What is Rubberised Cable?

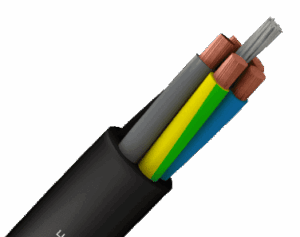

Rubberised cable, also known as rubber sheathed cable or rubber insulated cable, is a flexible electrical cable featuring rubber-based insulation and jacketing materials. These versatile cables are designed to provide superior flexibility, durability, and resistance to harsh environmental conditions, making them ideal for portable applications, industrial equipment, and demanding electrical installations.

The rubber construction of these cables offers exceptional performance in applications requiring frequent flexing, exposure to oils and chemicals, temperature extremes, and outdoor weather conditions. From construction sites to manufacturing facilities, rubberised cables deliver reliable power transmission where standard PVC cables would fail.

Rubberised Cable

Rubberised Cable Construction

Rubber Insulation Types

Modern rubberised cables utilize various rubber compounds optimized for specific applications:

EPDM Rubber (Ethylene Propylene Diene Monomer): Provides excellent weather resistance, ozone protection, and temperature stability. EPDM insulated cables are ideal for outdoor applications and harsh environmental conditions.

EPR (Ethylene Propylene Rubber): Offers superior electrical properties with good flexibility and chemical resistance. EPR rubber cables are commonly used in industrial and commercial applications.

Natural Rubber: Traditional rubber insulation providing excellent flexibility and electrical properties, though with limited chemical and weather resistance compared to synthetic alternatives.

Neoprene Rubber: Chloroprene rubber offers balanced performance with good oil resistance, flame retardancy, and mechanical durability for general-purpose applications.

Silicone Rubber: High-temperature rubber insulation capable of operating at extreme temperatures while maintaining flexibility and electrical integrity.

Conductor Materials

Rubberised cables feature various conductor options:

Stranded Copper Conductors: Provide excellent conductivity and flexibility for most rubber cable applications. Fine stranding enhances cable flexibility for portable applications.

Tinned Copper Conductors: Tin-plated copper offers enhanced corrosion resistance in harsh environments while maintaining excellent electrical properties.

Aluminum Conductors: Used in larger rubber cables where weight reduction is important, particularly for overhead installations and portable equipment.

Protective Sheathing

The outer sheath of rubberised cables provides environmental protection:

Heavy Duty Rubber Sheath: Multi-layer rubber construction offers maximum protection against mechanical damage, chemicals, and environmental factors.

Oil Resistant Sheath: Specialized rubber compounds resist petroleum products, hydraulic fluids, and industrial oils common in equipment applications.

Flame Retardant Sheath: Fire-resistant rubber formulations meet safety requirements for indoor installations and hazardous locations.

Types of Rubberised Cables

Flexible Rubber Cable

Flexible rubber cables are designed for applications requiring frequent movement:

- Portable tools and equipment

- Construction site wiring

- Temporary power installations

- Mobile machinery connections

- Entertainment and event lighting

These extra flexible cables feature fine-stranded conductors and soft rubber insulation optimized for repeated flexing without fatigue.

Heavy Duty Rubber Cable

Industrial-grade rubber cables built for demanding applications:

- Manufacturing equipment

- Mining machinery

- Marine installations

- Outdoor industrial systems

- Heavy construction equipment

Heavy duty construction includes reinforced insulation, armored protection options, and enhanced environmental resistance.

Welding Cable

Specialized rubber cables for welding applications:

- Arc welding equipment

- Resistance welding systems

- Plasma cutting equipment

- Industrial welding installations

- Portable welding operations

Welding cables feature extra-flexible construction with superior heat resistance and electrical performance for high-current applications.

Submersible Rubber Cable

Water-resistant cables for underwater and wet applications:

- Submersible pumps

- Underwater lighting

- Marine equipment

- Irrigation systems

- Water treatment facilities

These cables incorporate waterproof construction with specialized rubber compounds resistant to water absorption and degradation.

High Temperature Rubber Cable

Heat-resistant cables for extreme temperature applications:

- Industrial furnaces and ovens

- Heat treatment equipment

- Power generation facilities

- Chemical processing plants

- Automotive applications

High-temperature rubber insulation maintains flexibility and electrical integrity at elevated temperatures where standard cables would fail.

Applications of Rubberised Cables

Industrial Applications

Manufacturing and industrial facilities rely on rubber cables for:

- Motor connections requiring flexibility

- Portable equipment and tools

- Conveyors and material handling systems

- Process equipment with movement

- Emergency and backup power systems

Construction and Building

Construction sites use rubberised cables for:

- Temporary power distribution

- Portable tools and equipment

- Site lighting systems

- Concrete pumping equipment

- Tower cranes and lifting equipment

Marine and Offshore

Marine environments benefit from rubber cable properties:

- Boat and yacht electrical systems

- Offshore platform equipment

- Marine winches and deck machinery

- Underwater installations

- Port and harbor facilities

Entertainment and Events

Portable entertainment requires flexible cables:

- Stage and concert lighting

- Sound system connections

- Portable power distribution

- Temporary event installations

- Mobile broadcasting equipment

Agricultural Applications

Farm and agricultural equipment uses rubber cables for:

- Irrigation control systems

- Livestock facility equipment

- Mobile agricultural machinery

- Grain handling equipment

- Greenhouse installations

Advantages of Rubberised Cables

Superior Flexibility

The primary advantage of rubber insulated cables lies in their exceptional flexibility. Unlike rigid PVC cables, rubber cables maintain flexibility even in cold temperatures, making them ideal for portable applications and equipment with frequent movement.

Environmental Resistance

Rubber sheathed cables offer excellent resistance to:

- UV radiation and outdoor weathering

- Ozone and atmospheric pollutants

- Temperature extremes from -40°C to +90°C

- Moisture and humidity

- Oil and chemical exposure

Mechanical Durability

The tough rubber construction provides:

- Impact and crush resistance

- Abrasion resistance for dragging applications

- Tear resistance in demanding environments

- Fatigue resistance under repeated flexing

- Vibration resistance in machinery applications

Electrical Performance

Rubber insulation delivers:

- Excellent dielectric properties

- Low power factor for efficient transmission

- Good insulation resistance over time

- Stable electrical characteristics across temperature ranges

- Superior performance in high-frequency applications

Installation Guidelines

Handling and Storage

Proper handling ensures cable longevity:

- Avoid sharp bends below minimum bend radius

- Store in cool, dry conditions away from direct sunlight

- Protect from sharp objects and chemical spills

- Support cable weight to prevent stretching

- Inspect regularly for damage or deterioration

Installation Techniques

Professional installation practices include:

- Use appropriate cable pulling techniques

- Install proper strain relief at terminations

- Maintain minimum bend radius requirements

- Secure cables to prevent movement damage

- Provide adequate support for vertical runs

Connection Methods

Reliable connections require:

- Clean conductor preparation

- Proper terminal selection and crimping

- Appropriate insulation and sealing

- Strain relief at connection points

- Regular inspection and maintenance

Standards and Certifications

International Standards

Rubberised cables must comply with various international standards:

IEC 60245: International standard for rubber insulated cables for rated voltages up to and including 450/750V.

BS 6007: British standard specifying requirements for rubber insulated cables for electric power and lighting.

VDE 0250: German standard for rubber insulated flexible cables and cords.

UL 62: Underwriters Laboratories standard for flexible cords and cables in North America.

Industry Certifications

Quality certifications include:

- CE marking for European compliance

- CSA certification for Canadian markets

- UL listing for North American applications

- KEMA testing for European markets

- CCC certification for Chinese markets

Environmental Compliance

Modern rubber cables meet environmental requirements:

- RoHS compliance for restricted substances

- REACH regulation compliance

- Halogen-free formulations where required

- Recyclability considerations

- Low smoke and fume emissions

Selection Criteria

Electrical Requirements

Proper cable selection considers:

- Voltage rating and insulation class

- Current carrying capacity and conductor size

- Temperature rating for application environment

- Frequency response for AC applications

- Grounding and shielding requirements

Environmental Factors

Application environment assessment includes:

- Operating temperature range

- Chemical exposure potential

- Moisture and water resistance needs

- UV and weather exposure

- Mechanical stress and flexing requirements

Mechanical Properties

Physical performance requirements:

- Flexibility and bend radius

- Tensile strength and elongation

- Abrasion and tear resistance

- Impact and crush resistance

- Fatigue life under repeated flexing

Maintenance and Testing

Routine Inspection

Regular inspection prevents failures:

- Visual examination for cuts, cracks, or damage

- Flexibility testing for insulation degradation

- Connection integrity verification

- Environmental protection assessment

- Documentation of inspection results

Electrical Testing

Periodic electrical testing includes:

- Insulation resistance measurements

- Continuity testing of conductors

- Ground fault testing where applicable

- High-potential testing for critical applications

- Thermal testing under load conditions

Preventive Maintenance

Proactive maintenance extends cable life:

- Cleaning of connections and terminals

- Reapplication of protective coatings

- Replacement of damaged sections

- Upgrading support and protection systems

- Trending of test results over time

Common Issues and Troubleshooting

Insulation Degradation

Common causes and solutions:

- Ozone exposure requiring EPDM formulations

- UV degradation needing protective covers

- Chemical attack requiring resistant compounds

- Thermal aging requiring temperature control

- Mechanical damage requiring better protection

Flexibility Loss

Addressing stiffening issues:

- Cold temperature effects on rubber compounds

- Aging and oxidation of rubber materials

- Contamination affecting flexibility

- Improper storage and handling

- Selection of inappropriate rubber type

Connection Problems

Resolving connection failures:

- Corrosion at terminals and connections

- Thermal cycling effects on connections

- Mechanical stress at termination points

- Moisture ingress protection

- Proper strain relief installation

Cost Considerations

Initial Investment

Rubber cable costs include:

- Premium materials and manufacturing

- Specialized testing and certification

- Enhanced performance characteristics

- Quality construction and durability

- Compliance with industry standards

Lifecycle Value

Long-term benefits of rubber cables:

- Extended service life in harsh conditions

- Reduced maintenance and replacement costs

- Better performance and reliability

- Lower total cost of ownership

- Reduced downtime and operational disruptions

Application-Specific Economics

Cost analysis varies by application:

- Portable equipment requiring frequent replacement

- Fixed installations with long service life

- Harsh environments with high failure rates

- Critical applications where reliability is paramount

- Safety considerations and insurance implications

Environmental Considerations

Sustainable Manufacturing

Modern rubber cable production emphasizes:

- Reduced environmental impact

- Recyclable rubber compounds where possible

- Energy-efficient manufacturing processes

- Responsible sourcing of raw materials

- Compliance with environmental regulations

End-of-Life Management

Responsible disposal includes:

- Copper recovery from conductors

- Rubber recycling where facilities exist

- Proper disposal of non-recyclable components

- Minimizing landfill waste

- Environmental impact assessment

Future Trends and Innovations

Advanced Rubber Compounds

Ongoing development focuses on:

- Improved temperature resistance

- Enhanced flexibility at low temperatures

- Better chemical and oil resistance

- Reduced environmental impact

- Increased electrical performance

Smart Cable Technology

Integration of monitoring capabilities:

- Temperature sensing within cables

- Insulation condition monitoring

- Mechanical stress detection

- Wireless communication integration

- Predictive maintenance alerts

Sustainability Initiatives

Environmental considerations drive:

- Bio-based rubber alternatives

- Improved recyclability

- Reduced carbon footprint

- Sustainable manufacturing practices

- Circular economy integration

Conclusion

Rubberised cables represent an essential solution for applications requiring flexibility, durability, and environmental resistance. Their unique combination of electrical performance and mechanical properties makes them indispensable for portable equipment, industrial machinery, and harsh environment installations.

The superior flexibility and environmental resistance of rubber sheathed cables provide significant advantages over rigid alternatives in demanding applications. Proper selection, installation, and maintenance ensure optimal performance and service life, delivering reliable electrical power where conventional cables would fail.

As technology advances and environmental considerations become increasingly important, rubberised cables continue to evolve with improved compounds, sustainable manufacturing practices, and enhanced performance characteristics. For applications requiring the ultimate in flexibility and environmental resistance, rubber insulated cables remain the preferred choice for discerning engineers and electrical professionals worldwide.