If you've ever watched an industrial robot arm at work, you'll see a complex dance of power, data, and control cables flexing with every movement. These aren't just any wires; they're specialized robot cables, engineered to withstand the extreme, high-frequency motion that would quickly destroy a standard cable.

This guide will explain what makes robot cables so unique, why proper robot cable management is critical, and how to choose the right cables for your robotic applications.

What Are Robot Cables?

Robot cables are a type of flexible cable designed for repeated, high-speed movement. They are the nervous system of any automated system, transmitting power and signals to and from the robotic arm or machine head.

What sets them apart from standard cables?

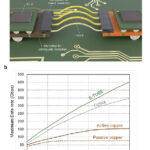

- Conductor Structure: Unlike rigid solid wires, robot cables use a high-strand, fine-wire copper conductor. This finely-stranded design allows the cable to bend and flex thousands, even millions, of times without breaking.

- Insulation and Jacket Materials: The outer jacket and inner insulation are made from highly durable materials like PUR (polyurethane) or TPE (thermoplastic elastomer). These materials resist abrasion, oil, chemicals, and extreme temperatures, all of which are common in an industrial environment.

- Anti-Torsion Design: Many robot cables are built with a special internal structure to handle torsional stress (twisting motions). This prevents the internal wires from coiling up and failing over time.

The Challenge of Robot Cable Management

Without proper management, cables on a moving robot arm can become tangled, worn out, and fail prematurely. This leads to costly downtime, maintenance, and lost productivity.

The solution lies in two primary methods of robot cable management:

- Cable Carriers (Energy Chains): These are flexible, protective tracks that guide the cables along a set path. They prevent tangling, control the bend radius, and shield the cables from external damage. Cable carriers are ideal for linear movements and multi-axis applications where cables need a defined route.

- Robot Dress Packages: A more integrated solution, a dress package bundles all power, data, and pneumatic lines together and secures them to the robot's arm. This ensures that the cables move in a controlled, synchronous way with the robot's movements, preventing stress and wear.

How to Choose the Right Robot Cable

Selecting the right cable for your application is crucial for long-term reliability. Consider these key factors:

- Motion Type: Do you need a cable for continuous flexing, torsional twisting, or a combination of both? Different cables are optimized for different types of movement.

- Environmental Factors: What will the cable be exposed to? Make sure the jacket material is resistant to common industrial hazards like oil, coolants, or high temperatures.

- Key Performance Metrics:

- Bend Radius: The minimum radius the cable can bend without damage. A smaller number means more flexibility.

- Flexing Life: The number of bending cycles the cable can withstand before failure. This metric is a key indicator of its durability.

The Final Word on Robot Cables

A high-quality robot cable and a well-designed management system are non-negotiable for the long-term reliability of any automated system. They are the unsung heroes that keep production running smoothly.

Ready to find the right cables for your next project? Explore our full range of durable and high-performance robot cables designed for the toughest industrial applications.