When choosing electrical wire or cable, one of the most common questions is whether tinned copper or bare copper offers better conductivity. Both materials use the same base metal—copper—but the surface treatment (or lack of it) affects performance in specific environments. Below is a detailed comparison to help you understand how conductivity differs and when each type is the better choice.

tinned copper vs bare copper conductivity

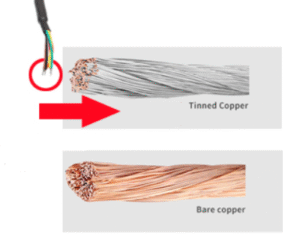

What Is Bare Copper?

Bare copper is uncoated, pure copper conductor.

It is the standard conductor material in most electrical applications.

Known for excellent electrical conductivity.

Typically used in indoor and dry environments where corrosion is not a major concern.

What Is Tinned Copper?

Tinned copper is standard copper coated with a thin layer of tin.

The purpose of tinning is corrosion resistance, especially in wet, salty, or high-moisture environments.

Common in marine, automotive, and solar applications.

Important: Tinning does not significantly change the base copper’s electrical properties—but the coating does have a minor impact.

Conductivity Comparison: Tinned vs. Bare Copper

1. Pure Electrical Conductivity

Bare copper has slightly higher conductivity.

Tinned copper has slightly lower conductivity because tin is less conductive than copper.

Copper conductivity: ~100% IACS

Tin conductivity: ~15% IACS

However, the tin coating is extremely thin, so the reduction in overall conductivity is minimal—usually less than 1–2%.

Bottom line:

➡ Bare copper conducts electricity slightly better.

➡ The difference is small and not noticeable in most practical applications.

2. Corrosion & Long-Term Conductivity

Here’s where tinned copper wins:

Bare Copper

Oxidizes when exposed to air and moisture.

Oxide layer increases electrical resistance over time.

In humid, marine, or outdoor environments, performance can degrade.

Tinned Copper

Tin prevents oxidation and corrosion.

Maintains low resistance longer.

Offers superior long-term conductivity in harsh environments.

Long-Term Conclusion:

➡ In corrosive or wet environments, tinned copper maintains better conductivity over time than bare copper.

3. Flexibility and Handling

| Property | Bare Copper | Tinned Copper |

|---|---|---|

| Conductivity | Slightly higher | Slightly lower initially |

| Corrosion Resistance | Low | Very high |

| Long-term Conductivity Stability | Moderate | Excellent |

| Cost | Lower | Higher |

| Best Use | Indoor, dry | Outdoor, marine, automotive, solar |

Which Should You Choose?

Choose Bare Copper when:

You need the absolute highest conductivity

Installation is indoors or in dry conditions

Cost is a major concern

You are running ground wires, THHN, or general building wire

Choose Tinned Copper when:

You are in marine, coastal, or high-moisture environments

You need the wire to last decades without corrosion

It’s used in DC circuits, solar wiring, battery banks, automotive systems

Reliability in harsh conditions matters more than small cost differences