The Hidden Technology Inside the Jacket

When we talk about fire safety in electrical systems, we often focus on the standards and the results. But what actually happens inside a cable when the temperature hits 950°C? The answer lies in the flame retardant material and specialized polymers used in its construction.

flame-retardant-material

Understanding what is fire retardant material and how it interacts with heat is essential for engineers who need to specify cables for high-risk environments.

I. How Flame Retardant Materials Work

To stop a fire, you must break the 'Fire Triangle' (Heat, Fuel, and Oxygen). Flame resistant materials in cables are engineered to disrupt one or more of these elements through three primary mechanisms:

1. Endothermic Cooling (Heat Removal)

Some materials, like Aluminum Trihydrate (ATH), release water vapor when heated. This chemical reaction absorbs a massive amount of heat energy, cooling the cable surface and delaying ignition.

2. Char Formation (Fuel Shielding)

Certain fire retardant materials are 'intumescent.' When exposed to heat, they swell up to several times their original size, creating a thick layer of carbonized 'char.' This char acts as an insulator, protecting the inner conductors from the flame.

3. Vapor Phase Suppression (Oxygen Displacement)

Some materials release non-combustible gases that dilute the oxygen surrounding the cable, effectively 'starving' the fire of the air it needs to continue burning.

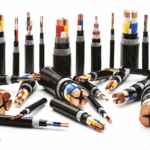

II. Key Materials in Fire-Rated Cable Design

Different layers of a cable require different flame resistant materials to achieve specific safety ratings.

1. Mica Tape: The Heart of Fire Resistance

If a cable is rated for 'Circuit Integrity' (maintaining power during a fire), it almost certainly uses Mica Tape. Mica is a mineral that can withstand temperatures up to 1000°C without melting. It is wrapped around the copper conductor to ensure that even if the plastic insulation burns away, the electricity doesn't short-circuit.

2. LSZH (Low Smoke Zero Halogen) Polymers

In the past, many cables used PVC, which releases toxic chlorine gas when burned. Modern fire safe cables use LSZH flame retardant materials. These are typically polyolefin-based compounds filled with minerals that produce almost no smoke and zero acid gases.

3. Silicone Rubber

Specialized silicone compounds are often used as insulation. When burned, they turn into a non-conductive 'ash' (silica) that continues to provide electrical insulation for the copper core.

III. Material Comparison Table

IV. Why Material Quality Matters for Fire Rated Wires

Not all flame-resistant materials are created equal. Poorly formulated materials might pass a basic flame test but fail under real-world conditions involving mechanical shock or water spray (as required by BS 6387 CWZ).

When selecting a supplier, always look for cables that use high-purity mica and stabilized LSZH compounds to ensure consistent performance over the 20 to 30-year lifespan of the installation.

Conclusion: Engineering for the Unthinkable

The science of fire resistant materials is constantly evolving. From the cooling effects of hydrated minerals to the heat-shielding power of mica, every layer of a fire rated cable is a masterpiece of material science designed to buy precious time during an emergency.

Whether you are designing a high-rise office or a deep-sea tunnel, understanding what is fire retardant material helps you make informed choices that protect both assets and lives.