What is a Power Cable?

A power cable is an electrical cable specifically designed to transmit electrical power from one location to another. Power cables consist of three major components: conductors, insulation, and protective jacket, with their construction determined by working voltage, current-carrying capacity, and environmental conditions. These cables serve as the backbone of electrical infrastructure, powering everything from household appliances to industrial machinery and entire electrical grids.

what is a power cable

Core Components of Power Cables

1. Conductors

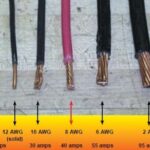

The heart of any power cable is its conductor, which carries the electrical current. Conductors are mainly made of copper or aluminum, with different classes including solid (Class 1), stranded (Class 2), flexible (Class 5), and extra flexible (Class 6) for specialized applications.

Material Options:

- Copper: Higher conductivity, more expensive, excellent for high-performance applications

- Aluminum: Cost-effective, lighter weight, suitable for most standard applications

2. Insulation

The insulation layer prevents electrical current from escaping and protects against short circuits. The thickness and type of insulation depend on the voltage rating and environmental requirements.

3. Protective Jacket

The outer jacket provides mechanical protection, weather resistance, and chemical protection based on the cable's intended environment and application.

Power Cable Classification by Voltage

Low Voltage (LV) Cables - Up to 1,000V

Low voltage cables (up to 1,000V) are used for industrial power installations, household wiring, and small appliances. These are the most common type of power cables found in residential and commercial settings.

Common Applications:

- Household electrical wiring

- Small appliances and electronics

- Office buildings and retail spaces

- Light industrial applications

Medium Voltage (MV) Cables - 1kV to 36kV

Medium voltage cables are used to distribute electricity from electrical substations to transformer stations. These cables handle higher power loads and are essential for power distribution networks.

Common Applications:

- Industrial facilities

- Large commercial buildings

- Municipal power distribution

- Substations and transformer connections

High Voltage (HV) Cables - Above 36kV

High voltage cables are used to transport electricity from generating plants to electrical substations. These represent the highest tier of power transmission infrastructure.

Common Applications:

- Power plant connections

- Long-distance power transmission

- Grid interconnections

- Major industrial facilities

Types of Power Cables by Application

1. Building Wire and Cable

The most common type for residential and commercial construction, typically including:

- NM Cable (Non-Metallic): Standard household wiring

- UF Cable (Underground Feeder): For buried applications

- MC Cable (Metal Clad): For commercial and industrial use

2. Flexible Power Cables

Portable cords have two or more conductors and are best suited for temporary supply applications requiring flexibility, with multiple jacket options for different environmental conditions.

Applications:

- Extension cords

- Appliance connections

- Temporary power supplies

- Mobile equipment

3. Armored Power Cables

Designed for harsh environments and underground installations:

- SWA (Steel Wire Armored): For underground and industrial use

- AWA (Aluminum Wire Armored): Lighter alternative to steel

- XLPE Insulated: For high-temperature applications

4. Submarine and Underwater Cables

Power cables are used for offshore platforms and subsea production equipment, such as control pods and electric pumps.

Power Cable Construction Types

Single Core vs Multi-Core

- Single Core: One conductor per cable, used for high-voltage applications

- Multi-Core: Multiple conductors in one cable, common for low and medium voltage

Solid vs Stranded Conductors

- Solid: Single wire conductor, less flexible but more durable

- Stranded: Multiple thin wires twisted together, more flexible

Selection Criteria for Power Cables

1. Electrical Requirements

- Voltage Rating: Must exceed system voltage

- Current Capacity: Based on load requirements

- Frequency: AC or DC applications

- Power Factor: For AC systems

2. Environmental Factors

Temperature rating ensures the cable can operate safely within the expected temperature range.

Key Considerations:

- Operating temperature range

- Moisture and water exposure

- Chemical resistance requirements

- UV radiation exposure

- Mechanical stress and vibration

3. Installation Requirements

- Flexibility: Bending radius and installation ease

- Size and Weight: Space constraints and support requirements

- Fire Resistance: Building code requirements

- EMI/EMC: Electromagnetic interference considerations

Common Power Cable Applications

Residential Applications

- Main service entrance cables

- Branch circuit wiring

- Appliance connections (ranges, dryers, air conditioners)

- Outdoor lighting and landscaping

- Swimming pool and spa wiring

Commercial Applications

- Office building power distribution

- Retail store electrical systems

- Restaurant and hospitality wiring

- Medical facility power systems

- Educational institution wiring

Industrial Applications

- Motor and machinery connections

- Control panel wiring

- Process equipment power

- Emergency and backup power systems

- Hazardous location wiring

Infrastructure Applications

- Utility power distribution

- Street lighting systems

- Traffic signal power

- Telecommunications facility power

- Transportation system electrification

Installation and Safety Considerations

Professional Installation Requirements

Power cable installation should typically be performed by qualified electricians due to:

- Safety risks associated with electrical power

- Local electrical code compliance

- Proper sizing and protection requirements

- Inspection and permitting needs

Safety Guidelines

- Always de-energize circuits before work

- Use appropriate personal protective equipment

- Follow National Electrical Code (NEC) requirements

- Ensure proper grounding and bonding

- Install appropriate overcurrent protection

Maintenance and Troubleshooting

Regular Inspection Points

- Visual inspection for damage or wear

- Connection tightness and condition

- Insulation resistance testing

- Temperature monitoring under load

- Ground fault and continuity testing

Common Issues

- Overheating: Often due to overloading or poor connections

- Insulation Breakdown: From age, moisture, or overvoltage

- Mechanical Damage: From improper installation or external forces

- Corrosion: In connections and terminations

Future Trends in Power Cable Technology

Smart Cable Technology

- Integrated sensors for monitoring

- Real-time condition assessment

- Predictive maintenance capabilities

- Communication integration

Sustainable Materials

- Environmentally friendly insulation materials

- Recyclable conductor materials

- Reduced environmental impact manufacturing

High-Performance Applications

- Superconducting cables for high-efficiency transmission

- Higher temperature ratings for compact installations

- Improved fire resistance and safety features

Cost Considerations

Factors Affecting Price

- Conductor material and size

- Insulation type and thickness

- Protective features (armoring, shielding)

- Certification and compliance requirements

- Market conditions and availability

Total Cost of Ownership

Consider not just initial purchase price but also:

- Installation costs

- Maintenance requirements

- Energy efficiency

- Lifespan and reliability

- Replacement and upgrade costs

Conclusion

Power cables are fundamental components of modern electrical infrastructure, enabling the safe and efficient transmission of electrical energy across countless applications. Understanding the different types, specifications, and selection criteria helps ensure optimal performance, safety, and cost-effectiveness in any electrical project.

Whether you're planning a residential renovation, designing a commercial facility, or managing industrial operations, choosing the right power cable requires careful consideration of electrical requirements, environmental conditions, and safety standards. When in doubt, consulting with qualified electrical professionals ensures proper selection, installation, and compliance with applicable codes and regulations.

The ongoing evolution of power cable technology continues to improve efficiency, safety, and environmental sustainability, making these essential components even more reliable and versatile for future electrical infrastructure needs.