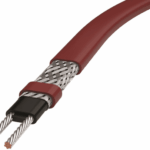

Mineral Insulated (MI) Heat Trace Cable is a robust, high-temperature electric heating cable used in industrial environments where extreme heat, mechanical protection, or fire resistance is required. Unlike conventional polymer-insulated trace cables, MI cable offers superior durability and consistent performance even in harsh, hazardous locations.

mineral insulated heat trace cable

This guide covers:

-

What MI heat trace cable is

-

Key features and construction

-

Applications and temperature ratings

-

Installation tips

-

Comparison with other trace cable types

📘 What Is Mineral Insulated Heat Trace Cable?

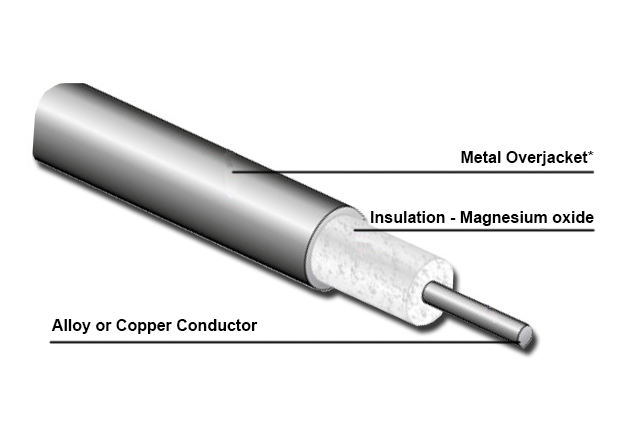

MI heat trace cable is a type of constant wattage electric heating cable made from a metal sheath (usually copper or stainless steel), tightly packed with magnesium oxide (MgO) insulation, and containing one or more resistance heating conductors.

Unlike self-regulating or polymer-based cables, MI cables:

-

Provide consistent power output

-

Operate at much higher temperatures

-

Resist mechanical damage, fire, and chemical exposure

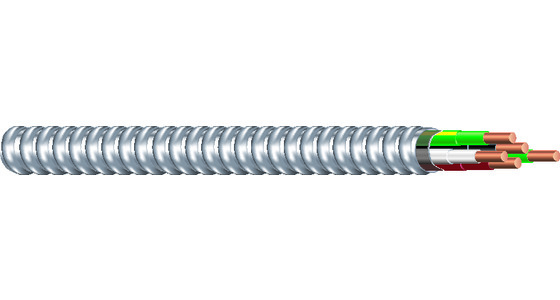

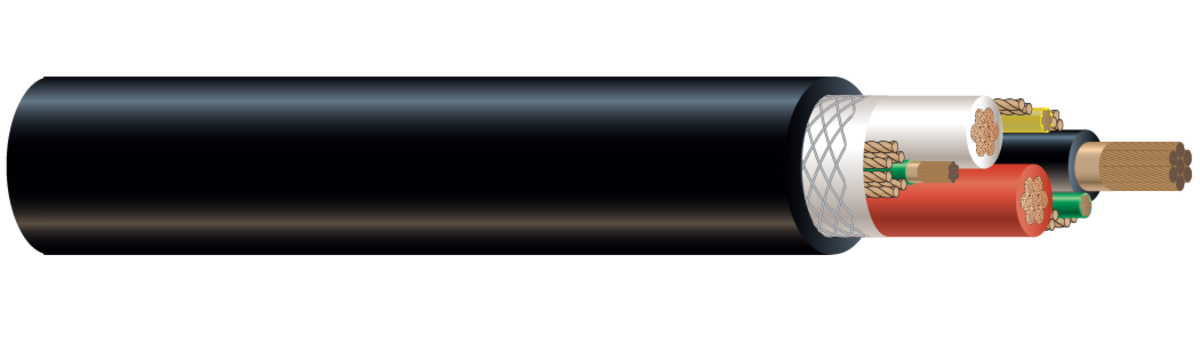

🧱 Construction of MI Heating Cable

| Component | Description |

|---|---|

| Outer Sheath | Copper, Alloy 825, or Stainless Steel for corrosion resistance and strength |

| Insulation | Compressed magnesium oxide (mineral) – inorganic, fireproof |

| Heating Conductor(s) | Nickel-chromium or copper resistance wires |

| Optional Jacket | PVC or LSZH outer covering for additional moisture or UV protection |

This rugged construction makes MI cables extremely reliable in critical process applications.

🌡️ Temperature Ratings

| Parameter | Rating |

|---|---|

| Continuous Exposure Temp | Up to +1000°C (sheath-limited) |

| Power Output | Typically 20–60 W/m |

| Voltage Rating | 120V / 240V / 277V / 480V |

| Ingress Protection | IP66/67 (with proper terminations) |

MI heat trace cables are ideal for maintaining or raising temperature on pipes and vessels in extreme environments.

🏭 Common Applications of MI Heat Trace Cables

| Industry | Application |

|---|---|

| Oil & Gas | Pipe freeze protection and viscosity control |

| Power Plants | Steam line temperature maintenance |

| Petrochemical Plants | High-temp process piping |

| Food & Beverage | Sanitary processing equipment |

| Fire Protection | Fire-rated cable for life safety circuits |

| Cryogenic Systems | Prevent condensation/frost buildup |

Key Benefit: Unaffected by high temperatures or corrosive chemicals, unlike polymer-insulated alternatives.

🛠️ Installation Considerations

-

Bend Radius: Limited due to the solid mineral core (typically ≥6x cable diameter)

-

Moisture Protection: MI cable must remain sealed; use approved glands/terminations

-

Fixing to Pipe: Use stainless steel ties or clips at recommended spacing

-

Power Distribution: Requires careful power planning due to constant wattage load

-

Heat Loss Calculations: Must be done in advance to determine required wattage per meter

Note: MI cables are not field-cuttable like self-regulating cables. They are pre-terminated or cut and sealed in factory or certified facility.

🆚 MI Heat Trace vs. Self-Regulating Cable

| Feature | MI Heat Trace Cable | Self-Regulating Cable |

|---|---|---|

| Power Output | Constant (e.g., 30 W/m) | Varies with ambient temperature |

| Temperature Limit | Up to 1000°C | Typically up to 150°C |

| Flexibility | Rigid | Very flexible |

| Field Cutting | No (requires factory termination) | Yes |

| Durability | Very high (mechanical & fire) | Moderate |

| Cost | Higher | Lower |

| Use Case | High-temp, critical systems | General pipe tracing, roofs |

📏 Sizing and Selection Guide

To select the right MI trace cable:

-

Determine pipe size, insulation type, and length

-

Calculate heat loss and wattage per meter

-

Choose MI cable with appropriate wattage (e.g., 30 W/m at 230V)

-

Ensure compatibility with hazardous area certifications (ATEX, IECEx, UL, etc.)

Optional accessories include:

-

Termination kits

-

Junction boxes

-

Temperature controllers

-

Insulation blankets

🔒 Certifications and Compliance

MI heat trace cables are typically certified for:

-

UL Listed / CSA / IECEx / ATEX

-

Hazardous Locations (Class I, Division 1/2)

-

Fire Resistance / Circuit Integrity (per IEC 60331 or UL 2196)

-

IP66/IP67 Enclosure Ratings

🧾 FAQs

Q: Can mineral insulated heat trace cable be used outdoors?

A: Yes, especially with a corrosion-resistant sheath like Alloy 825 and sealed terminations.

Q: Is MI cable safe for hazardous areas?

A: Absolutely. Many MI cables are certified for explosive atmospheres (e.g., Class I Div 1/2).

Q: Can MI cable be repaired in the field?

A: It’s not recommended. MI cable should be factory-terminated or replaced if damaged.

Q: How long does MI heat trace last?

A: Properly installed MI cables can last 20+ years, even in severe conditions.

✅ Conclusion

Mineral insulated heat trace cable is the gold standard for high-temperature, fire-resistant, and hazardous location applications. Its inorganic construction, mechanical strength, and thermal stability make it the best choice for critical infrastructure, even though it comes at a higher initial cost.

📞 Looking for MI Heat Trace Cable?

TOT Wire & Cable offers:

-

Custom-length MI heating cables

-

Stainless steel and Alloy 825 sheath options

-

UL/ATEX-certified solutions for industrial use

-

Factory-terminated and sealed kits

👉 Contact us today for a quote or technical advice on sizing and installation.