Copper is one of the most widely used conductors in electrical wiring, prized for its low resistance and excellent conductivity. But even copper has resistance — and understanding copper wire resistance is critical for electrical engineers, electricians, and anyone working with wiring systems.

copper wire resistance

In this article, we explain what copper wire resistance is, how it affects performance, and how to calculate it for different wire sizes and lengths.

🔌 What Is Copper Wire Resistance?

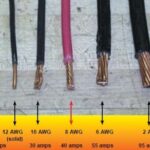

Resistance is a measure of how much a material opposes the flow of electric current. Even a good conductor like copper has some resistance, which increases with:

Longer wire length

Smaller wire diameter (gauge)

Higher temperature

Copper has a resistivity of about 1.68 × 10⁻⁸ ohm·meters at 20°C, making it ideal for low-resistance applications.

⚡ Why Does Copper Wire Resistance Matter?

Even small amounts of resistance can impact:

🔋 Voltage drop over long distances

🔥 Heat generation in high-current circuits

💡 Power loss in energy transmission

⚠️ Safety in undersized or overloaded wires

In high-voltage or long-distance wiring (like industrial or underground cables), knowing the wire’s resistance helps ensure efficient, safe operation.

🧮 How to Calculate Copper Wire Resistance

Use this basic formula:

R=ρ×LAR = \rho \times \frac{L}{A}

Where:

RR = resistance (ohms)

ρ\rho = copper resistivity (~1.68 × 10⁻⁸ Ω·m)

LL = length of the wire (in meters)

AA = cross-sectional area of the wire (in m²)

Or, use the resistance per unit length tables available for AWG sizes:

| Wire Size (AWG) | Ohms per 1000 ft (20°C) |

|---|---|

| 14 AWG | 2.525 Ω |

| 12 AWG | 1.588 Ω |

| 10 AWG | 0.999 Ω |

| 8 AWG | 0.628 Ω |

| 6 AWG | 0.395 Ω |

| 4 AWG | 0.248 Ω |

| 2 AWG | 0.156 Ω |

📌 Example:

If you run 100 ft of 12 AWG copper wire, the total resistance (round trip) is:

1.588 Ω/1000ft×200ft=0.3176 Ω1.588 \, \Omega/1000ft × 200ft = 0.3176 \, \Omega

🌡️ Temperature and Resistance

As temperature rises, copper’s resistance increases. The temperature coefficient of resistance for copper is about +0.00393 per °C. For example:

At 20°C → base resistance

At 60°C → ~16% more resistance

At 90°C → ~27% more resistance

This is why ampacity ratings differ depending on temperature insulation class (e.g., THW vs THHN wire).

🛠️ How to Reduce Copper Wire Resistance in Your System

Use thicker wires for longer runs

Avoid unnecessary splices or bends

Keep conductors cool and well ventilated

Choose low-resistance copper conductors like stranded or high-purity copper

✅ Applications Where Resistance Matters Most

Solar power systems

EV charging stations

Industrial control panels

Underground power distribution

Marine and automotive wiring

In these systems, voltage drop can mean loss of power, safety risks, or even equipment failure.

📦 Looking for Low-Resistance Copper Wire?

At TOT Wire & Cable, we supply a wide range of THW, THHN, VVR, and industrial copper cables made with high-purity copper and low resistance, suitable for both residential and industrial use.

👉 Contact us to request specs, pricing, or bulk orders.

📘 Frequently Asked Questions (FAQ)

Q: Does stranded copper wire have more resistance than solid?

A: Slightly, yes. Stranded wire has more surface area and small air gaps, but the difference is usually minimal for most applications.

Q: Can resistance affect motor performance?

A: Yes. Excess resistance causes voltage drop, which may reduce motor torque or lead to overheating.

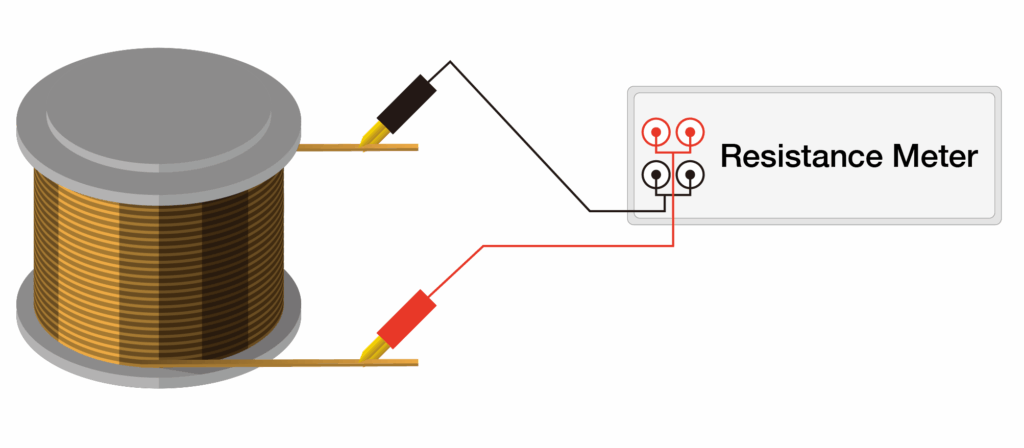

Q: How do I check copper wire resistance?

A: Use a precision multimeter to measure resistance across known lengths. Ensure wire is at room temperature for accurate readings.