When it comes to heavy-duty power cable solutions, Type W cable stands out as one of the most versatile and reliable options available on the market today. This comprehensive guide will explore everything you need to know about Type W cables, from their construction specifications to applications and advantages over other cable types.

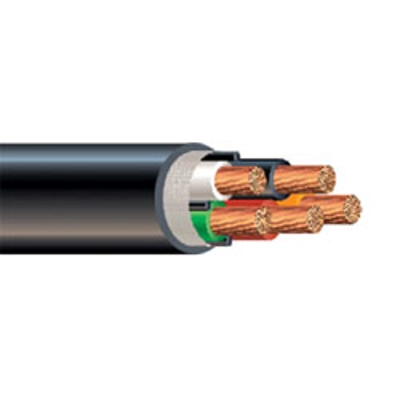

4/0 5C Type W Portable Power Cable

What Is Type W Cable?

Type W cable is a heavy-duty, flexible power cable designed for use in demanding industrial environments. Characterized by its robust construction and excellent resistance properties, Type W cable is specifically engineered to withstand harsh conditions while delivering consistent electrical performance. These portable power cables are commonly used for temporary power distribution in construction sites, mining operations, and other industrial applications.

Key Specifications and Construction Features

Type W cable consists of several carefully engineered components that contribute to its durability and performance:

- Conductors: Made from flexible stranded copper for maximum conductivity and flexibility

- Insulation: Features EPR (Ethylene Propylene Rubber) insulation rated for 600V to 2000V applications

- Temperature Rating: Typically designed to operate in environments ranging from -40°C to +90°C

- Jacket Material: Heavy-duty EPDM or neoprene outer jacket providing excellent resistance to:

- Oils and chemicals

- Abrasion and cuts

- UV radiation

- Moisture and water

- Flexibility: Remains flexible even in extreme cold conditions

- Available Configurations: 2-conductor to 5-conductor options with various AWG sizes

Common Applications for Type W Cable

The versatility of Type W cable makes it suitable for numerous industrial applications, including:

Construction Industry

Type W cables are frequently used on construction sites to power temporary lighting, heavy machinery, and portable tools. Their durability and resistance to environmental factors make them ideal for outdoor use in varying weather conditions.

Mining Operations

Underground mining requires cables that can withstand harsh conditions, including moisture, abrasion, and chemical exposure. Type W cables deliver reliable power to mining equipment, ventilation systems, and lighting in these challenging environments.

Manufacturing Facilities

In manufacturing settings, Type W cables connect motors, control systems, and machinery that require flexible power solutions with the ability to withstand oils, chemicals, and mechanical stress.

Portable Power Distribution

Whether for outdoor events, emergency services, or temporary installations, Type W cables are the go-to choice for portable power distribution systems that need to be set up and dismantled regularly.

Oil and Gas Industry

The oil and gas sector relies on Type W cables for their resistance to chemicals and ability to perform in extreme temperatures, making them suitable for drilling operations and processing facilities.

Type W Cable vs. Other Cable Types

When comparing Type W cable to other industrial cable types like SO cable, SOOW cable, or Type G cable, several factors distinguish Type W as the preferred choice for certain applications:

| Feature | Type W Cable | Standard SO Cable | Type G Cable |

|---|---|---|---|

| Voltage Rating | 600-2000V | 600V | 2000V |

| Temperature Range | -40°C to +90°C | -25°C to +75°C | -40°C to +90°C |

| Oil Resistance | Excellent | Good | Excellent |

| Abrasion Resistance | Superior | Moderate | Superior |

| Flexibility | Highly flexible | Flexible | Less flexible |

| Water Resistance | Excellent | Good | Excellent |

| Common Applications | Heavy industrial | Light industrial | Extra heavy industrial |

Benefits of Using Type W Cable

Choosing Type W cable for your industrial applications offers numerous advantages:

- Extended Durability: The robust construction ensures a longer operational lifespan even in demanding conditions.

- Excellent Flexibility: Maintains flexibility in extreme temperatures, making installation easier in challenging environments.

- Superior Resistance Properties: Resistant to oils, chemicals, abrasion, and environmental factors that would damage standard cables.

- Versatile Application Range: Suitable for both indoor and outdoor installations across multiple industries.

- Cost-Effective Long-Term Solution: While the initial investment may be higher than standard cables, the extended lifespan and reliability make Type W cables more economical over time.

- Safety Compliance: Meets or exceeds industry safety standards for industrial power applications.

Installation Best Practices

To maximize the performance and lifespan of Type W cables, follow these installation guidelines:

- Avoid exceeding the minimum bend radius specified by the manufacturer

- Use appropriate cable management systems to prevent unnecessary strain

- Install protective measures at points where cables may experience mechanical stress

- Regularly inspect cables for signs of wear or damage, particularly in harsh environments

- Ensure proper termination and connection methods are used to prevent electrical faults

Selecting the Right Type W Cable for Your Application

When choosing Type W cable, consider the following factors:

- Voltage Requirements: Ensure the cable's voltage rating meets or exceeds your application needs

- Conductor Size: Select the appropriate AWG size based on current requirements and distance

- Number of Conductors: Determine how many conductors (typically 2-5) are needed for your application

- Environmental Conditions: Consider the specific environmental challenges the cable will face

- Certification Requirements: Verify that the cable meets relevant industry standards and certifications

- Cable Length: Calculate the required length with additional allowance for routing and movement

Environmental and Safety Considerations

Type W cables are designed with both performance and safety in mind. Many modern Type W cables are manufactured to be:

- RoHS compliant (Restriction of Hazardous Substances)

- Free from halogens and low-smoke producing materials

- Resistant to oils and chemicals that could degrade standard cables

- Compliant with relevant UL, CSA, and MSHA approvals

Common Type W Cable Variations

Several variations of Type W cable are available for specialized applications:

- Type W: Standard version for general industrial use

- Type G-GC: Includes ground check conductor for monitoring ground continuity

- Type G: Similar to Type W but with additional features for specific applications

- Type SHD-GC: Mining-specific variation with enhanced shielding

- Type W-PP: Features a parallel path ground conductor

Conclusion: Why Type W Cable Continues to Be an Industry Standard

Type W cable remains the preferred choice for demanding industrial applications due to its unmatched combination of durability, flexibility, and resistance properties. While newer cable types continue to emerge, the proven performance of Type W cable ensures its continued relevance in construction, mining, manufacturing, and other heavy industrial sectors.

Whether you're powering temporary equipment at a construction site, supplying electricity to mining operations, or establishing flexible connections in a manufacturing facility, Type W cable delivers the reliability and performance necessary for mission-critical applications.

By understanding the specifications, applications, and benefits of Type W cable, you can make informed decisions about your industrial power needs and ensure that your operations run safely and efficiently, even in the most challenging environments.

1 comment

Magic 8 ball 09/09/2025

It's amazing in favor of me to have a site, which is good for my experience. thanks admin