Understanding US electrical wire color codes is essential for safe electrical work, code compliance, and proper system maintenance. This comprehensive guide covers the National Electrical Code (NEC) standards and common practices used throughout the United States.

Overview of US Electrical Wire Color Codes

The National Electrical Code (NEC), published by the National Fire Protection Association (NFPA), establishes the foundation for electrical wire color coding in the United States. These standards ensure consistency, safety, and proper identification across all electrical installations.

us electrical wire color code

Standard US Wire Color Codes by Voltage and Application

120V/240V Residential Systems

Hot Wires (Line/Live)

- Black: Primary hot wire in 120V circuits, Line 1 in 240V systems

- Red: Secondary hot wire in 240V circuits, switched hot in some applications

- Blue: Additional hot wire in multi-wire branch circuits

- Brown: Hot wire in 277V/480V commercial systems (when used in residential)

Neutral Wires

- White: Grounded neutral conductor in most applications

- Gray: Alternative neutral wire color, often used in commercial applications

Ground Wires

- Green: Equipment grounding conductor

- Green with Yellow Stripe: Equipment grounding conductor (alternative)

- Bare Copper: Equipment grounding conductor (uninsulated)

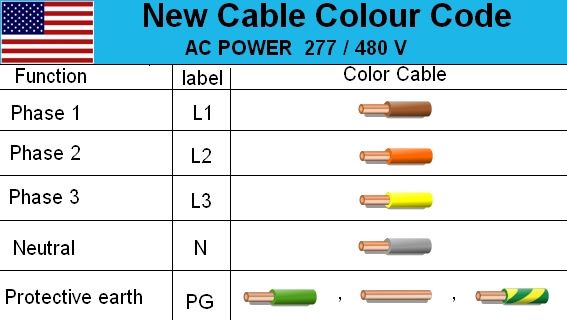

277V/480V Commercial and Industrial Systems

Hot Wires

- Brown: Phase A (Line 1)

- Orange: Phase B (Line 2)

- Yellow: Phase C (Line 3)

- Gray: Neutral conductor

- Green or Bare: Equipment grounding conductor

High Voltage Systems (Over 600V)

High Voltage Conductors

- Brown: Phase A

- Orange: Phase B

- Yellow: Phase C

- White or Gray: Neutral (if present)

- Green: Equipment grounding conductor

Detailed Wire Color Applications

Residential Wiring Color Codes

Standard 120V Circuits

- Black Wire: Hot wire carrying 120V from panel to outlets, switches, and fixtures

- White Wire: Neutral wire returning current to electrical panel

- Green/Bare Wire: Safety ground connecting to electrical boxes and equipment

240V Circuits (Electric Range, Dryer, AC Units)

- Black Wire: Hot wire #1 (120V to neutral, 240V between hot wires)

- Red Wire: Hot wire #2 (120V to neutral, 240V between hot wires)

- White Wire: Neutral wire (required for appliances needing 120V and 240V)

- Green/Bare Wire: Equipment grounding conductor

Three-Way Switch Circuits

- Black Wire: Common terminal connection

- Red Wire: Traveler wire between switches

- White Wire: Traveler wire or neutral (must be properly identified)

- Green/Bare Wire: Equipment grounding conductor

Commercial and Industrial Applications

Lighting Circuits (277V)

- Brown Wire: Hot conductor from panel

- Gray Wire: Neutral conductor

- Green Wire: Equipment grounding conductor

Motor Circuits

- Brown, Orange, Yellow: Three-phase power conductors

- Gray: Neutral (when required)

- Green: Equipment grounding conductor

- Red: Control circuit power

- Blue: Control circuit neutral

Special Purpose Wire Colors

Control and Signal Wiring

Low Voltage Control Circuits

- Red: 24V power supply positive

- Blue: 24V power supply negative/neutral

- Yellow: Thermostat heating control

- Green: Thermostat cooling control

- White: Common control wire

- Orange: Reversing valve control (heat pumps)

Fire Alarm Systems

- Red: Power supply positive

- Black: Power supply negative

- Yellow: Notification appliance circuits

- Blue: Initiating device circuits

Security Systems

- Red: Power positive

- Black: Power negative

- Green: Data positive

- White: Data negative

- Yellow: Tamper circuits

Communication and Data Wiring

Ethernet/Network Cables (Cat5e/Cat6)

- White/Orange: Transmit positive

- Orange: Transmit negative

- White/Green: Receive positive

- Blue: Unused pair 1

- White/Blue: Unused pair 1

- Green: Receive negative

- White/Brown: Unused pair 2

- Brown: Unused pair 2

NEC Requirements and Code Compliance

Mandatory Color Coding Requirements

Article 200 - Grounded Conductors

- White or gray insulation required for grounded conductors

- Identification required at termination points

- Re-identification allowed in certain circumstances

Article 250 - Grounding and Bonding

- Green insulation or bare copper for equipment grounding conductors

- Green with yellow stripe acceptable alternative

- Proper bonding and grounding requirements

Article 210 - Branch Circuits

- Proper identification of ungrounded conductors

- Multi-wire branch circuit requirements

- AFCI and GFCI protection requirements

Identification and Marking Requirements

Conductor Identification Methods

- Colored insulation (preferred method)

- Colored tape at termination points

- Tags or labels for identification

- Paint marking (limited applications)

Re-identification Rules

- White wire can be re-identified as hot with colored tape

- Minimum #6 AWG and larger conductors

- Clear marking at both ends required

- Documentation in electrical panel

Common Wiring Mistakes and Code Violations

Frequent Color Code Errors

Incorrect Neutral Usage

- Using white wire as hot conductor without proper re-identification

- Mixing neutrals between different circuits

- Improper multi-wire branch circuit installation

Grounding Violations

- Using ground wire as neutral

- Improper equipment bonding

- Missing equipment grounding conductors

Switch Loop Wiring Issues

- Improper use of white wire in switch loops

- Missing neutral conductors at switch locations

- Inadequate conductor identification

Testing and Verification Procedures

Electrical Testing Methods

Voltage Testing

- Use non-contact voltage testers for initial safety checks

- Digital multimeters for precise voltage measurements

- Always test known live circuit first

Continuity Testing

- Verify proper conductor connections

- Check for opens or shorts in circuits

- Confirm proper grounding connections

Polarity Testing

- Ensure hot and neutral are properly connected

- Verify proper three-way switch wiring

- Check outlet wiring orientation

Safety Procedures

Before Working on Electrical Systems

- Turn off power at circuit breaker

- Test circuits with voltage tester

- Lock out/tag out electrical panels

- Use appropriate personal protective equipment

- Follow OSHA electrical safety standards

Modern Electrical System Considerations

Smart Home and Automation Wiring

Smart Switch Requirements

- Neutral wire required for most smart switches

- Communication wiring for networked devices

- Power over Ethernet (PoE) applications

Home Automation Protocols

- Z-Wave and Zigbee wireless protocols

- Insteon powerline communication

- KNX/EIB bus systems

Renewable Energy Systems

Solar Panel Wiring

- Red and Black: DC positive and negative

- White: AC neutral from inverter

- Green: Equipment grounding

- Rapid shutdown device wiring

Battery Storage Systems

- Specific manufacturer color coding

- High voltage DC safety requirements

- Monitoring and control wiring

Regional and Local Code Variations

State and Local Amendments

Common Local Modifications

- Additional GFCI requirements

- Enhanced grounding standards

- Specific material requirements

- Inspection and permitting procedures

Jurisdiction-Specific Requirements

- Check with local electrical inspector

- Review local code amendments

- Understand permit requirements

- Follow local inspection procedures

Professional Installation Guidelines

Best Practices for Electricians

Planning and Design

- Create detailed wiring diagrams

- Plan wire routing and connections

- Calculate electrical loads properly

- Consider future expansion needs

Installation Quality

- Use appropriate wire sizes and types

- Make secure electrical connections

- Provide proper conductor support

- Label circuits clearly in electrical panel

Documentation and Inspection

- Maintain installation records

- Photograph complex wiring configurations

- Schedule required electrical inspections

- Provide system documentation to owners

Troubleshooting Common Electrical Issues

Systematic Diagnosis Approach

Circuit Problems

- Check circuit breaker status

- Test voltage at panel and outlets

- Verify wire connections and condition

- Check for overloaded circuits

Ground Fault Issues

- Test GFCI outlets and breakers

- Check for moisture or damaged insulation

- Verify proper equipment grounding

- Inspect outdoor and bathroom circuits

Conclusion

Understanding US electrical wire color codes is fundamental to safe and code-compliant electrical work. Whether you're a professional electrician, contractor, or informed homeowner, following NEC standards and local code requirements ensures electrical system safety and reliability.

Always remember that electrical work can be dangerous and may require professional installation and local permits. When in doubt, consult with a licensed electrician and your local electrical inspector to ensure proper installation and code compliance.

Stay current with NEC updates, local code amendments, and manufacturer recommendations to maintain the highest standards of electrical safety and performance in all your electrical projects.

5 comments

Best pre K homeschool curriculum 2022 07/30/2025

Hi there! I just would like to give you a big thumbs up for the excellent information you've got here on this post. I am returning to your website for more soon.

25 Major Pros & Cons Of Preschool – Dark night 08/30/2025

This is a good tip especially to those fresh to the blogosphere. Simple but very precise info… Thanks for sharing this one. A must read post!

Gutter cleaning 09/14/2025

Nice post. I was checking constantly this blog and I am impressed! Very helpful information particularly the last part :) I care for such info much. I was seeking this certain info for a long time. Thank you and best of luck.

Kidsontheyard 09/19/2025

I'm very pleased to uncover this page. I want to to thank you for ones time for this particularly fantastic read!! I definitely savored every bit of it and i also have you saved to fav to see new information on your blog.

Garage door repair services 09/23/2025

Hi! I simply wish to offer you a big thumbs up for the great info you have got here on this post. I am returning to your website for more soon.