Selecting the correct wire gauge for 15 amp circuits is fundamental to home electrical safety and code compliance. As the most common residential circuit type, understanding 15 amp wire requirements helps ensure safe installations for lighting, outlets, and small appliances throughout your home.

what gauge wire for 15 amp

Quick Answer: Wire Gauge for 15 Amp Circuits

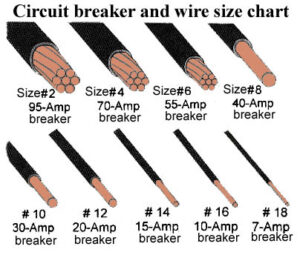

For standard 15 amp electrical circuits, you need:

- 14 AWG copper wire for most residential applications

- 12 AWG aluminum wire (rarely used in residential branch circuits)

- 12 AWG copper wire for long runs or special conditions

14 AWG copper wire is the standard and most cost-effective choice for typical 15 amp circuit installations.

Understanding 15 Amp Wire Requirements

The National Electrical Code (NEC) requires that wire ampacity must equal or exceed the circuit breaker rating. For 15 amp circuits, 14 AWG copper wire with an ampacity of 20 amps under standard conditions provides adequate capacity with a built-in safety margin.

Standard Wire Ampacity Ratings:

- 14 AWG copper: 20 amps (derated to 15 amps for circuit protection)

- 12 AWG copper: 25 amps (can handle 15 amp loads easily)

- 12 AWG aluminum: 20 amps (equivalent to 14 AWG copper)

This safety margin ensures the wire can handle the full 15 amp load without overheating under normal operating conditions.

Common Applications for 15 Amp Circuits

General Lighting Circuits

- Bedroom and living room lighting

- Hallway and stairway lights

- Ceiling fans and light fixtures

- Closet and utility lighting

- Outdoor landscape lighting

Standard Outlet Circuits

- Bedroom and living room outlets

- Home office receptacles

- General purpose outlets

- Table and floor lamp outlets

- Electronics and entertainment centers

Small Appliance Circuits

- Coffee makers and toasters (non-kitchen)

- Television and stereo equipment

- Computer workstations

- Charging stations for devices

- Small workshop tools

Specialty Applications

- Doorbell and chime circuits

- Security system wiring

- Intercom systems

- Low-power ventilation fans

- Smoke detector circuits

Why 14 AWG Wire is Standard for 15 Amp Circuits

Code Compliance

The NEC specifically allows 14 AWG copper wire for 15 amp circuits because:

- Wire ampacity (20 amps) exceeds circuit rating (15 amps)

- Provides adequate safety margin for normal use

- Meets temperature and installation requirements

- Balances safety with cost-effectiveness

Cost Effectiveness

14 AWG wire offers economic advantages:

- Lower material costs than larger wire sizes

- Easier installation due to smaller size

- Fits standard electrical boxes and connectors

- Widely available at all electrical suppliers

Installation Benefits

- Flexibility: Easier to bend and route through walls

- Box fill: Takes up less space in electrical boxes

- Weight: Lighter weight for overhead installations

- Compatibility: Works with all standard 15 amp devices

When to Use 12 AWG Wire Instead

Long Distance Runs

Consider 12 AWG wire when:

- Over 100 feet: Voltage drop becomes significant

- Critical equipment: Sensitive electronics need stable voltage

- Lighting circuits: Prevents dimming due to voltage drop

- Motor loads: Small motors require stable voltage

High Ambient Temperatures

Upsize to 12 AWG in:

- Hot attics: Summer temperatures exceed 86°F

- Bundled cables: Multiple circuits in same conduit

- Direct sunlight: Outdoor installations in hot climates

- Insulated areas: Where heat buildup is concern

Future-Proofing Installations

Use 12 AWG for:

- Potential upgrades: May want 20 amp circuits later

- Load growth: Anticipating increased electrical demands

- Code changes: Staying ahead of potential code updates

- Flexibility: Easier modifications in the future

Wire Types for 15 Amp Installations

Romex/NM Cable (Non-Metallic)

- 14-2 NM: Two conductors plus ground (most common)

- 14-3 NM: Three conductors plus ground (three-way switches)

- Residential standard: Most common for home wiring

- Easy installation: Pre-assembled cable with integrated ground

THWN Individual Conductors

- Conduit installations: Used with metal or PVC conduit

- Commercial applications: Often required in commercial buildings

- Wet locations: Suitable for damp or wet environments

- Color coding: Helps identify circuit conductors

MC Cable (Metal Clad)

- Flexible metal sheathing: Provides physical protection

- Exposed installations: Good for unfinished areas

- Fire resistance: Metal armor provides fire protection

- Commercial preference: Often specified in commercial work

Armored Cable (AC/BX)

- Traditional installation: Older but still code-compliant

- Retrofit work: Good for older home renovations

- Physical protection: Steel armor protects conductors

- Grounding through armor: Uses metal sheathing for ground

Installation Methods and Best Practices

Running Through Walls

- Drill center of studs: Avoid weakening structural members

- Use nail plates: Protect cables less than 1.25' from edge

- Proper stapling: Support cable every 4.5 feet

- Box connections: Secure cable within 8 inches of boxes

Conduit Systems

- Proper fill: Don't exceed conduit fill capacity

- Pulling technique: Use proper cable pulling methods

- Wire protection: Avoid damage during installation

- Grounding: Install separate grounding conductor

Surface-Mounted Installation

- Cable protection: Use appropriate cable guards

- Proper support: Support every 4-6 feet as required

- Neat appearance: Professional-looking installation

- Accessibility: Maintain access for future maintenance

Code Requirements and Safety Standards

National Electrical Code Compliance

- Wire ampacity: Must meet minimum capacity requirements

- Installation methods: Follow approved wiring practices

- Grounding requirements: Proper equipment grounding

- Box fill calculations: Don't overfill electrical boxes

Local Code Variations

- Permit requirements: Many areas require permits

- Inspection schedules: Rough-in and final inspections

- Professional licensing: Some work requires licensed electricians

- Special requirements: Local amendments to NEC

GFCI and AFCI Protection

Modern code requirements include:

- GFCI protection: Required in bathrooms, kitchens, outdoors

- AFCI protection: Required in bedrooms and living areas

- Combination devices: GFCI/AFCI combination breakers

- Testing requirements: Monthly testing recommended

Common Installation Mistakes to Avoid

Wire Sizing Errors

- Using 16 AWG: Not approved for 15 amp circuits

- Mixing wire sizes: Don't mix 14 and 12 AWG in same circuit

- Ignoring voltage drop: Not considering long run effects

- Wrong ampacity: Misunderstanding wire capacity ratings

Connection Problems

- Loose connections: Leading cause of electrical fires

- Wrong terminals: Using wrong wire nuts or connectors

- Poor workmanship: Sloppy connections create hazards

- Mixed materials: Improper copper/aluminum connections

Code Violations

- Missing permits: Installing without required permits

- Improper methods: Not following approved installation practices

- Overcrowded boxes: Exceeding box fill capacity

- Missing protection: Not installing required GFCI/AFCI devices

Planning Your 15 Amp Circuit Installation

Load Calculations

- List all devices: Identify everything on the circuit

- Calculate amperage: Add up all electrical loads

- Apply safety factor: Keep total under 12 amps (80% rule)

- Consider future needs: Plan for additional devices

Circuit Layout Design

- Logical grouping: Group related outlets and lights

- Minimize wire runs: Shorter runs save money and reduce voltage drop

- Access considerations: Plan for future maintenance

- Code compliance: Meet outlet spacing and GFCI requirements

Material Planning

- Wire quantity: Measure runs and add 20% extra

- Box selection: Choose appropriate box sizes

- Hardware needs: Wire nuts, staples, and connectors

- Safety equipment: GFCI and AFCI protection devices

Cost Analysis for 15 Amp Wire Installation

Material Costs (per foot)

- 14-2 Romex: $0.50-1.00

- 14-3 Romex: $0.75-1.25

- 14 AWG THWN: $0.25-0.50 (plus conduit costs)

- Electrical boxes: $2-10 per box depending on type

Installation Cost Factors

- DIY installation: Materials only, $50-200 per circuit

- Professional installation: $150-400 per circuit typically

- Permit fees: $50-150 depending on jurisdiction

- Complexity factors: Finished walls cost more than new construction

Long-term Value

- Safety investment: Proper wiring prevents fire hazards

- Code compliance: Meets current electrical standards

- Home value: Professional electrical work adds property value

- Energy efficiency: Proper sizing minimizes energy losses

Safety Guidelines for DIY Installation

Before Starting Work

- Turn off power: Always disconnect power at breaker

- Verify power off: Use voltage tester to confirm

- Plan the work: Layout circuit path and materials needed

- Check local codes: Understand permit and inspection requirements

During Installation

- Use proper tools: Insulated tools and safety equipment

- Follow codes: Adhere to NEC and local requirements

- Make good connections: Tight, properly made connections

- Test your work: Verify continuity before energizing

After Installation

- Professional inspection: Consider having work inspected

- Test all devices: Verify proper operation of outlets and switches

- Label circuits: Identify circuits in electrical panel

- Document work: Keep records of electrical modifications

Troubleshooting 15 Amp Circuit Issues

Breaker Problems

- Frequent tripping: Circuit overload or short circuit

- Won't reset: Serious fault requiring investigation

- Warm breaker: Loose connections or overloaded circuit

- Buzzing sounds: Arcing or loose connections

Outlet and Switch Issues

- No power: Check breaker and GFCI devices

- Intermittent operation: Loose connections likely

- Warm outlets: Overloading or poor connections

- Sparking: Stop use immediately and investigate

Performance Problems

- Dimming lights: Voltage drop or overloaded circuit

- Flickering: Loose connections or failing devices

- Reduced appliance performance: Voltage or connection issues

- Unusual sounds: Arcing or equipment problems

Maintenance and Long-term Care

Regular Inspections

- Visual checks: Look for signs of overheating or damage

- Test GFCI devices: Monthly testing recommended

- Check connections: Tighten accessible connections periodically

- Monitor loads: Don't overload circuits with too many devices

Professional Maintenance

- Electrical inspections: Every 10-15 years for older homes

- Thermal imaging: Professional inspection for hot spots

- Load analysis: Verify circuits aren't overloaded

- Code updates: Ensure system meets current codes

Modern Electrical Considerations

Smart Home Integration

- Smart switches: Consider compatibility with smart devices

- USB outlets: Plan for device charging needs

- Home automation: Integration with control systems

- Energy monitoring: Smart breakers for usage tracking

Future Technology

- Electric vehicle charging: May affect overall electrical loads

- Energy storage: Battery systems and electrical demands

- Renewable energy: Solar panels and system integration

- Increased electronics: Growing electrical demands in homes

Environmental and Efficiency Considerations

Energy Efficiency

- Proper wire sizing: Minimizes energy losses

- Quality materials: Use high-grade wire and connections

- LED lighting: Modern lighting reduces circuit loads

- Energy monitoring: Track and optimize electrical usage

Sustainable Practices

- Material selection: Choose environmentally responsible products

- Waste reduction: Minimize wire waste during installation

- Recycling: Properly dispose of old electrical materials

- Efficiency upgrades: Consider energy-efficient electrical devices

Conclusion

Using 14 AWG copper wire for 15 amp circuits provides safe, code-compliant electrical service for most residential lighting and outlet applications. This standard wire size offers the right balance of safety, cost-effectiveness, and ease of installation for typical home electrical needs.

While 15 amp circuits are among the simpler electrical installations, proper wire sizing, installation techniques, and code compliance remain essential for safety. Whether you're doing DIY electrical work or hiring professionals, understanding 15 amp wire requirements helps ensure your electrical system is safe and reliable.

Always consult local electrical codes and consider professional installation for complex projects or when you're unsure about requirements. Proper electrical installation protects your home and family while providing reliable electrical service for years to come.

Frequently Asked Questions

Q: Can I use 12 AWG wire on a 15 amp circuit? A: Yes, 12 AWG wire can be used on 15 amp circuits. It's oversized but perfectly safe and may be beneficial for long runs or high-temperature conditions.

Q: What happens if I use 16 AWG wire on a 15 amp circuit? A: Never use 16 AWG wire on 15 amp circuits. It's not rated for this amperage and creates a fire hazard. Always use 14 AWG or larger.

Q: How many outlets can I put on a 15 amp circuit? A: While there's no specific limit, practical considerations suggest 8-10 outlets maximum, depending on expected loads and circuit length.

Q: Do I need GFCI protection on all 15 amp circuits? A: GFCI protection is required in specific locations like bathrooms, kitchens, garages, and outdoor areas, but not necessarily on all 15 amp circuits.

Q: Can I install 15 amp circuits myself? A: Many jurisdictions allow homeowner installation of basic 15 amp circuits, but check local codes for permit and inspection requirements. Consider professional installation for complex work.