MGT Cable: Your Ultimate Guide & Product Selection

Are you looking for high-quality MGT cable for your marine electrical system? Our MGT cable products are designed for superior performance and longevity in the harshest marine environments.

We offer a full range of marine-grade tinned cables, all available for immediate delivery. Contact us today for a professional quote.

What is MGT Cable?

MGT cable, which stands for Marine Grade Tinned cable, is a specialized marine electrical cable designed specifically for harsh marine environments where corrosion resistance and reliability are critical. These marine-grade cables feature tinned copper conductors that provide superior protection against saltwater corrosion, making them the preferred choice for boats, yachts, offshore platforms, and coastal installations.

The tinned copper construction of MGT cables ensures long-lasting performance in marine applications where standard copper cables would quickly deteriorate due to salt spray, humidity, and corrosive marine atmospheres.

MGT Cable Construction and Features

MGT Cable Construction and Features

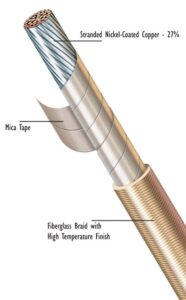

Tinned Copper Conductors

The core of every MGT cable consists of high-quality copper conductors that have been hot-dip tinned with pure tin. This tin coating process creates a protective barrier that prevents copper oxidation and corrosion, significantly extending cable life in marine environments.

Benefits of Tinned Copper:

- Superior corrosion resistance in saltwater environments

- Enhanced solderability for reliable connections

- Improved conductivity retention over time

- Resistance to galvanic corrosion

Marine Grade Insulation

MGT cables utilize specialized insulation materials designed to withstand marine conditions. Common insulation types include:

- Cross-Linked Polyethylene (XLPE): Provides excellent moisture resistance and temperature stability

- PVC Marine Grade: Offers flexibility and chemical resistance for marine applications

- Thermoplastic Elastomer (TPE): Combines flexibility with superior environmental resistance

Protective Jacketing

The outer jacket of marine-grade tinned cables provides the first line of defense against environmental factors. These jackets are formulated to resist:

- UV radiation from sunlight

- Oil and fuel contamination

- Abrasion and mechanical damage

- Temperature extremes

- Saltwater exposure

Types of MGT Cables

Single Conductor MGT Cable

Single conductor marine-grade tinned cables are ideal for simple point-to-point wiring applications in boats and marine equipment. Available in various gauges from 18 AWG to 4/0 AWG, these cables provide flexibility in marine electrical system design.

Multi-Conductor MGT Cable

Multi-conductor MGT cables contain multiple tinned copper conductors within a single jacket, making them perfect for control circuits, instrumentation, and complex marine electrical systems requiring multiple connections.

Duplex and Triplex MGT Cable

Duplex (two-conductor) and triplex (three-conductor) configurations offer convenient solutions for DC power distribution, battery charging circuits, and three-phase marine applications.

Armored MGT Cable

For applications requiring additional mechanical protection, armored MGT cables feature steel wire armor beneath the outer jacket, providing enhanced protection against physical damage in demanding marine installations.

Marine Cable Standards and Certifications

ABYC Standards

The American Boat and Yacht Council (ABYC) sets standards for marine electrical installations. MGT cables meeting ABYC E-11 standards ensure compliance with marine safety requirements and optimal performance in boat electrical systems.

USCG Approval

United States Coast Guard approved MGT cables meet stringent safety requirements for commercial marine applications, ensuring reliability in critical marine electrical systems.

ISO Marine Standards

International Organization for Standardization (ISO) marine cable standards, including ISO 13297, specify requirements for marine electrical cables used in pleasure craft and commercial vessels.

UL Marine Listings

Underwriters Laboratories (UL) marine cable listings provide assurance that MGT cables meet recognized safety standards for marine electrical applications.

Applications of MGT Cables

Boat Electrical Systems

Marine-grade tinned cables are essential for all boat electrical systems, including:

- DC power distribution from batteries to equipment

- Navigation lighting circuits

- Bilge pump wiring

- Engine control systems

- Communication equipment connections

Yacht Installations

Luxury yachts require reliable electrical systems for comfort and safety. MGT cables provide the durability needed for:

- Sophisticated entertainment systems

- Climate control wiring

- Galley equipment connections

- Deck lighting installations

- Generator and shore power systems

Commercial Marine Vessels

Commercial fishing boats, cargo ships, and passenger vessels rely on MGT cables for:

- Critical navigation equipment

- Safety system wiring

- Cargo handling equipment

- Emergency power systems

- Communication networks

Offshore Platforms

Oil rigs and offshore wind farms utilize marine-grade tinned cables for:

- Power distribution systems

- Control and instrumentation circuits

- Emergency shutdown systems

- Communication networks

- Environmental monitoring equipment

Dock and Marina Installations

Waterfront facilities use MGT cables for:

- Dock power pedestals

- Lighting systems

- Pump stations

- Security equipment

- Shore power connections

Installation Best Practices

Proper Cable Routing

Marine cable installation requires careful attention to routing to prevent chafing, crushing, or exposure to excessive heat. Cables should be secured with appropriate clamps and protected from sharp edges.

Waterproof Connections

All connections in marine environments must be properly sealed using marine-grade terminals, heat shrink tubing, and waterproof connectors to prevent moisture intrusion.

Strain Relief

Proper strain relief prevents cable damage from vessel movement and vibration. Marine-grade strain reliefs should be used at all connection points and cable entries.

Cable Support

MGT cables require adequate support throughout their runs to prevent sagging and mechanical stress. Cable ties, clamps, and cable trays designed for marine use ensure proper installation.

MGT Cable Sizing and Selection

Current Capacity Considerations

Marine electrical systems operate in challenging environments that affect cable current-carrying capacity. Factors to consider include:

- Ambient temperature in engine rooms and enclosed spaces

- Cable bundling effects

- Voltage drop limitations for critical equipment

- Safety margins for marine applications

Voltage Drop Calculations

Proper cable sizing ensures adequate voltage reaches marine equipment. Voltage drop becomes critical in larger vessels with long cable runs and high-current applications.

Environmental Factors

Cable selection must account for specific marine environmental conditions:

- Temperature extremes in different vessel compartments

- Exposure to bilge water and moisture

- Chemical exposure from fuels and cleaning products

- UV exposure on deck installations

Maintenance and Inspection

Regular Visual Inspection

Marine cables should be inspected regularly for signs of:

- Jacket damage or cracking

- Corrosion at terminations

- Chafing from vessel movement

- Moisture intrusion at connections

- UV degradation on exposed cables

Electrical Testing

Periodic testing of marine electrical systems includes:

- Insulation resistance measurements

- Continuity testing

- Ground fault testing

- Voltage drop verification

- Load testing of critical circuits

Preventive Maintenance

Proactive maintenance of MGT cable installations includes:

- Cleaning terminals and connections

- Applying corrosion inhibitors

- Replacing damaged cable clamps

- Updating outdated installations

- Documenting system modifications

Advantages of MGT Cables Over Standard Cables

Corrosion Resistance

The primary advantage of marine-grade tinned cables lies in their superior corrosion resistance. While standard copper cables deteriorate rapidly in marine environments, tinned copper maintains conductivity and structural integrity.

Longevity

MGT cables typically last 3-5 times longer than standard cables in marine applications, providing better long-term value despite higher initial costs.

Reliability

Marine environments demand reliable electrical systems for safety and operational requirements. MGT cables provide the dependability needed for critical marine applications.

Compliance

Using properly rated MGT cables ensures compliance with marine electrical codes and insurance requirements, avoiding potential liability issues.

Cost Considerations and Value

Initial Investment

While MGT cables cost more than standard electrical cables, the investment pays dividends through:

- Reduced replacement frequency

- Lower maintenance costs

- Improved system reliability

- Compliance with marine standards

Total Cost of Ownership

The total cost of ownership for MGT cables includes:

- Initial cable cost

- Installation labor

- Maintenance requirements

- Replacement frequency

- Downtime costs

Insurance Benefits

Many marine insurance policies require or offer premium reductions for vessels wired with approved marine-grade cables, offsetting some of the initial cost difference.

Common MGT Cable Specifications

Wire Gauge Options

MGT cables are available in standard AWG sizes:

- 18 AWG to 14 AWG for light-duty applications

- 12 AWG to 8 AWG for medium-current circuits

- 6 AWG to 4/0 AWG for high-current applications

Voltage Ratings

Common voltage ratings for marine-grade tinned cables include:

- 600V for most marine applications

- 1000V for higher voltage systems

- 2000V for specialized marine equipment

Temperature Ratings

MGT cables typically offer temperature ratings of:

- 60°C for standard applications

- 75°C for moderate temperature environments

- 90°C for high-temperature marine applications

Installation Tools and Accessories

Marine-Grade Terminals

Proper termination of MGT cables requires marine-grade terminals featuring:

- Tinned copper construction

- Heat shrink insulation

- Adhesive-lined sealing

- Corrosion-resistant plating

Cable Protection

Protective accessories for MGT cable installations include:

- Split-loom tubing

- Cable armor

- Waterproof boots

- Strain reliefs

- Cable clamps

Installation Hardware

Marine electrical installations require specialized hardware:

- Stainless steel cable ties

- Corrosion-resistant clamps

- Waterproof junction boxes

- Marine-grade conduit

- Deck cable glands

Future Trends in Marine Cables

Advanced Materials

Ongoing development in marine cable technology focuses on:

- Improved insulation materials

- Enhanced UV resistance

- Better flexibility in cold conditions

- Reduced environmental impact

Smart Marine Systems

Integration of MGT cables with smart marine systems includes:

- Digital monitoring capabilities

- Predictive maintenance features

- Remote system diagnostics

- Integrated communication protocols

Environmental Considerations

Modern marine cable manufacturing emphasizes:

- Recyclable materials

- Reduced toxic emissions

- Sustainable production methods

- Compliance with environmental regulations

Troubleshooting Common MGT Cable Issues

Corrosion Problems

Despite tin coating, corrosion can occur due to:

- Damaged cable jackets allowing moisture entry

- Improper terminations

- Galvanic corrosion from dissimilar metals

- Excessive exposure to acidic conditions

Connection Failures

Common connection issues include:

- Loose terminals causing voltage drop

- Moisture intrusion at connections

- Thermal cycling causing expansion/contraction

- Vibration loosening connections

Insulation Breakdown

Insulation failures may result from:

- UV exposure exceeding material limits

- Chemical contamination

- Mechanical damage during installation

- Age-related material degradation

Conclusion

MGT cables represent the essential foundation for reliable marine electrical systems. Their tinned copper construction provides unmatched corrosion resistance in harsh marine environments, while specialized insulation and jacketing materials ensure long-term performance and safety.

When selecting marine-grade tinned cables, consider the specific application requirements, environmental conditions, and regulatory compliance needs. Proper installation, maintenance, and inspection practices maximize the benefits of MGT cables, ensuring safe and reliable marine electrical systems for years to come.

For marine applications where electrical system failure could compromise safety or operations, MGT cables provide the reliability and durability demanded by the challenging marine environment. Their superior performance characteristics make them an essential component of any properly designed marine electrical system.

Don't Risk Your Electrical System's Safety.

No matter your project's scale, from a single wire replacement to a complete vessel rewiring, choosing the right cable is critical.

Contact our team of experts today for a personalized consultation and a no-obligation quote. We'll help you select the perfect MGT cable solution to ensure the safety and longevity of your marine electrical system.