Quick Answer

Single core wire contains one conductor inside the insulation, making it rigid and ideal for fixed installations like building wiring. Multi core wire bundles multiple insulated conductors together, offering flexibility for movable equipment and complex systems needing multiple circuits.

Single Core vs Multi Core Wire

Key difference: Single core = one thick conductor (rigid, high current). Multi core = multiple thin conductors (flexible, multiple signals).

Understanding Single Core Wire

What Is Single Core Wire?

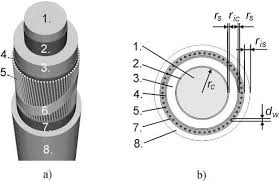

A single-core cable consists of a wire and an external coating layer. The wire is a thick-diameter conductor, protected by the insulator—the external layer.

Structure:

Single Core Wire structure

Characteristics

Construction:

- Single solid or stranded conductor

- Thick wire diameter (carries more current)

- Simple insulation layer

- Available in various gauges (AWG sizes)

Physical properties:

- More rigid than multi core

- Single-core cables normally have larger diameters than multi-core cables

- Better for straight runs

- Less flexible around bends

Electrical properties:

- Higher current capacity than multi-core cable

- High insulation performance and good withstand voltage capability, suitable for transmission of high voltage and large current

- Lower electromagnetic interference (EMI)

- Generally less prone to short circuits and electrical damage

Common Types

By conductor construction:

- Solid conductor: Single piece of metal (most rigid)

- Stranded conductor: Multiple thin strands twisted together (more flexible)

By application:

- Building wire (THHN, THWN)

- Service entrance cable

- Grounding conductors

- Individual phase conductors

Understanding Multi Core Wire

What Is Multi Core Wire?

Multi-core cables consist of multiple conductors bundled within a single cable sheath. The cores can be individually insulated and are capable of carrying multiple signals simultaneously.

Structure:

Multi Core Wire structure

Characteristics

Construction:

- Multiple individually insulated conductors

- Bundled in common outer sheath

- Thinner individual conductors

- Often color-coded for identification

Common configurations:

- 2-core (line + neutral)

- 3-core (line + neutral + ground)

- 4-core (3-phase + neutral)

- 5-core or more (control/signal applications)

Physical properties:

- More flexible than equivalent single core

- Multi-core wires are flexible and suitable for moving or bending lines

- Easier to route in tight spaces

- Multiple circuits in one cable

Electrical properties:

- When the current is large, the required cable is relatively thick. Then it is more suitable to use multi-core cable

- Can transmit multiple signals simultaneously

- Subject to electromagnetic interference between cores

- Twisted designs help cancel interference

Single Core vs Multi Core: Direct Comparison

Comparison Table

| Feature | Single Core | Multi Core |

|---|---|---|

| Conductors | One | Multiple (2-37+) |

| Flexibility | Rigid | Flexible |

| Current capacity | Higher (per cable) | Lower (per core) |

| Installation | Easier pulling | More complex termination |

| Diameter | Larger | Smaller overall |

| Cost | Lower | More costly due to complex manufacturing |

| Applications | Fixed installations | Movable equipment |

| EMI | Relatively small electromagnetic interference | Higher between cores |

| Heat generation | Produce less heat than multi-core cables under same burden | More heat |

| Short circuit risk | Lower | Higher |

| Best for | Power distribution | Control/communication |

Flexibility Comparison

Single Core Wire:

- ✅ Strong and durable

- ✅ More rigid and easier to fix

- ✅ Better for permanent installations

- ❌ Difficult to bend repeatedly

- ❌ Can break with excessive flexing

Multi Core Wire:

- ✅ Highly flexible

- ✅ Withstands repeated bending

- ✅ Ideal for movable equipment

- ❌ More resistant to high stress and temperature

- ❌ Complex joint connections

Installation Comparison

Single Core:

Advantages:

✅ Easier to pull through conduit

✅ Simpler connections (one wire)

✅ Better for long straight runs

✅ Convenient for line splicing

Disadvantages:

❌ Need multiple cables for complete circuit

❌ More time installing separate cables

❌ Takes more conduit space

Multi Core:

Advantages:

✅ Complete circuit in one cable

✅ Fewer cables to manage

✅ Space-efficient

✅ Faster installation (one pull)

Disadvantages:

❌ Heavier and bulkier

❌ All cores must be terminated

❌ Joint handling more complex

❌ Harder to identify individual cores

Electrical Performance

Current Capacity:

For the same total conductor area:

- Single core: 100A (one cable)

- Multi core 3×: ~85A (three cores)

Why? Single-strand copper wire is more expedient in line joints and equipment wiring, and cores in multi-core cables heat each other.

Voltage Drop:

- Single core: Lower drop (less resistance)

- Multi core: Higher drop (thinner conductors, proximity effect)

Skin Effect: With single-core cables, because of the skin effect, the current flows only at their surface, and much of the center is wasted

For high-frequency AC:

- Single core: More affected by skin effect

- Multi core: Less affected (smaller individual conductors)

When to Use Single Core Wire

Best Applications

Building Wiring:

- Preferred for high-current power transmission and environments requiring less flexibility like building wiring and high-voltage substations

- Residential branch circuits

- Commercial power distribution

- Industrial feeders

Fixed Installations:

- Conduit wiring (THHN/THWN)

- Permanent machinery connections

- Service entrance conductors

- Subpanel feeders

High Voltage/Current:

- For conduit wiring or circuits with voltages of 35kv or above, single-core wires are generally recommended

- Transformer connections

- Large motor feeders

- Main distribution panels

Where Rigidity Is Needed:

- Overhead lines

- Bus bars

- Vertical risers

- Straight conduit runs

Advantages in These Applications

✅ Higher current capacity per cable ✅ Lower cost for power distribution ✅ Better heat dissipation ✅ Simpler connections ✅ More durable in fixed locations ✅ Lower EMI for sensitive equipment

Example Scenarios

Residential:

- 120V/240V branch circuits

- THHN wire in conduit

- Individual hot, neutral, ground wires

Commercial:

- 208V/480V 3-phase power

- Large equipment feeders

- Main service conductors

Industrial:

- High-voltage distribution

- Heavy machinery connections

- Motor control centers

When to Use Multi Core Wire

Best Applications

Movable Equipment:

- Power tools and appliances

- Extension cords

- Portable generators

- Mobile machinery

Control Systems:

- Suitable for low-voltage control and communication systems

- PLC wiring

- Instrumentation

- Automation equipment

Limited Space:

- Installation space generally uses multi-core cables as they are flexible, less prone to core breakage, and capable of transmitting multiple signals

- Compact equipment

- Complex routing

- Multiple circuits in tight areas

Frequent Movement:

- Robotics and automation

- Crane and hoist cables

- Stage and theater equipment

- Marine and RV applications

Advantages in These Applications

✅ Flexible for bending and movement ✅ Complete circuits in one cable ✅ Space-efficient installation ✅ Color-coded conductors ✅ Faster to install (one cable) ✅ Organized cable management

Example Scenarios

Household:

- Domestic appliances—TVs, vacuums, refrigerators

- Laptop chargers (line, neutral, ground)

- Extension cords

- Appliance cords

Industrial:

- Heavy machinery—media studios, engineering centers, audios, and cameras

- Control panel wiring

- Instrumentation circuits

- Data transmission

Specialized:

- Communication, data transmission, control systems, railway signal transmission

- Audio/video cables

- Security systems

- Network installations

Selection Criteria

How to Choose Between Single and Multi Core

Consider these factors:

1. Application Type

Choose Single Core for:

- Permanent building installations

- High current requirements

- Simple point-to-point connections

- Fixed equipment

Choose Multi Core for:

- Movable equipment

- Multiple signals/circuits

- Complex control systems

- Flexible installations

2. Current and Voltage

Single Core:

- High current (>50A typically)

- High voltage (>600V)

- Power distribution

- Main feeders

Multi Core:

- Low to medium current

- Low voltage control (<600V)

- Multiple small loads

- Signal transmission

3. Installation Environment

Single Core:

- Straight conduit runs

- Fixed locations

- Industrial settings

- Outdoor overhead

Multi Core:

- Tight spaces

- Frequent bending

- Moving applications

- Indoor equipment

4. Budget Considerations

Cost comparison:

Single Core:

- Lower material cost

- More labor (multiple cables)

- Higher conduit costs (more space)

- Best for: Large power installations

Multi Core:

- Higher material cost

- Less labor (one cable)

- Lower conduit costs

- Best for: Complex control systems

Decision Flowchart

START: What are you wiring?

├─ Fixed building wiring?

│ └─ High current (>20A)?

│ ├─ YES → Single core (THHN in conduit)

│ └─ NO → Could use either (single core cheaper)

│

├─ Movable equipment?

│ └─ Multi core (flexible cable)

│

├─ Multiple circuits in tight space?

│ └─ Multi core (saves space)

│

├─ Control or instrumentation?

│ └─ Multi core (organized wiring)

│

└─ High voltage (>1000V)?

└─ Single core (better insulation)

Common Applications by Type

Single Core Applications

Residential:

- Branch circuit wiring (14, 12, 10 AWG)

- Service entrance conductors

- Grounding electrode conductors

- Individual hot/neutral/ground wires

Commercial:

- Feeder circuits

- Distribution panels

- Equipment connections

- Emergency systems

Industrial:

- Motor feeders

- High-current equipment

- Transformer connections

- Power distribution

Utility:

- Overhead lines

- Underground distribution

- Substation wiring

- Transmission lines

Multi Core Applications

Household:

- Appliance cords

- Extension cords

- Lamp cords

- Device chargers

Industrial Control:

- Motor control cables

- PLC wiring

- Instrumentation

- Process control

Communication:

- Telephone cables

- Data transmission

- Network cables

- Audio/video

Specialty:

- Marine and RV

- Stage lighting

- Robotics

- Automotive

Installation Best Practices

Single Core Installation

General guidelines:

1. Use proper conduit fill:

- Maximum 40% fill for 3+ conductors

- 31% for 2 conductors

- 53% for 1 conductor

2. Color coding:

- Hot: Black, red, blue

- Neutral: White or gray

- Ground: Green or bare

3. Support requirements:

- Secure every 4.5 feet

- Within 12 inches of boxes

- Prevent excessive pulling

4. Bending radius:

- Minimum 8× cable diameter for permanent

- 10× for temporary installations

Multi Core Installation

General guidelines:

1. Handle with care:

- Don't exceed bend radius

- Avoid twisting during pull

- Support weight properly

2. Strain relief:

- Essential at connections

- Prevents wire pull-out

- Use appropriate fittings

3. Core identification:

- Follow color code

- Label if needed

- Test before termination

4. Termination:

- Strip carefully (don't nick cores)

- Use proper connectors

- Crimp or solder as required

- Apply heat shrink if needed

Common Installation Mistakes

❌ Mistake 1: Wrong wire type

- Using multi core for high current

- Using single core for frequent flexing

❌ Mistake 2: Exceeding bend radius

- Damages insulation

- Breaks conductors

- Reduces lifespan

❌ Mistake 3: Poor connections

- Loose terminals

- Inadequate crimping

- Mixed metals (corrosion)

❌ Mistake 4: Overloading

- Exceeding ampacity

- Insufficient conductor size

- Improper bundling (derating)

Maintenance and Safety

Single Core Maintenance

Regular inspection:

- Check for insulation damage

- Look for overheating signs

- Verify connections tight

- Test ground continuity

Safety concerns:

- Exposed conductors dangerous

- Higher voltage capability

- Individual wires can separate

- Label clearly

Multi Core Maintenance

Regular inspection:

- Check outer sheath for damage

- Inspect at bend points

- Look for core separation

- Verify strain relief

Safety concerns:

- Damaged cores may short together

- Overheating less visible (inside)

- Replace entire cable if damaged

- Don't repair with tape

Lifespan

Expected service life:

Single Core:

- Building wire: 30-50 years

- Industrial: 20-30 years

- Factors: temperature, moisture, mechanical stress

Multi Core:

- Fixed installation: 20-30 years

- Movable equipment: 5-15 years

- Portable cords: 2-10 years

- Depends heavily on flexing cycles

Special Considerations

Skin Effect and AC Current

The phenomenon: With single-core cables, because of the skin effect, the current flows only at their surface, and much of the center is wasted

Impact:

- Significant at high frequencies (>1kHz)

- Reduces effective conductor area

- Increases resistance and heat

- Multi core cables less affected

Solutions:

- Use stranded conductors

- Consider multi core for AC

- Use multiple parallel cables

- Calculate skin depth

Electromagnetic Interference (EMI)

Single Core:

- One further thing to be concerned about when it comes to single-core cables is the possibility that they may produce powerful magnetic fields

- Can affect nearby equipment

- Keep away from sensitive circuits

Multi Core:

- Cores interfere with each other

- Twisted pairs reduce EMI

- Shielded cables available

- Better for low-level signals

Temperature Considerations

Heat generation:

Single Core:

- Under the same burden, single-core cables produce less heat than multi-core cables, rendering them safer to use

- Better heat dissipation

- Higher ampacity ratings

Multi Core:

- Cores heat each other

- Outer sheath traps heat

- Requires derating

- Check manufacturer specs

Frequently Asked Questions

Can I use multi core wire for house wiring?

While possible, it's not standard practice in most regions. Building codes typically require individual THHN/THWN conductors in conduit for permanent installations. Multi core cable (like Romex) is allowed in some applications but check local codes.

Is single core wire more expensive than multi core?

For power applications, single core is usually cheaper per ampere of capacity. However, you need multiple single core cables for a complete circuit. Multi core is more expensive per foot but may save on installation labor and materials.

Which is better for outdoor use?

It depends:

- Single core: Better for overhead lines, buried conduit, permanent installations

- Multi core: Better for temporary connections, portable equipment, if properly rated for outdoor use (UF cable, SOOW cord, etc.)

Both need appropriate insulation ratings for the environment.

Can I replace single core with multi core?

Only if the multi core meets the same electrical requirements (ampacity, voltage rating, temperature rating) and code permits it for that application. Often not allowed for building wiring. Check local electrical codes.

Why do appliances use multi core cords?

Domestic appliances use multi-core cables since they are easy to maneuver, and appliances need flexibility for movement. A complete circuit (hot, neutral, ground) in one flexible cable is safer and more convenient than separate wires.

Do I need different tools for single vs multi core?

Basic tools are similar (strippers, crimpers, etc.), but:

- Single core: Easier to strip and terminate

- Multi core: May need special strippers to avoid damaging multiple cores, larger crimping tools for the whole cable

Which type lasts longer?

In fixed installations, both last similarly (20-50 years). For movable applications, single core breaks faster from flexing. Multi core designed for flexibility lasts much longer in these applications.

Is stranded single core the same as multi core?

No. Stranded single core has multiple thin strands making up ONE conductor, all working together. Multi core has multiple separate CONDUCTORS, each insulated, carrying different currents or signals.

Conclusion

The choice between single core and multi core wire depends entirely on your specific application, installation environment, and electrical requirements.

Choose Single Core Wire when:

- ✅ Installing permanent building wiring

- ✅ Handling high voltage or current

- ✅ Running straight conduit with minimal bends

- ✅ Cost is a primary concern for power distribution

- ✅ Maximum current capacity is needed

Choose Multi Core Wire when:

- ✅ Wiring movable equipment or appliances

- ✅ Installing in tight spaces with multiple circuits

- ✅ Flexibility is essential

- ✅ Multiple signals need transmission

- ✅ Faster installation is priority

Key Takeaways:

- Single core offers higher current capacity and durability for fixed installations

- Multi core provides flexibility and convenience for movable equipment

- Building codes often dictate which type must be used

- Neither is universally 'better'—each excels in its intended application

- Proper installation and maintenance ensure long service life for both types