In semiconductor packaging, the choice of bonding wire material is a critical decision that impacts a product's performance, reliability, and cost. While several materials are used, the three most common are gold, copper, and aluminum.

Each of these materials has unique properties that make it suitable for different applications. Understanding their trade-offs is key to selecting the right one for a specific design.

A Closer Look at Each Bonding Wire

Gold Bonding Wire: The High-Reliability Standard

For decades, gold bonding wire was the dominant material in the industry. Its benefits are clear:

- Process Stability: Gold doesn't oxidize during bonding, leading to a wide process window and high yield.

- High Reliability: Gold bonds are corrosion-resistant and highly reliable over time, making them ideal for mission-critical applications where failure is not an option.

However, the high cost of gold has driven the industry to seek more economical alternatives.

Copper Bonding Wire: The Cost-Effective Alternative

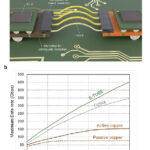

As gold prices have risen, copper bonding wire has quickly become a popular choice.

- Cost Advantage: The price of copper is significantly lower than gold, which drastically reduces manufacturing costs for mass-produced goods.

- Performance Edge: Copper has better electrical and thermal conductivity than gold and higher mechanical strength, which helps prevent wire sag or deformation during the molding process.

The main challenge with copper is its susceptibility to oxidation. The bonding process must be performed in an inert gas environment (such as nitrogen or argon) to prevent the formation of oxides, which would weaken the bond.

Aluminum Bonding Wire: The Power Expert

Aluminum bonding wire is often used in high-power semiconductor devices.

- Low Cost: Aluminum is a very low-cost material, making it attractive for large-scale, cost-sensitive power applications.

- High Hardness: Aluminum wire is stiffer than gold and copper, which allows for more consistent bonds on large, flat pads, especially in devices with high current flow.

However, aluminum bonding requires more ultrasonic power and pressure, which can potentially damage the underlying chip. Also, when an aluminum wire is bonded to a gold pad, a brittle intermetallic compound (often called 'purple plague') can form over time, which can lead to bond failure.

Conclusion

When choosing a bonding wire, there is no single 'best' material, only the one that is 'best for the application.' Gold remains the top choice for high-reliability products due to its superior performance and stability. Copper has become the go-to for mainstream consumer electronics because of its excellent balance of cost and performance. And aluminum holds its place in high-power applications, where its low cost and specific mechanical properties are a major advantage.