Electrical conduit is a protective tube or raceway system that houses electrical wires, shielding them from physical damage, moisture, and environmental hazards while providing a neat, organized wiring installation. Unlike cable systems like Romex (NM-B) or BX that come with built-in protective sheathing, conduit is an empty pipe that you pull individual insulated wires through—offering superior protection and flexibility for future wiring changes.

Conduit isn't just about protection—it's often required by electrical code. Commercial buildings, outdoor installations, exposed wiring in garages, and underground circuits typically mandate conduit use. Understanding when conduit is required versus when cable is acceptable can save you from code violations, failed inspections, and potentially dangerous installations.

what is a conduit

Whether you're planning a garage workshop, running power to a shed, or just trying to understand why your electrician specified metal conduit instead of simple Romex, this guide explains everything you need to know about electrical conduit systems.

What Is Conduit in Electrical Wiring?

Basic Definition

Electrical conduit is a channel or pipe designed to protect and route electrical wiring. It serves as:

- Physical protection: Guards wires from impact, crushing, and abrasion

- Environmental protection: Shields from moisture, chemicals, and UV exposure

- Fire protection: Contains fire and prevents wire combustion from spreading

- Organization: Keeps wiring neat, traceable, and maintainable

Conduit vs Cable: The Key Difference

CONDUIT SYSTEM CABLE SYSTEM (Romex/BX)

┌─────────────────┐ Individual wires

│ Empty pipe │ already bundled

│ installed first │ and protected

└────────┬────────┘ │

│ ▼

┌────┴─────┐ ┌──────────────┐

│ Pull │ │ ● Black wire │

│ wires │ │ ● White wire │

│ through │ │ ● Bare ground│

│ later │ │ All in jacket│

└──────────┘ └──────────────┘

│ │

▼ ▼

More flexible Single-run only

Future upgrades Pre-assembled

Code-required many Residential use

places

| Feature | Conduit System | Cable System |

|---|---|---|

| Installation | Two-step (conduit, then wires) | Single-step (cable includes wires) |

| Protection level | Maximum (metal/thick plastic) | Good (thin jacket) |

| Future changes | Easy (pull new wires) | Difficult (replace entire cable) |

| Cost | Higher (materials + labor) | Lower |

| Code approval | Accepted everywhere | Limited locations |

| Flexibility | Can add circuits later | Fixed capacity |

Why Is Conduit Used?

Primary Reasons for Conduit

1. Code Requirements

- Required in commercial buildings

- Mandatory for exposed wiring

- Required outdoors in many cases

- Underground installations

2. Physical Protection

- High-traffic areas

- Industrial environments

- Mechanical rooms

- Locations subject to impact

3. Environmental Protection

- Wet or damp locations

- Corrosive environments

- Direct sunlight exposure

- Underground burial

4. Future Flexibility

- Can add circuits without opening walls

- Pull new wires through existing conduit

- Upgrade wire capacity easily

- Adapt to changing needs

5. Fire Safety

- Contains electrical fires

- Prevents fire spread through wire pathways

- Meets strict fire codes

- Required in fire-rated assemblies

Types of Electrical Conduit

Different applications require different conduit types. Here's a comprehensive breakdown:

1. EMT (Electrical Metallic Tubing)

Description: Thin-walled steel tubing, most common type

EMT CONDUIT

┌─────────────────────────┐

│ ○○○○○○○○○○○○○○○○○○○ │ ← Thin steel wall

│ │ (not threaded)

└─────────────────────────┘

Connected with compression

or set-screw fittings

Characteristics:

- Material: Galvanized steel

- Wall thickness: Thin (about 0.04-0.05')

- Weight: Lightest metal conduit

- Connections: Compression or set-screw fittings

- Threading: Cannot be threaded (too thin)

Where to use:

- ✅ Indoor dry locations

- ✅ Indoor damp locations (with proper fittings)

- ✅ Exposed indoor installations

- ✅ Commercial buildings

- ✅ Residential exposed wiring

Where NOT to use:

- ❌ Direct burial underground

- ❌ Embedded in concrete

- ❌ Severe corrosive environments

- ❌ Outdoor exposed to weather (without protection)

Advantages:

- Economical (cheapest metal conduit)

- Easy to bend and work with

- Good physical protection

- Can be grounded through conduit

Disadvantages:

- Not suitable for wet locations

- Cannot be threaded

- Less durable than rigid

Common sizes: 1/2', 3/4', 1', 1-1/4', 1-1/2', 2'

Typical cost: $1-3 per 10-foot length (1/2'-3/4')

2. IMC (Intermediate Metal Conduit)

Description: Thicker-walled steel, between EMT and Rigid

Characteristics:

- Material: Galvanized steel

- Wall thickness: Medium (thicker than EMT, thinner than Rigid)

- Weight: Medium

- Connections: Threaded

- Threading: Can be threaded

Where to use:

- ✅ Outdoor installations

- ✅ Wet locations

- ✅ Embedded in concrete

- ✅ Areas requiring maximum protection

- ✅ Industrial environments

Advantages:

- Lighter than Rigid with similar protection

- Can be threaded for watertight connections

- Approved for concrete embedment

- Good for outdoor use

Disadvantages:

- More expensive than EMT

- Heavier and harder to work with

- Requires threading equipment

Common sizes: 1/2' to 4'

Typical cost: $3-5 per 10-foot length (1/2'-3/4')

3. Rigid Metal Conduit (RMC)

Description: Thick-walled steel, maximum protection

RIGID METAL CONDUIT

┌─────────────────────────┐

│ ████○○○○○○○○○○○████ │ ← Thick steel wall

│ ████○○○○○○○○○○○████ │ (threaded ends)

└─────────────────────────┘

Heavy-duty, threaded

connections

Characteristics:

- Material: Galvanized steel or stainless steel

- Wall thickness: Thick (0.109' for 1/2')

- Weight: Heaviest

- Connections: Threaded (NPT)

- Threading: Designed to be threaded

Where to use:

- ✅ Underground burial (direct)

- ✅ Embedded in concrete

- ✅ Hazardous locations

- ✅ Outdoor exposed

- ✅ Areas subject to severe physical damage

- ✅ Industrial plants

Advantages:

- Maximum physical protection

- Can be directly buried

- Excellent grounding path

- Long service life

Disadvantages:

- Most expensive

- Heaviest (difficult to handle)

- Requires threading

- Labor-intensive installation

Common sizes: 1/2' to 6'

Typical cost: $8-15 per 10-foot length (1/2'-3/4')

4. PVC Conduit (Schedule 40 and Schedule 80)

Description: Rigid plastic conduit

PVC CONDUIT

┌─────────────────────────┐

│ ○○○○○○○○○○○○○○○○○○○ │ ← PVC plastic

│ │ (gray or white)

└─────────────────────────┘

Glued connections with

PVC cement

Schedule 40 (Standard Wall):

- Thinner wall

- Most common

- Suitable for most applications

Schedule 80 (Thick Wall):

- Thicker, stronger wall

- Required where subject to physical damage

- More expensive

Characteristics:

- Material: PVC plastic

- Weight: Very light

- Connections: Solvent-welded (glued)

- Corrosion: Completely corrosion-proof

Where to use:

- ✅ Underground burial (most common use)

- ✅ Embedded in concrete

- ✅ Corrosive environments

- ✅ Outdoor (UV-resistant gray)

- ✅ Damp/wet locations

Where NOT to use:

- ❌ Exposed indoors (unless Schedule 80)

- ❌ High-temperature locations

- ❌ As equipment grounding conductor path

- ❌ Where subject to physical damage (unless Sch 80)

Advantages:

- Inexpensive

- Lightweight (easy to handle)

- Never corrodes

- Easy to cut and assemble

- Excellent for underground

Disadvantages:

- Cannot serve as ground (must pull ground wire)

- Brittle in cold weather

- Not suitable for high temperatures

- UV degrades white PVC (use gray)

Common sizes: 1/2' to 6'

Typical cost: $1-2 per 10-foot length Schedule 40 (1/2'-3/4')

5. Flexible Metal Conduit (FMC / 'Greenfield')

Description: Flexible spiral-wound metal

FLEXIBLE CONDUIT

╔═══════════════════╗

║ ▓▓▓▓▓▓▓▓▓▓▓▓▓▓▓ ║ ← Interlocking steel

╚═══════════════════╝ spiral (flexible)

Can bend without fittings

Characteristics:

- Material: Spiral-wound galvanized steel

- Flexibility: Bends easily by hand

- Connections: Special FMC connectors

- Grounding: Limited (often requires separate ground)

Where to use:

- ✅ Short runs to motors or equipment

- ✅ Locations requiring flexibility

- ✅ Connections to vibrating equipment

- ✅ Indoor dry locations

Where NOT to use:

- ❌ Wet locations (use LFMC)

- ❌ Long runs (high wire-pulling friction)

- ❌ Buried or embedded

- ❌ Corrosive environments

Advantages:

- Easy to route around obstacles

- No bending tools needed

- Good for final connections to equipment

Disadvantages:

- More expensive than EMT

- Limited grounding capability

- Higher wire-pulling friction

Common sizes: 3/8', 1/2', 3/4', 1'

6. Liquid-Tight Flexible Metal Conduit (LFMC)

Description: Flexible conduit with waterproof plastic coating

Characteristics:

- Similar to FMC but with PVC jacket

- Waterproof

- Used outdoors and in wet locations

Where to use:

- ✅ Outdoor equipment connections

- ✅ Wet locations

- ✅ HVAC equipment connections

- ✅ Pump and motor leads

Conduit Type Comparison Table

| Type | Cost | Protection | Flexibility | Common Use |

|---|---|---|---|---|

| EMT | $ | Good | Rigid (bendable) | Indoor exposed |

| IMC | $$ | Excellent | Rigid | Outdoor, concrete |

| Rigid | $$$ | Maximum | Rigid | Underground, industrial |

| PVC Sch 40 | $ | Good | Rigid | Underground, wet |

| PVC Sch 80 | $$ | Excellent | Rigid | Exposed, underground |

| FMC | $$ | Good | Flexible | Equipment connections |

| LFMC | $$$ | Good | Flexible | Outdoor equipment |

Conduit for Electrical Wiring: When Is It Required?

NEC (National Electrical Code) Requirements

The National Electrical Code specifies when conduit is required:

Always Requires Conduit

Commercial and industrial buildings:

- All exposed wiring

- Most concealed wiring

- Service entrances

Outdoor installations:

- Exposed wiring (EMT minimum, Rigid preferred)

- Underground wiring (PVC or Rigid)

- On building exteriors

Wet and damp locations:

- Bathrooms (exposed wiring)

- Laundry rooms (exposed)

- Outdoors

- Underground

Garages and unfinished spaces:

- Exposed wiring below 8 feet

- Subject to physical damage

Concrete embedment:

- Wiring in concrete slabs

- Buried under concrete

Cable (Romex/BX) May Be Acceptable

Residential applications:

- Inside walls and ceilings (Romex)

- Protected from damage

- Dry locations only

Specific exceptions:

- One and two-family dwellings

- Multifamily residential units (interior)

- Finished spaces

Quick Decision Guide

Where is the wiring?

│

├─► COMMERCIAL BUILDING → Conduit required

│

├─► OUTDOORS → Conduit required

│

├─► UNDERGROUND → Conduit required (PVC/Rigid)

│

├─► EXPOSED (visible) → Conduit required

│ │

│ └─► Exception: Residential basement/attic

│ where protected

│

├─► IN CONCRETE → Conduit required

│

└─► RESIDENTIAL, inside walls/ceilings

│

└─► Romex acceptable (if dry location)

Wire Types Used in Conduit

Conduit uses individual insulated wires, not cable:

THHN/THWN Wire (Most Common)

THHN:

- Thermoplastic

- Heat resistant

- High heat resistant

- Nylon coated

- Dry locations, 90°C rated

THWN:

- Same as THHN plus

- Water resistant

- Wet locations approved

- Most versatile (dry or wet)

THHN/THWN:

- Rated for both (dual-rated)

- Most common choice

- Available in all colors

Wire Color Coding

| Wire Color | Function |

|---|---|

| Black | Hot (line/phase) |

| Red | Hot (second phase or switch leg) |

| Blue | Hot (third phase) |

| White | Neutral |

| Green | Ground |

| Bare copper | Ground |

How Many Wires in Conduit?

Conduit fill rules (NEC Article 314):

- Maximum 40% fill for 3+ wires

- Prevents overheating

- Allows wire pulling without damage

Example: 1/2' EMT conduit:

- Nine 12 AWG THHN wires maximum

- Six 10 AWG THHN wires maximum

Conduit Installation Basics

Tools Needed

For metal conduit:

- Conduit cutter or hacksaw

- Conduit bender (for EMT)

- Reamer (deburr cut ends)

- Fish tape (pull wires)

- Wire pulling lubricant

For PVC conduit:

- PVC cutter or hacksaw

- PVC cement and primer

- Heat gun (for bending, optional)

Basic Installation Steps

1. Plan the route

- Minimize bends (maximum four 90° bends between boxes)

- Support requirements (every 10 feet for EMT)

- Box locations

2. Install conduit

- Cut to length

- Deburr cut ends

- Bend as needed (EMT) or use fittings

- Secure with straps/supports

- Install boxes and fittings

3. Pull wires

- Use fish tape

- Apply wire pulling lubricant

- Pull smoothly (don't jerk)

- Leave 6-8' extra at each box

4. Make connections

- Strip wire ends

- Connect devices and fixtures

- Secure wires in boxes

- Test circuits

Conduit in Electrical Wiring: Common Applications

Underground Wiring

Best choice: PVC Schedule 40 or Rigid metal

Requirements:

- Minimum burial depth:

- 24' for rigid/IMC

- 18' for PVC

- 6' if protected by concrete

- Use individual THWN wires

- Include ground wire (PVC doesn't ground)

Outdoor Surface Wiring

Best choice: IMC or Rigid metal

Requirements:

- Waterproof fittings

- Weather-resistant boxes

- LFMC for final equipment connections

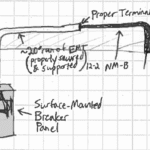

Garage and Workshop

Best choice: EMT (exposed) or Romex (concealed)

Requirements:

- Conduit required below 8 feet (subject to damage)

- Romex acceptable above 8 feet or concealed

- Proper support spacing

Commercial Buildings

Best choice: EMT (most common)

Requirements:

- All wiring typically in conduit

- Proper fill calculations

- Fire-rated assemblies

- ADA-compliant box heights

Conduit vs Cable Systems

Conduit System Advantages

✅ Maximum protection

✅ Future wire changes (pull new wires easily)

✅ Code compliant everywhere

✅ Professional appearance

✅ Fire-resistant

✅ Can serve as ground (metal conduit)

Conduit System Disadvantages

❌ Higher material cost

❌ More labor-intensive

❌ Two-step installation

❌ Requires more skill

❌ Heavier and bulkier

When to Choose Cable Instead

Choose Romex (NM-B) when:

- Residential interior wiring

- Inside walls and ceilings

- Dry locations

- Lower budget

- DIY installation

Choose BX/MC cable when:

- Residential exposed in dry locations

- Some commercial applications

- Moderate protection needed

- Faster than conduit, better than Romex

Common Conduit Installation Mistakes

| Mistake | Why It's Wrong | Correct Approach |

|---|---|---|

| Too many bends | Creates wire-pulling problems | Maximum 4 × 90° between boxes |

| Overfilling conduit | Overheats, damages insulation | Follow NEC fill tables (40% max) |

| Not deburring cuts | Sharp edges cut wire insulation | Always ream cut ends |

| Wrong conduit for location | Code violation, premature failure | Match conduit type to environment |

| No pulling lubricant | Damages wire insulation | Use approved lubricant for long pulls |

| Improper support | Sagging, stress on connections | Support every 10' (EMT), 3' (FMC) |

| Using PVC as ground | Unsafe—no ground path | Always pull separate ground wire |

Frequently Asked Questions

Can I run Romex through conduit?

Technically yes, but not recommended. Romex in conduit:

- Takes up more space (larger conduit needed)

- Harder to pull (jacket creates friction)

- Individual THHN wires are better choice

Use individual wires (THHN/THWN) in conduit instead.

Do I need a ground wire in metal conduit?

It depends:

- Metal conduit (EMT, IMC, Rigid): Can serve as ground (with proper connections), but running separate ground wire is best practice

- PVC conduit: MUST include separate ground wire (PVC doesn't conduct)

Best practice: Always run a separate ground wire regardless of conduit type.

How deep does underground conduit need to be?

NEC minimum depths:

- Rigid/IMC: 6' (with concrete protection) to 24' (direct burial)

- PVC Schedule 80: 18' minimum

- Under driveway: 24' minimum (any type)

Always check local codes—they may be more stringent.

Can I use PVC conduit indoors?

Yes, with restrictions:

- Schedule 80 PVC approved for exposed indoor use

- Schedule 40 PVC limited to concealed locations

- Must pull separate ground wire

- Cannot be used where subject to physical damage

EMT is more common for indoor exposed wiring.

What size conduit do I need?

Depends on:

- Number of wires

- Wire gauge (AWG)

- NEC fill tables (Chapter 9, Table 4)

Quick estimate:

- 1/2' conduit: up to 9 × 12 AWG wires

- 3/4' conduit: up to 16 × 12 AWG wires

- 1' conduit: up to 26 × 12 AWG wires

Always verify with NEC fill tables for exact installation.

Conclusion

Electrical conduit provides the highest level of protection for electrical wiring and is often required by code for commercial buildings, outdoor installations, and exposed wiring. While more expensive and labor-intensive than cable systems like Romex or BX, conduit offers unmatched durability, safety, and future flexibility.

Key takeaways:

- EMT is most common for indoor commercial and residential exposed wiring

- PVC Schedule 40 is the standard for underground residential wiring

- Rigid metal provides maximum protection for industrial and outdoor exposed installations

- Conduit is required for commercial buildings, outdoor wiring, underground runs, and exposed locations

- Use individual THHN/THWN wires in conduit, not cable

- Always include a separate ground wire in PVC conduit

- Follow NEC fill requirements (maximum 40% for 3+ wires)

Understanding when conduit is required versus when cable is acceptable ensures code-compliant installations that protect your electrical system for decades.

Planning an electrical installation? Always consult local electrical codes and consider hiring a licensed electrician for complex conduit installations. Improper electrical work can be dangerous and violate building codes.