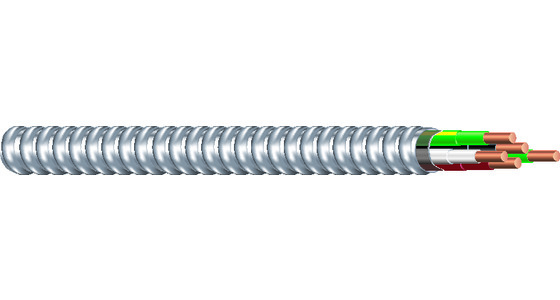

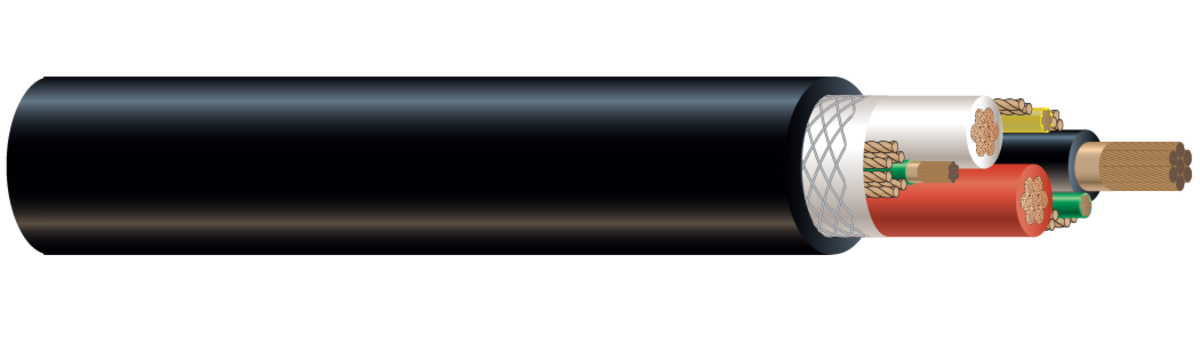

Continuous flex cable, also known as high-flex cable or drag chain cable, is a specially designed electrical cable engineered to withstand millions of flexing cycles without failure. These cables are ideal for applications where the cable is constantly moving, bending, or twisting — especially in automated machinery, robotics, and drag chains (energy chains).

continuous flex cable

What Makes a Cable 'Continuous Flex'?

Unlike standard industrial cables, continuous flex cables are built to resist mechanical fatigue over long service lives. Key features include:

-

Fine-stranded conductors (Class 6 or finer) for maximum flexibility

-

Tight-lay stranding and short pitch length to reduce friction

-

High-performance insulation and jacket materials like PUR, TPE, or PVC

-

Layered or bundled construction that reduces torsional stress

-

Resistance to oil, abrasion, and chemical exposure

These cables are typically tested to survive 5 million to over 10 million flexing cycles in drag chain testing environments.

Common Applications for Continuous Flex Cables

Continuous flex cables are essential for any application where motion, vibration, or repeated bending occurs:

-

Cable carriers / drag chains / energy chains

-

Robotic arms and automation

-

CNC machines and machine tools

-

3D printers and pick-and-place equipment

-

Logistics and packaging lines

-

High-speed conveyors

They are particularly common in automated production environments, where downtime due to cable failure can be costly.

Continuous Flex Cable vs. Regular Cable

| Feature | Continuous Flex Cable | Regular Cable |

|---|---|---|

| Stranding | Extra-fine stranded (Class 6+) | Class 5 or solid conductors |

| Flex Life | 5–10 million cycles | <500,000 cycles |

| Installation | Dynamic, moving parts | Static or limited movement |

| Jacket Resistance | Superior (abrasion, oil) | Standard |

| Cost | Higher upfront, lower TCO | Lower upfront, higher maintenance |

Bottom line: Regular cables are not built to flex repeatedly. Using standard cable in flexing environments will lead to conductor breakage, insulation cracking, and machine failure.

Popular Types of Continuous Flex Cables

-

PUR Continuous Flex Cable – Excellent for high abrasion environments

-

PVC Continuous Flex Cable – Budget-friendly, suitable for medium duty

-

Shielded Continuous Flex Cable – EMI/RFI protection for signal lines

-

TPE Flex Cable – Resistant to oil, chemicals, cold temperatures

-

Ethernet Continuous Flex Cable – For data transfer in moving applications

How to Choose the Right Continuous Flex Cable

When selecting a continuous flex cable, consider:

-

Bending radius – Cable should match your system’s minimum radius

-

Travel distance and speed – Affects cable fatigue

-

Tensile and torsional stress

-

Temperature range – Some environments require cold-resistant or heat-resistant jackets

-

Chemical/oil exposure – Use PUR or TPE when needed

-

Shielding needs – Necessary in signal or data transmission lines

For best results, choose cables that have been tested in continuous motion systems and verified with flex cycle ratings.

Shop Continuous Flex Cables

At TOT Wire & Cable, we offer a wide selection of industrial-grade continuous flex cables for automation, robotics, and dynamic machinery. Our cables are:

✅ Tested for over 10 million flexing cycles

✅ Resistant to oil, UV, and mechanical wear

✅ Available in PVC, PUR, and TPE jacket options

✅ Customizable conductor counts and shielding

Contact us today for product specs, custom options, or bulk pricing.