When working with heating elements, whether in industrial furnaces, ovens, or custom DIY heating projects, high temp wire is a critical component that ensures both safety and reliable performance. Choosing the right high temperature wire for heating elements isn’t just about heat resistance — it’s about matching the wire’s electrical and thermal properties to your specific application.

high temp wire for heating elements

🔧 Why Heating Elements Require High Temp Wire

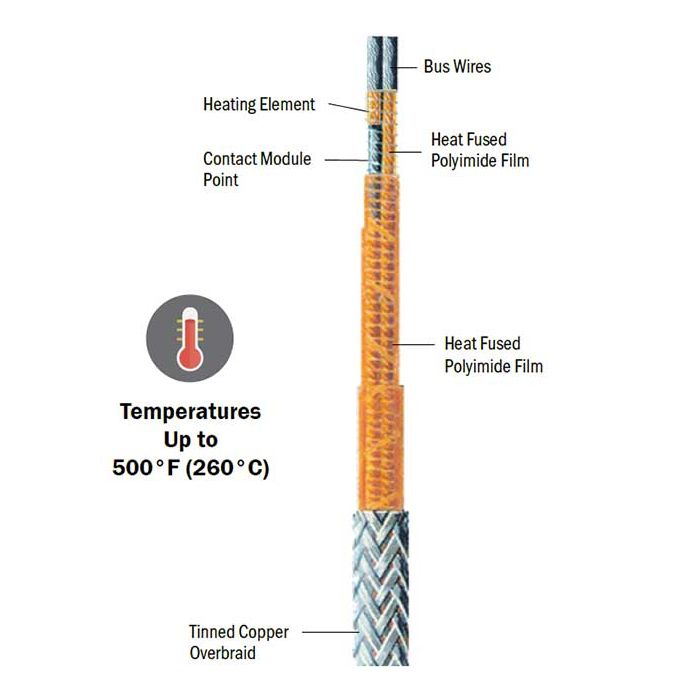

Heating elements are designed to reach very high temperatures, often exceeding 500°C (932°F). Using standard wire in these conditions can lead to insulation breakdown, short circuits, or even fire hazards. This is where high temp wire for heating elements becomes essential.

These wires are built with special insulation materials — like silicone rubber, PTFE (Teflon), mica, or fiberglass — that can withstand extreme heat without melting, degrading, or becoming brittle.

🔍 Key Properties to Look for

To select the right high temp wire for heating elements, consider the following:

Temperature Rating: Ensure the wire’s rating matches or exceeds the max temperature of your heating element (commonly 200°C–1000°C).

Voltage Rating: Match the system’s voltage (typically 300V or 600V).

Conductor Type: Solid or stranded copper, sometimes nickel or nichrome for extreme environments.

Flexibility: For tight or moving installations, flexible stranded wires are preferred.

Insulation Type:

Fiberglass: Withstands up to 482°C (900°F), used in kilns and industrial heaters.

Silicone: Flexible, heat-resistant up to 200°C–250°C.

PTFE: Chemically resistant and operates at up to 260°C.

⚙️ Common Applications

Electric ovens and toasters

Kilns and furnaces

Cartridge and tubular heaters

Industrial dryers

Laboratory heating systems

Heated tools or welding equipment

🛠 Examples of High Temp Wire Types

| Wire Type | Max Temp | Insulation | Common Use |

|---|---|---|---|

| MGT Wire | 450°C | Mica + Glass | Furnaces, Kilns |

| TGGT Wire | 250°C | Teflon Glass | High-end ovens |

| SRML Wire | 200°C–250°C | Silicone | Appliances, heaters |

| Fiberglass Wire | 482°C | Braided Glass | Industrial heating |

🧰 Installation Tips

Avoid sharp bends to prevent insulation damage

Use proper connectors rated for high temperature

Secure wire routing away from moving parts or open flames

Regularly inspect wires in high-heat environments for signs of wear

💬 Final Thoughts

Choosing the right high temp wire for heating elements ensures your heating system runs safely and efficiently. Whether you're wiring an industrial furnace or building a custom heat tool, proper wire selection is a foundational step. At TOT Wire & Cable, we offer a wide range of high temperature wires in various gauges and insulation types — with factory-direct pricing and expert support.

📞 Need Help Choosing the Right Wire?

Contact TOT Wire & Cable today for product guidance, pricing, or samples.