford Color Codes:

- Light Blue: Windshield wipers

- Dark Blue: Headlight high beams

- Dark Green: Right turn signals

General Motors:

- Orange: Battery positive

- Purple: Accessory power

- Tan: Fuel injection systems

How to Use an Automotive Wire Color Code Chart

Step-by-Step Wire Identification

- Locate the wire you need to identify or work with

- Note the primary color and any secondary stripe colors

- Consult your vehicle's specific wiring diagram alongside the color chart

- Cross-reference with the manufacturer's service manual

- Test the circuit with a multimeter to confirm function

Safety Precautions

- Always disconnect the battery before working on electrical systems

- Use proper insulated tools

- Never assume wire function based solely on color

- Verify circuits with testing equipment

- Follow manufacturer-specific diagrams

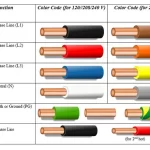

Common Wire Color Code Combinations

Striped Wire Meanings

Many automotive wires feature a primary color with a colored stripe, providing more specific identification:

- Red with White Stripe: Accessory power feed

- Black with Yellow Stripe: Ground with tracer

- Blue with White Stripe: Windshield wiper circuits

- Green with Red Stripe: Turn signal with brake light integration

Troubleshooting with Wire Color Codes

Identifying Electrical Problems

Understanding wire colors helps diagnose common electrical issues:

Turn Signal Problems:

- Check yellow (left) and green/white (right) turn signal wires

- Inspect connections at flasher relay and bulb sockets

Lighting Issues:

- Brown wires for tail/parking lights

- Blue wires for headlight high beams

- White wires for backup lights

Charging System Diagnosis:

- Red wires from alternator to battery

- Orange wires for ignition-switched power

- Black wires for ground connections

Tools for Working with Automotive Wiring

Essential Equipment

- Digital Multimeter: For voltage, current, and resistance testing

- Wire Strippers: For clean wire preparation

- Electrical Tape: For secure connections

- Heat Shrink Tubing: For professional wire repairs

- Wiring Diagrams: Vehicle-specific electrical schematics

Testing Procedures

- Continuity Testing: Verify wire integrity from end to end

- Voltage Testing: Confirm proper power supply levels

- Ground Testing: Ensure solid ground connections

- Load Testing: Check circuit performance under normal operation

Modern Vehicle Considerations

CAN Bus and Network Wiring

Modern vehicles use sophisticated communication networks that may not follow traditional color coding:

- Twisted Pair Wires: Often used for data communication

- Shielded Cables: Protect against electromagnetic interference

- Fiber Optic Cables: Used in high-end audio and communication systems

Hybrid and Electric Vehicle Wiring

Electric and hybrid vehicles introduce additional wire color considerations:

- Orange Wires: High-voltage DC systems (typically 12V+ systems)

- Blue Wires: High-voltage AC systems

- Yellow/Green: Safety ground connections

Best Practices for Wire Color Code Reference

Documentation and Record Keeping

- Always photograph wire connections before disconnection

- Keep manufacturer wiring diagrams readily available

- Document any non-standard color coding found

- Maintain a reference library of color charts for different manufacturers

Professional Tips

- Use a wire color code app for quick mobile reference

- Create custom color charts for frequently serviced vehicle models

- Stay updated on manufacturer bulletins regarding wiring changes

- Invest in quality testing equipment for accurate diagnosis

Conclusion

Mastering automotive wire color codes is essential for efficient and safe electrical system work. While standardized colors provide a general guide, always verify with manufacturer-specific documentation and proper testing procedures. Remember that wire colors are a starting point for identification, not a replacement for thorough electrical diagnosis.

Whether you're tracing a simple lighting circuit or diagnosing complex engine management systems, understanding these color conventions will improve your efficiency and accuracy. Keep this reference handy, stay updated on manufacturer-specific variations, and always prioritize safety when working with automotive electrical systems.

By following proper procedures and understanding these color code standards, you'll be better equipped to handle any automotive electrical challenge that comes your way.