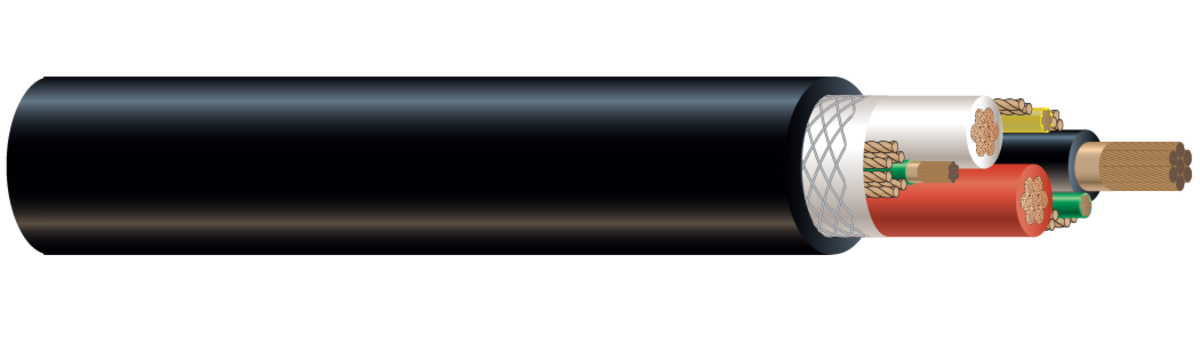

When dealing with outdoor electrical installations, marine applications, or wet environments, regular electrical wire simply won't suffice. Waterproof wire provides the protection and reliability needed for these challenging conditions. Understanding the different types, applications, and installation methods will help you choose the right waterproof wire for your specific project.

water proof wire

What Is Waterproof Wire?

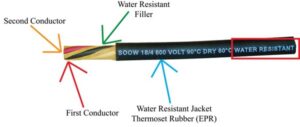

Waterproof wire, also known as water-resistant or marine-grade wire, is specially designed electrical cable that can withstand exposure to moisture, water, and harsh environmental conditions. Unlike standard electrical wire, waterproof wire features enhanced insulation, specialized jacketing, and sometimes sealed construction to prevent water ingress.

Key Characteristics:

- Water-resistant outer jacket

- Enhanced insulation materials

- Corrosion-resistant conductors

- UV-resistant properties

- Temperature tolerance

- Chemical resistance

Types of Waterproof Wire

1. Marine Wire

Primary Features:

- Tinned copper conductors prevent corrosion

- XLPE or silicone insulation

- Flame-retardant properties

- Salt water resistance

- Temperature range: -40°F to 221°F

Common Applications:

- Boat electrical systems

- Marine lighting

- Navigation equipment

- Bilge pumps

- Shore power connections

2. Burial-Rated Cable

Design Specifications:

- Heavy-duty polyethylene jacket

- Direct burial capability

- Moisture barrier protection

- Rodent-resistant construction

- Long-term underground stability

Typical Uses:

- Underground electrical runs

- Landscape lighting systems

- Outdoor power distribution

- Irrigation control systems

- Security camera installations

3. Submersible Wire

Special Properties:

- Completely waterproof construction

- Pressure-resistant design

- Flexible even when wet

- Low-voltage applications

- Sealed connector compatibility

Applications:

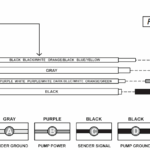

- Submersible pumps

- Pond and fountain equipment

- Underwater lighting

- Well pump connections

- Aquarium systems

4. Outdoor Extension Cords

Weather-Resistant Features:

- Heavy-duty rubber or vinyl jacket

- Reinforced plug connections

- UV stabilized materials

- Cold weather flexibility

- SJTW or SJEOW ratings

Common Uses:

- Outdoor power tools

- Holiday lighting

- Temporary power needs

- Construction sites

- Event installations

Wire Ratings and Standards

IP (Ingress Protection) Ratings

Understanding IP ratings helps select appropriate waterproof wire:

IP65: Dust-tight and protected against water jets IP66: Dust-tight and protected against powerful water jets IP67: Dust-tight and protected against temporary immersion IP68: Dust-tight and protected against continuous submersion

NEMA Ratings

NEMA 4X: Weather-resistant and corrosion-resistant NEMA 6P: Submersible and pressure-resistant NEMA 7: Explosion-proof for hazardous locations

UL and AWG Standards

UL Listed: Safety certification for electrical products AWG Ratings: Wire gauge specifications for current capacity Temperature Ratings: Operating temperature ranges Voltage Ratings: Maximum voltage handling capacity

Applications and Use Cases

Residential Applications

Outdoor Lighting Systems:

- Landscape lighting installations

- Security flood lights

- Pathway and garden lighting

- Holiday decoration connections

- Pool and spa lighting

Home Automation:

- Outdoor security cameras

- Irrigation system controls

- Gate and garage door operators

- Outdoor speakers and entertainment

- Smart home sensors

Commercial Applications

Building Exteriors:

- Sign lighting and displays

- Parking lot lighting

- Building security systems

- HVAC outdoor units

- Emergency lighting systems

Industrial Uses:

- Manufacturing equipment

- Warehouse applications

- Agricultural systems

- Mining operations

- Chemical processing facilities

Marine and Aquatic Applications

Boat Electrical Systems:

- Engine compartment wiring

- Navigation light circuits

- Bilge pump connections

- Radio and GPS installations

- Charging system wiring

Dock and Marina:

- Shore power pedestals

- Dock lighting systems

- Boat lift controls

- Security systems

- Utility connections

Agricultural Applications

Farm Operations:

- Irrigation control systems

- Barn and shed wiring

- Equipment power supplies

- Livestock water systems

- Grain handling equipment

Selecting the Right Waterproof Wire

Environmental Considerations

Temperature Extremes:

- Arctic conditions: Silicone insulated wire

- High heat: THHN or XLPE insulation

- Variable temperatures: Multi-rated cables

- Thermal cycling: Flexible constructions

Chemical Exposure:

- Oil resistance: Neoprene jacketed wire

- Acid environments: Teflon insulated cables

- Salt water: Tinned copper conductors

- Cleaning chemicals: Chemical-resistant jackets

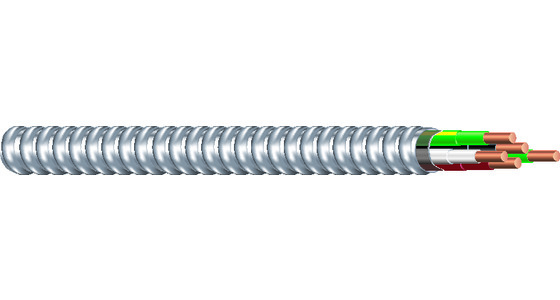

Physical Stress:

- Frequent flexing: Extra-flexible constructions

- Mechanical protection: Armored cables

- Rodent damage: Steel-tape armor

- Abrasion resistance: Tough outer jackets

Electrical Requirements

Current Capacity:

- Calculate load requirements

- Consider voltage drop over distance

- Account for ambient temperature

- Include safety margins

Voltage Requirements:

- Low voltage: 12V-24V systems

- Line voltage: 120V-240V applications

- High voltage: Industrial applications

- DC vs AC considerations

Installation Best Practices

Proper Planning

Route Selection:

- Avoid sharp bends and corners

- Plan for thermal expansion

- Consider accessibility for maintenance

- Minimize exposure to damage

Connection Points:

- Use waterproof connectors

- Apply dielectric grease

- Ensure proper sealing

- Plan for disconnection needs

Installation Techniques

Underground Installation:

- Proper burial depth (typically 18-24 inches)

- Use warning tape above cables

- Backfill with suitable materials

- Mark cable locations

Above-Ground Installation:

- Secure cables properly

- Provide drip loops

- Use appropriate supports

- Protect from physical damage

Connection Methods

Waterproof Connectors:

- Heat-shrink connectors with sealant

- Twist-on wire nuts with silicone

- Compression connectors

- Sealed junction boxes

Sealing Techniques:

- Electrical tape with self-amalgamating tape

- Heat-shrink tubing with adhesive

- Liquid electrical tape

- Silicone sealants

Common Mistakes to Avoid

Installation Errors

Inadequate Protection:

- Using indoor-rated wire outdoors

- Insufficient burial depth

- Poor connection sealing

- Ignoring UV exposure

Improper Sizing:

- Undersized conductors

- Inadequate ampacity calculations

- Ignoring voltage drop

- Wrong insulation rating

Maintenance Oversights

Regular Inspection:

- Check for jacket damage

- Verify connection integrity

- Monitor for corrosion

- Test insulation resistance

Cost Considerations

Initial Investment

Wire Costs:

- Marine wire: $1-5 per foot

- Burial cable: $0.50-3 per foot

- Submersible wire: $2-8 per foot

- Specialty cables: $5-20 per foot

Installation Costs:

- Professional installation: $3-10 per foot

- Trenching and burial: $2-5 per foot

- Connector and junction costs

- Testing and certification

Long-Term Value

Reliability Benefits:

- Reduced maintenance costs

- Fewer service calls

- Extended service life

- Improved safety

Performance Advantages:

- Consistent electrical performance

- Weather independence

- Corrosion resistance

- Reduced downtime

Troubleshooting Common Issues

Water Ingress Problems

Symptoms:

- Intermittent electrical faults

- Ground fault circuit breaker trips

- Corrosion at connections

- Reduced insulation resistance

Solutions:

- Improve sealing methods

- Replace damaged sections

- Upgrade connection types

- Install drainage systems

Mechanical Damage

Prevention:

- Proper cable protection

- Adequate support systems

- Correct installation depth

- Regular inspection schedules

Future Trends and Innovations

Advanced Materials

New Insulation Technologies:

- Cross-linked polyethylene improvements

- Silicone compound advances

- Fluoropolymer developments

- Composite jacket materials

Smart Wire Technologies:

- Integrated monitoring systems

- Self-healing materials

- Temperature-sensing capabilities

- Fault location systems

Environmental Considerations

Sustainable Options:

- Recyclable jacket materials

- Lead-free constructions

- Environmentally friendly manufacturing

- Energy-efficient production methods

Maintenance and Inspection

Regular Maintenance Schedule

Monthly Checks:

- Visual inspection for damage

- Connection tightness verification

- Moisture detection

- Performance testing

Annual Inspections:

- Comprehensive system testing

- Insulation resistance measurement

- Thermal imaging analysis

- Documentation updates

Testing Methods

Insulation Testing:

- Megohm meter testing

- Hipot testing procedures

- Ground fault detection

- Continuity verification

Conclusion

Waterproof wire is essential for reliable electrical installations in wet, outdoor, and marine environments. Selecting the appropriate type based on environmental conditions, electrical requirements, and application needs ensures long-term performance and safety.

Whether you're installing landscape lighting, marine electrical systems, or industrial equipment, understanding the various types of waterproof wire and their applications helps you make informed decisions. Proper installation techniques, quality connections, and regular maintenance are crucial for maximizing the benefits of waterproof wire systems.

Investing in quality waterproof wire may cost more initially, but the long-term reliability, safety, and reduced maintenance make it a cost-effective choice for any application exposed to moisture or harsh environmental conditions. Always consult with electrical professionals for complex installations and ensure compliance with local electrical codes and regulations.

Remember that while waterproof wire provides excellent protection against moisture, proper installation and sealing of connections are equally important for system reliability and safety.