The ubiquitous electrical cable is often taken for granted, but its reliability hinges on a critical, often-unseen component: insulation. This protective layer is the unsung hero, ensuring power flows safely and efficiently while preventing short circuits, electrical fires, and protecting the cable itself from environmental and mechanical damage. Choosing the right type of cable insulation is paramount in any electrical application, from simple household wiring to complex industrial power grids.

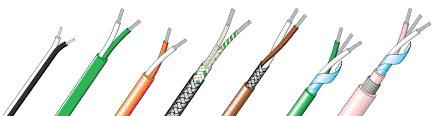

types of insulation in cables

Why Insulation Matters: The Core Function

At its heart, cable insulation serves as a dielectric material, meaning it's a poor conductor of electricity. Its primary functions are:

Electrical Isolation: Preventing the current-carrying conductor from making unintended contact with other conductors, grounded surfaces, or surrounding objects.

Protection: Shielding the conductor from environmental factors (moisture, chemicals, extreme temperatures) and mechanical stresses (abrasion, crushing).

Safety: Minimizing the risk of electric shock and fire hazards.

The effectiveness of an insulation material is primarily measured by its dielectric strength (the maximum electric field it can withstand without breaking down) and its insulation resistance (how well it opposes the flow of leakage current).

⚡ Key Types of Cable Insulation Materials

Cable insulation materials are engineered for specific operating environments and voltage levels. They are broadly categorized into thermoplastic, thermosetting, and mineral-based compounds.

1. Thermoplastic Insulations

Thermoplastic materials become soft when heated and hard when cooled, allowing them to be easily processed. They are widely used due to their cost-effectiveness and flexibility.

Polyvinyl Chloride (PVC):

Pros: Highly popular due to its excellent flame resistance, durability, moisture resistance, and low cost.

Cons: Not suitable for very high temperatures, as it can soften, or extremely low temperatures, where it can become brittle. It can also emit toxic fumes when burning.

Use Cases: General-purpose wiring, low-voltage power and control cables (e.g., THHN/THWN).

Polyethylene (PE) / High-Density Polyethylene (HDPE):

Pros: Excellent dielectric properties, superb moisture resistance, and very low dielectric constant, making it ideal for high-frequency applications.

Cons: Flammable unless treated with additives.

Use Cases: Communication cables, coaxial cables, and some medium-voltage power cables (especially those buried underground).

2. Thermosetting Insulations

Thermosetting materials undergo a chemical change during the manufacturing process (vulcanization or cross-linking) that makes their shape permanent. They do not soften when reheated, giving them superior thermal stability.

Cross-Linked Polyethylene (XLPE or PEX):

Pros: Significantly improved thermal resistance and mechanical strength compared to standard PE. It can withstand higher conductor temperatures (up to 90°C continuous, 250°C short-circuit). Highly resistant to aging and chemicals.

Cons: Higher cost than PVC.

Use Cases: High-voltage transmission and distribution cables, critical industrial wiring, and applications requiring high reliability.

Ethylene Propylene Rubber (EPR):

Pros: Excellent flexibility, superior resistance to ozone and corona (a type of electrical discharge), and good thermal properties. It is often preferred for flexible cables and mining applications.

Cons: Can have higher moisture absorption than XLPE.

Use Cases: Flexible industrial cables, high-temperature leads, and marine wiring.

Silicone Rubber:

Pros: Outstanding heat resistance, maintaining its properties even at very high temperatures (often up to 180°C). Excellent flexibility.

Cons: Low mechanical strength and poor abrasion resistance.

Use Cases: Heating appliances, oven wiring, and other extreme high-temperature environments.

3. Specialty and Inorganic Insulations

These materials are used when standard insulations fail to meet the requirements of extreme environments.

Mineral Insulated (MI) Cable:

Composition: Copper conductors encased in a copper sheath and separated by tightly packed Magnesium Oxide (MgO) powder.

Pros: Virtually fireproof (melting point of sheath is around 1083°C), excellent for high-temperature and fire-survival applications, completely waterproof and highly robust.

Use Cases: Fire-rated circuits, intrinsically safe systems, and process heating.

Fluorinated Polymers (e.g., PTFE, FEP, PFA):

Pros: Exceptional chemical inertness, excellent temperature stability (both high and low), very low friction, and superb dielectric properties.

Cons: High cost.

Use Cases: Aerospace, medical equipment, and chemical plants where resistance to aggressive substances is mandatory.

🌡️ The Importance of Temperature Ratings

A critical factor in selecting insulation is its temperature rating. This defines the maximum continuous operating temperature of the conductor for which the insulation is designed. The National Electrical Code (NEC) in the US and international standards (like IEC) classify insulation types with designations that reflect this rating (e.g., Thermoplastic Heat-resistant Water-resistant, 75°C or 90°C).

| Insulation Type (Common Abbreviation) | Max Continuous Operating Temperature | Key Feature |

| PVC (e.g., THHN/THWN) | 75°C to 90°C | Flame Retardant, Low Cost |

| XLPE (XHHW-2) | 90°C | Excellent Heat and Chemical Resistance |

| EPR (RHW) | 90°C | Flexibility, Ozone Resistance |

| Silicone Rubber | Up to 180°C | Extreme High-Temperature Stability |

✍️ Expert Tip: The Power of System Design

When selecting cable insulation, an electrical engineer doesn't just look at the required voltage and current. They consider the entire system environment:

Ambient Temperature: Will the cable be near heat sources?

Chemical Exposure: Will it be exposed to oils, solvents, or corrosive vapors?

Mechanical Stress: Will it be subject to frequent bending, pulling, or crushing?

Installation Method: Will it be run in conduit, tray, or direct burial?

For instance, an outdoor tray cable might require XLPE for its UV and moisture resistance, while a control circuit running through a furnace room might necessitate a Silicone Rubber or MI cable for fire and heat survival. Always consult with relevant electrical codes and professional engineers to ensure the chosen insulation provides a safe and durable solution for your specific application.