When winter hits or temperatures drop in industrial environments, frozen pipes and inconsistent temperatures can cause costly damage or process interruptions. One of the most reliable and energy-efficient solutions to this problem is the self-regulating heat trace cable—a technology that automatically adjusts its heat output based on surrounding temperatures.

self regulating heat trace cable

In this article, we’ll explore what self-regulating heating cables are, how they work, where they're used, and why they’re an essential choice for both residential and industrial applications.

What Is a Self-Regulating Heat Trace Cable?

A self-regulating heat trace cable (also called a self-limiting heat cable) is a type of electric heating cable designed to maintain or protect temperatures in pipes, tanks, roofs, and other critical systems. The key feature that sets it apart from traditional heating systems is its ability to automatically change its heat output depending on the surface or ambient temperature.

This means the cable produces more heat when temperatures drop and less heat when temperatures rise—without the need for a separate thermostat in many cases. This dynamic adjustment not only saves energy but also prevents overheating and cable damage.

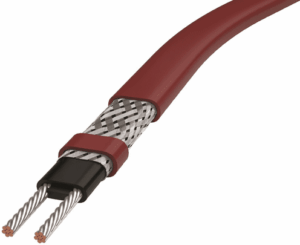

self regulating heat trace cable work

How Does It Work?

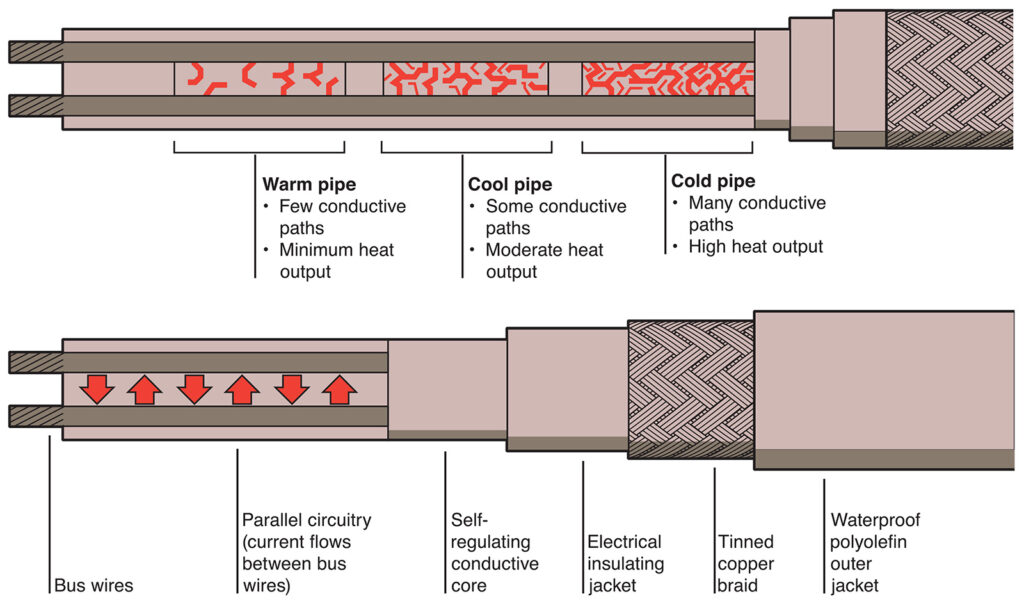

The heart of a self-regulating heat cable lies in its conductive polymer core that sits between two parallel bus wires. This core contains carbon particles that respond to temperature:

When it’s cold: The polymer contracts, allowing more electrical paths to form. This increases electrical current flow and heat output.

When it’s warm: The polymer expands, reducing the number of conductive paths. As a result, heat output automatically decreases.

This self-regulation ensures the system is always working as efficiently and safely as possible.

Common Applications

Self-regulating heat cables are used in a wide range of applications, including:

Pipe freeze protection: Preventing water or chemical pipes from freezing in cold weather.

Roof and gutter de-icing: Melting snow and ice to avoid damage from ice dams.

Industrial temperature maintenance: Keeping process pipelines or tanks at a stable temperature.

Fire sprinkler systems: Ensuring reliable water flow in cold climates.

Oil and gas facilities: Tracing critical lines in hazardous environments.

Because these cables can be cut to length and overlapped safely, they are also ideal for complex pipe networks or irregular installations.

Key Advantages of Self-Regulating Heat Cables

Compared to constant wattage or mineral-insulated heating cables, self-regulating cables offer several important benefits:

✅ Energy efficiency: Uses only as much power as needed, reducing energy bills.

✅ Safety: Won’t overheat, even if cables touch or cross.

✅ Ease of installation: No custom length ordering—cut and connect on-site.

✅ Durability: Resistant to moisture, UV, and mechanical wear with the right outer jacket.

✅ Flexible applications: Suitable for residential, commercial, and hazardous areas.

In industrial setups, self-regulating heating cables can be paired with thermostats, controllers, and explosion-proof accessories for more advanced needs.

Choosing the Right Cable

Not all self-regulating heat trace cables are the same. When selecting a cable, consider:

Power rating (watts per meter or foot): Higher wattage for larger pipes or harsher conditions.

Voltage: Common options include 120V, 220V, 240V, and 277V.

Outer jacket material: TPE, XLPE, or FEP, depending on exposure to chemicals or weather.

Certifications: UL, CSA, CE, and ATEX/IECEx for hazardous locations.

Correct matching of cable type to environment ensures long-term reliability and compliance with safety regulations.

Final Thoughts

Self-regulating heat trace cables have become the go-to solution for freeze protection, temperature maintenance, and de-icing applications across multiple industries. Their built-in intelligence to adapt to temperature changes makes them safer and more efficient than traditional heating systems.

Whether you're a facility manager preparing for winter or an engineer specifying a critical pipeline solution, understanding the value of self-regulating heat cables can help you prevent damage, save energy, and maintain operations smoothly.

If you're planning a heat trace system and need guidance on cable selection, wattage calculation, or installation support, consult with a cable supplier or systems integrator experienced in electric heat tracing solutions.